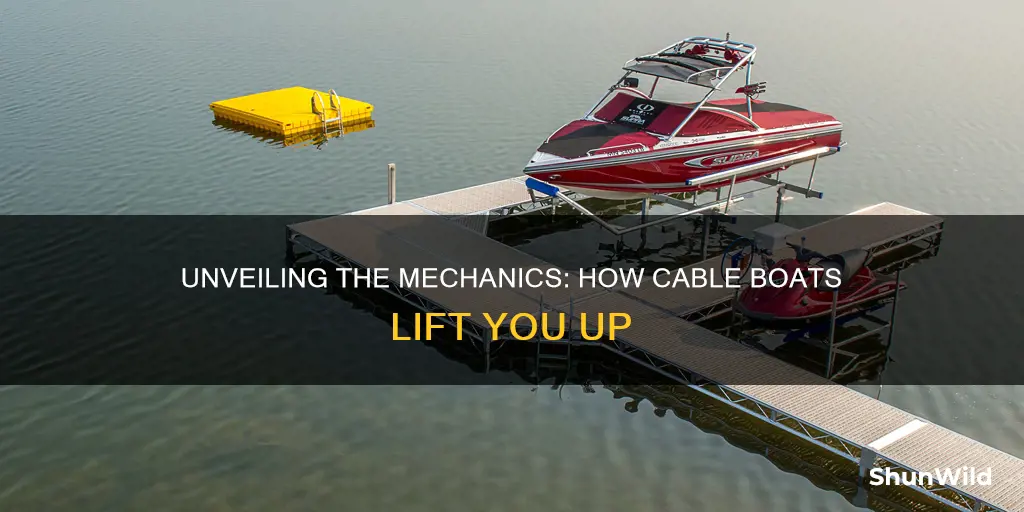

Cable boats, also known as cable-operated lifts or cable-assist systems, are innovative transportation solutions that utilize cables to move boats vertically. This technology is particularly useful in areas with limited space, such as narrow canals or rivers, where traditional boat lifts may not be feasible. The operation of a cable boat lift involves a series of mechanical components working in harmony. A series of pulleys and cables are used to lift and lower the boat, often with the help of a motor or hydraulic system. The boat is secured to the cable, which is then wound around the pulley system, allowing for controlled movement. This mechanism ensures a smooth and efficient vertical transportation process, making it a popular choice for various water-based transportation needs.

What You'll Learn

- Hydraulic Systems: Powerful pumps and cylinders lift the boat

- Mooring Mechanisms: Ropes and anchors secure the boat in place

- Cable Tension: Tensioning systems maintain cable stability and strength

- Counterweights: Balancing weights ensure the boat's stability and buoyancy

- Control Panels: Operators control the lift using intuitive interfaces

Hydraulic Systems: Powerful pumps and cylinders lift the boat

Hydraulic systems are a crucial component of cable boat lifts, providing the necessary force to lift and lower boats efficiently. These systems utilize the power of pressurized fluid, typically oil, to generate significant lifting capacity. At the heart of this process are powerful pumps and cylinders, which work in harmony to achieve the desired elevation.

The process begins with a high-pressure pump, often driven by an electric motor, which pumps oil through a network of pipes and hoses. This pressurized fluid is then directed towards hydraulic cylinders strategically positioned along the lift's guide rails. These cylinders are designed to convert the fluid's pressure into mechanical force, enabling the lift to ascend or descend.

When the lift is in the lowering position, the pump is activated, forcing oil into the hydraulic cylinders. The pressurized fluid extends the cylinders, causing the lift to move downward. This action is controlled by a series of valves and check valves, ensuring that the fluid flows in the correct direction and preventing backflow. The power of the hydraulic system lies in its ability to exert substantial force over a relatively short distance, making it ideal for lifting heavy loads.

As the boat is lifted, the hydraulic cylinders retract, pulling the lift upward. This movement is facilitated by the controlled release of pressure from the cylinders, allowing the fluid to flow back to the pump. The system's design ensures a smooth and precise lift, accommodating various boat sizes and weights. By adjusting the pressure and flow rate of the pump, operators can fine-tune the lifting speed and force, making the hydraulic system versatile and adaptable.

In summary, hydraulic systems play a vital role in cable boat lifts by employing powerful pumps and cylinders to generate the necessary lifting force. This technology enables efficient and controlled elevation, ensuring the safe and smooth transport of boats. The precision and power of hydraulic systems make them an indispensable component in modern boat-lifting applications.

Repairing Flaky Areas on Your Boat: A Comprehensive Guide

You may want to see also

Mooring Mechanisms: Ropes and anchors secure the boat in place

Mooring a boat effectively is crucial for safety and stability, especially when using a cable boat lift. The process involves a combination of ropes and anchors to secure the vessel in place, ensuring it remains stationary and controlled during operations. Here's a detailed breakdown of the mooring mechanisms:

Ropes: High-strength ropes are essential for mooring, providing the necessary tension and control. These ropes are typically made from durable materials like polyester or nylon, designed to withstand the forces exerted by the boat and the lift cables. The ropes are attached to the boat at specific points, often along the sides or at the stern, and are then secured to the mooring system. When mooring, the ropes are strategically placed to create a stable and secure hold. One common technique is to use a combination of bow and stern lines. Bow lines are run from the bow of the boat to the mooring posts or anchors, providing a forward tension that prevents the boat from drifting backward. Stern lines, on the other hand, are attached to the stern and also secured to the mooring system, creating a backward-pulling force that keeps the boat in place. The angles and lengths of these lines are carefully calculated to ensure optimal tension and stability.

Anchors: Anchors play a critical role in the mooring process, providing a solid foundation for the rope system. They are typically heavy, robust structures designed to hold significant tension and resist the forces of the water. When mooring, anchors are positioned at strategic points, often on the bottom of the river or lake. One common type of anchor used in this context is the fluked anchor, which has multiple 'flukes' or sharp edges that grip the seabed. These anchors are driven into the substrate, providing a secure hold. The anchors are connected to the ropes using sturdy chains or anchor lines, which are then attached to the boat's mooring points. This setup ensures that the boat remains firmly in place, even during adverse weather conditions or strong currents.

The mooring process requires careful planning and consideration of various factors, including the boat's size, weight, and the environmental conditions. By utilizing ropes and anchors effectively, operators can ensure that the boat is securely moored, ready for safe and efficient operations with the cable boat lift. This setup provides a reliable and controlled environment for loading and unloading cargo, making it an essential aspect of efficient port operations.

Protect Your Boat: Avoid Dock Post Collisions and Scrapes

You may want to see also

Cable Tension: Tensioning systems maintain cable stability and strength

Cable tension is a critical aspect of cable-based lifting systems, ensuring the structural integrity and safety of the entire setup. Tensioning systems are designed to maintain optimal cable tension, which is essential for several reasons. Firstly, proper tensioning prevents cable sag, which could lead to reduced lifting capacity and potential damage to the system. Sagging cables can also create a safety hazard, especially in dynamic environments where the cables might experience vibrations or movements.

The tensioning process involves several key components. One common method is the use of tensioning pulleys or drums, which are strategically placed along the cable route. These pulleys are designed to apply tension to the cable by winding it around their grooved surfaces. The tensioning process typically begins with the cable being pulled through the system, often using a motorized or manual winch, to a predetermined length. Once the desired length is achieved, the tensioning pulley is engaged, and the cable is wound onto the drum, creating tension.

Another important aspect of tensioning systems is the use of tensioning anchors or anchors. These anchors are fixed points along the cable route, providing a solid base for applying tension. They are typically secured to a sturdy structure, such as a pier or a fixed support, ensuring that the tensioning process is stable and secure. Tensioning anchors are crucial for maintaining the cable's position and preventing it from shifting or sagging over time.

Regular maintenance and monitoring of cable tension are essential to ensure the system's longevity and safety. This includes periodic inspections to check for any signs of wear, damage, or corrosion, especially in areas where the cables are exposed to harsh environmental conditions. Adjustments and re-tensioning may be required if the cable's tension changes due to various factors, such as temperature variations or the addition of new loads.

In summary, cable tensioning systems play a vital role in the functionality and safety of cable boat lifts. By maintaining optimal tension, these systems ensure the stability and strength of the cables, allowing for efficient and secure lifting operations. Proper tensioning, combined with regular maintenance, contributes to the overall reliability and performance of such lifting mechanisms.

Boat Wake: How Far Does It Really Travel?

You may want to see also

Counterweights: Balancing weights ensure the boat's stability and buoyancy

The concept of counterweights is fundamental to the operation of cable boat lifts, ensuring the system's stability and buoyancy. These lifts are designed to transport boats vertically along a cable, and counterweights play a crucial role in maintaining equilibrium and preventing the boats from capsizing.

Counterweights are typically heavy structures attached to the bottom of the boat or the lift mechanism. Their primary function is to provide a downward force that counteracts the upward buoyant force exerted by the water. By carefully calculating the weight and placement of these counterweights, engineers can achieve a stable equilibrium, allowing the boat to float securely on the water's surface while being lifted or lowered.

The design and positioning of counterweights are critical to the system's success. They must be strategically placed to balance the boat's weight and the tension of the lifting cable. This balance ensures that the boat remains level and stable throughout the lifting process, even when it is partially submerged in water. The counterweights' weight distribution should be optimized to minimize any potential tilting or shifting of the boat, which could compromise its stability.

In addition to stability, counterweights contribute to the overall buoyancy of the system. By providing a counterweight, the boat's effective weight is reduced, allowing it to float more easily. This is particularly important when the boat is partially filled with water or cargo, as the counterweights help maintain its buoyancy even when it is not fully loaded.

The use of counterweights in cable boat lifts is a sophisticated engineering solution that ensures the safe and efficient transportation of boats. It showcases the delicate balance between weight, buoyancy, and stability, all of which are essential for the successful operation of such lifting systems.

Boat Neck Bra Conundrum: What's the Best Bra to Wear?

You may want to see also

Control Panels: Operators control the lift using intuitive interfaces

The operation of a cable boat lift is a fascinating engineering feat, and at the heart of this system are the control panels that enable operators to manage the lift's functionality. These panels are designed with a user-friendly approach, ensuring that operators can effortlessly control the lift's movement and various functions.

Upon approaching the control panel, operators are greeted with a visually appealing and well-organized interface. The panel typically features a large display screen, often a touchscreen, which serves as the primary control center. This screen provides a comprehensive overview of the lift's current status, including real-time data on the boat's position, speed, and any relevant sensors' readings. The interface is designed to be intuitive, with clear icons and labels, making it easy for operators to understand the lift's current state.

Operators can initiate the lifting process by selecting the desired boat and inputting relevant details such as weight, size, and intended destination. The control panel then calculates the required cable tension and speed to ensure a smooth and safe lift. This calculation is based on pre-programmed algorithms and real-time data, allowing for precise control. Once the input is confirmed, the lift begins, and the operator can monitor the progress on the screen.

During the lift, the control panel provides continuous feedback. It displays the boat's ascent or descent speed, cable tension, and any adjustments made to maintain stability. Operators can make fine-tunings to the lift's parameters, such as adjusting the cable speed or tension, to accommodate varying boat sizes and weights. This level of control ensures that the lift can handle a wide range of vessels efficiently and safely.

Additionally, the control panel offers various safety features. It can detect and prevent overloading, alerting operators to any potential issues. In the event of an emergency, the panel provides quick access to emergency stop buttons, allowing operators to halt the lift immediately. These safety measures are crucial in maintaining the integrity of the system and ensuring the well-being of operators and passengers.

In summary, the control panels of a cable boat lift are designed with operator convenience and safety in mind. The intuitive interfaces enable operators to effortlessly manage the lift's functions, from initiating the lift to monitoring its progress and making adjustments. With a focus on user-friendliness and safety, these control panels play a vital role in the efficient and secure operation of cable boat lifts.

Understanding Boat Scuppers: How They Work and Why

You may want to see also

Frequently asked questions

A cable boat lift, also known as a cable ferry or cable-stayed lift, is a type of transportation system used to carry boats or vehicles across a body of water. It operates by using a series of cables and pulleys to lift and lower the boats. The process begins with a cable running along a guide rail on the shore, which is anchored at both ends. This cable is then connected to a series of sheaves or pulleys, often mounted on a sturdy tower or structure. When a boat approaches the lift, it is secured to the cable using a special mooring system. The operator then pulls the cable, which winds around the pulleys, lifting the boat up and over the water. This method is particularly useful for narrow waterways or areas with limited space, as it requires less depth and width compared to traditional ferry systems.

The main components of a cable boat lift include the cable itself, which is typically made of strong materials like steel or synthetic fibers. The cable is designed to withstand tension and provide the necessary lifting force. Pulleys or sheaves are crucial, as they change the direction of the cable's pull, allowing the boat to be lifted. These pulleys are often arranged in multiple levels to create a mechanical advantage and ensure smooth operation. Additionally, a robust mooring system is essential to secure the boat to the cable and prevent it from slipping. This system may include hooks, rings, or specialized fittings that attach to the cable.

Absolutely, safety is a critical aspect of cable boat lift operations. These lifts are equipped with various safety features to ensure the well-being of both the boats and their occupants. One important measure is the use of emergency stop mechanisms, which can be activated in case of sudden cable failure or other emergencies. These stops can quickly release the tension on the cable, bringing the boat to a safe position. Additionally, cable boat lifts often have weight limits and size restrictions to ensure they can handle the intended load without compromising safety. Regular maintenance and inspections are also conducted to identify and rectify any potential issues, making the lifting process as secure as possible.