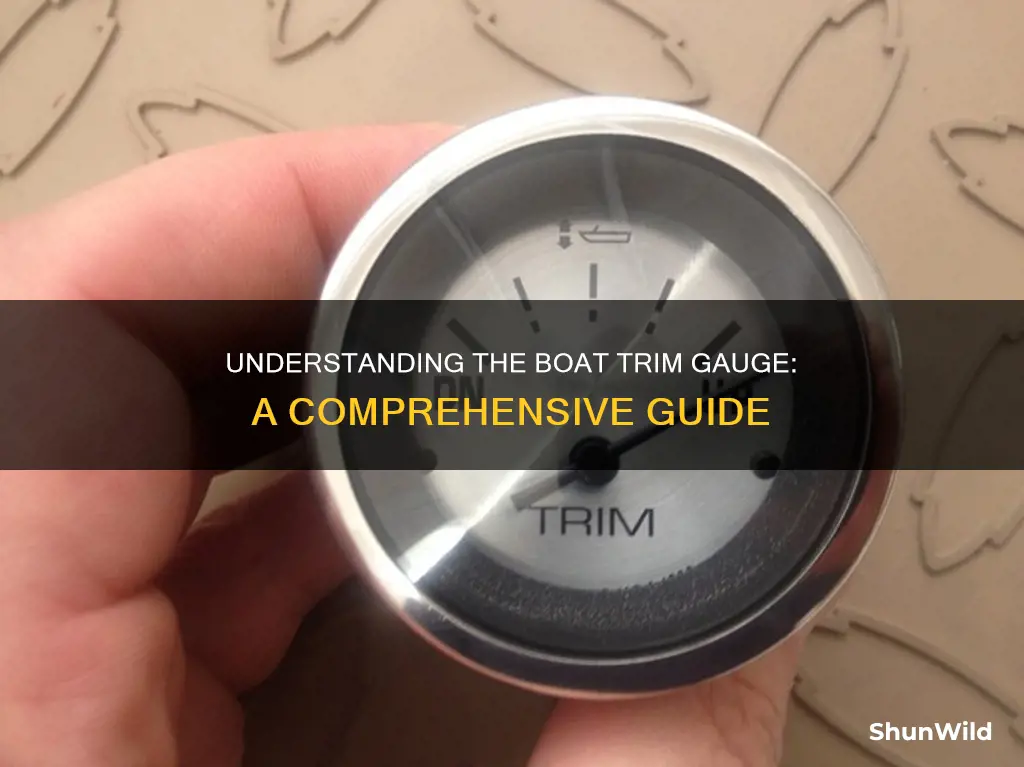

A boat trim gauge is an essential instrument for monitoring the angle of a boat's hull relative to the water, known as trim. This gauge provides valuable information to the operator, allowing them to adjust the boat's trim to optimize performance, stability, and fuel efficiency. By measuring the angle of the hull, the gauge helps the operator understand how the boat is sitting in the water, enabling them to make precise adjustments to the trim tabs or rudders to achieve the desired trim. Understanding how a boat trim gauge works is crucial for safe and efficient boating, as it ensures the boat is operating at its best and can help prevent issues related to trim, such as poor handling or excessive drag.

What You'll Learn

- Pressure Sensors: These measure water pressure to determine the boat's trim angle

- Trim Control: The gauge displays the boat's trim angle and allows for manual adjustment

- Hydraulic Systems: Hydraulics are often used to adjust the boat's trim

- Electronic Feedback: Sensors provide real-time data to the gauge for accurate readings

- Calibration: Calibration ensures the gauge accurately reflects the boat's trim

Pressure Sensors: These measure water pressure to determine the boat's trim angle

Pressure sensors are a crucial component in understanding and controlling the trim of a boat. These sensors are strategically placed in the boat's hull, often near the waterline, to measure the pressure exerted by the water. The primary function of these sensors is to provide real-time data on the boat's trim angle, which is the angle at which the boat sits in the water. This information is vital for several reasons. Firstly, it helps the boat's computer system or the operator to make precise adjustments to the boat's trim, ensuring it remains level and stable. This is especially important when navigating through varying water conditions or when carrying different loads.

The operation of pressure sensors is based on the principle of hydrostatic pressure. As the boat displaces water, the pressure increases in proportion to the depth of the water. By measuring this pressure, the sensor can calculate the boat's trim angle. This is achieved through a process of calibration, where the sensor is programmed to recognize the pressure changes associated with different trim angles. When the boat is level, the pressure sensors will detect a specific pressure reading, and any deviation from this reading indicates a change in trim.

In the context of a trim gauge, pressure sensors play a critical role in providing feedback to the system. When the boat's computer or the operator adjusts the trim, the sensors immediately respond to these changes. For instance, if the boat is trimmed down, the pressure sensors will detect a decrease in pressure, indicating that the boat has moved to a lower position in the water. Conversely, if the boat is trimmed up, the sensors will measure an increase in pressure, signifying a higher trim angle. This real-time data allows for immediate adjustments to be made, ensuring the boat maintains its desired trim.

The accuracy of pressure sensors is essential for safe and efficient boat operation. Modern boats often use advanced sensor technology, including digital pressure transducers, which offer high precision and reliability. These transducers convert the measured pressure into an electrical signal, which is then processed by the boat's control system. This system can make rapid adjustments to the trim, ensuring the boat remains stable and responsive to the operator's commands.

In summary, pressure sensors are integral to the functionality of a boat trim gauge, providing the necessary data to determine the boat's trim angle. By measuring water pressure, these sensors enable precise control over the boat's trim, ensuring it remains level and stable in various conditions. This technology has significantly contributed to the safety and performance of boats, allowing for better handling and an improved overall boating experience.

Boat Paint vs Gelcoat: What's the Best Option?

You may want to see also

Trim Control: The gauge displays the boat's trim angle and allows for manual adjustment

The trim gauge is an essential component of a boat's navigation and performance system, providing critical information about the vessel's trim angle. This gauge is designed to offer a clear and precise indication of the boat's current trim position, which is the angle at which the hull is inclined relative to the waterline. Understanding and controlling this trim angle is crucial for optimizing a boat's performance, stability, and handling characteristics.

When a boat is in motion, its trim angle is constantly changing due to various factors such as speed, load, and sea conditions. The trim gauge is strategically placed in the boat's cabin, often within easy reach of the captain or operator. It typically consists of a needle or digital display that moves or changes color to indicate the current trim angle. This real-time feedback allows the operator to make immediate adjustments to ensure the boat is in the optimal trim position for the given conditions.

The manual adjustment feature of the trim gauge is a powerful tool for fine-tuning the boat's performance. By turning a knob or pressing a button, the operator can increase or decrease the boat's trim angle. This action directly impacts the boat's stability and handling. For example, raising the bow (front) of the boat increases trim angle, making it more stable and suitable for high-speed cruising or rough waters. Conversely, lowering the bow decreases trim angle, which is ideal for planing or gliding over the water, especially in calm conditions.

Trim control is particularly important when a boat is loaded with passengers or cargo, as this can significantly affect its trim. The gauge ensures that the operator can make quick adjustments to maintain the desired trim, ensuring a comfortable and safe ride. Additionally, in racing or performance-oriented boats, precise trim control can be the difference between winning and losing, or simply achieving the best possible performance.

In summary, the trim gauge with manual adjustment capabilities is a vital instrument for any boat owner or operator. It provides a clear visual representation of the boat's trim angle, allowing for immediate and precise control. This feature enables operators to optimize their vessel's performance, stability, and handling, ensuring a smooth and efficient journey on the water. Understanding and utilizing this gauge effectively can significantly enhance the overall boating experience.

Mastering the Art of Backing a Single-Engine Boat

You may want to see also

Hydraulic Systems: Hydraulics are often used to adjust the boat's trim

Hydraulic systems play a crucial role in adjusting a boat's trim, which refers to the angle at which the boat sits in the water. This adjustment is essential for optimizing performance, fuel efficiency, and comfort, especially in larger vessels. The use of hydraulics in this context offers precise control and the ability to make quick adjustments, ensuring the boat can maintain the desired trim even in varying sea conditions.

In a hydraulic trim system, a pump is typically powered by the boat's engine or a dedicated motor. This pump is designed to create and control a flow of hydraulic fluid, which is then directed to actuators or cylinders located at the boat's hull. These actuators are strategically positioned to move the boat's keels, rudders, or other adjustable components, thus altering the trim. The pump's operation can be regulated by a control valve, allowing for fine-tuning of the hydraulic pressure and, consequently, the trim angle.

The beauty of hydraulic systems lies in their ability to provide smooth and precise control. By adjusting the flow of hydraulic fluid, the operator can gradually change the boat's trim, ensuring a seamless transition between different water conditions. This is particularly useful when navigating through varying depths or when adjusting for passenger comfort, as it allows for a gentle and controlled movement of the boat's structure.

One of the key advantages of hydraulic trim systems is their reliability and durability. These systems are designed to withstand the harsh marine environment, with components often made from corrosion-resistant materials. The use of hydraulic fluid further contributes to their longevity, as it acts as a lubricant and coolant, protecting the system's components from excessive wear and tear.

In summary, hydraulic systems offer a sophisticated and effective solution for adjusting a boat's trim. By utilizing the power of hydraulics, boat owners and operators can ensure optimal performance and comfort, even in challenging sea conditions. The precision and control provided by these systems make them an indispensable feature in modern boating, allowing for a seamless and efficient experience on the water.

Bass Boat Propeller Pitch: Understanding the Basics

You may want to see also

Electronic Feedback: Sensors provide real-time data to the gauge for accurate readings

The evolution of boat trim gauges has been significantly influenced by the integration of electronic feedback systems, which have revolutionized the way boaters monitor their vessel's trim. This technology relies on a network of sensors strategically placed throughout the boat, each serving a specific purpose. These sensors are the eyes and ears of the trim gauge, constantly gathering data and sending it back for analysis.

At the heart of this system are the sensors, which can be categorized into several types. One common type is the pressure sensor, which measures the force exerted by the water on the hull. This data is crucial as it directly correlates to the boat's trim angle, indicating whether the boat is sitting too high or too low in the water. Another essential sensor is the acceleration sensor, which detects changes in the boat's movement and orientation. By monitoring the boat's acceleration, it can provide feedback on how the vessel is responding to trim adjustments.

Electronic feedback systems also utilize sensors to measure the boat's pitch and roll angles. These sensors provide valuable information about the boat's attitude in relation to the water, helping to ensure that the trim is set at the optimal angle for stability and performance. For instance, if the boat is rolling excessively, the sensors can detect this and send the relevant data to the gauge, allowing the operator to make immediate adjustments to improve stability.

The real-time data provided by these sensors is then transmitted to the trim gauge, which processes this information to display accurate and up-to-date readings. This electronic feedback loop ensures that the gauge always shows the current trim angle, even as the boat moves or conditions change. For example, when a boat is underway, the sensors continuously monitor the water pressure and movement, and the gauge reflects these changes, providing the operator with a clear and dynamic view of the boat's trim.

This electronic approach to trim gauge functionality offers several advantages. Firstly, it provides a more accurate and immediate representation of the boat's trim, allowing operators to make swift adjustments to optimize performance and stability. Secondly, the real-time data ensures that the gauge is always current, even in varying sea conditions or when the boat is in motion. This level of precision and responsiveness is particularly beneficial for high-performance boats and those used in competitive racing, where every second count.

Winter Haven Boat Ramps: Open or Closed?

You may want to see also

Calibration: Calibration ensures the gauge accurately reflects the boat's trim

Calibration is a critical process in ensuring the accuracy and reliability of a boat trim gauge. It involves adjusting and fine-tuning the gauge's settings to match the specific characteristics of the boat it is measuring. This process is essential because each boat has unique trim angles and dynamics, and without proper calibration, the gauge may provide inaccurate readings.

The primary goal of calibration is to ensure that the gauge's display accurately represents the boat's trim angle. This is typically done by adjusting the gauge's sensitivity and response to the boat's movement. For example, a calibrated gauge should respond proportionally to the boat's trim, showing a clear and precise indication of the trim angle. This is crucial for boaters who rely on the gauge to make quick decisions regarding their vessel's stability and performance.

During calibration, the technician or user will often refer to the boat's specifications and manufacturer guidelines. These resources provide information on the expected trim range and the corresponding expected gauge readings. By comparing the gauge's output to these standards, any discrepancies can be identified and corrected. This may involve adjusting the gauge's zero-point, sensitivity, or response time to match the boat's unique characteristics.

Calibration can be performed in various ways, depending on the type of trim gauge and the boat's design. One common method is to use a trim test rig or a specialized calibration tool. These devices allow for controlled adjustments and measurements, ensuring that the gauge's calibration is precise and consistent. In some cases, a professional technician may be required to perform the calibration, especially for complex or high-performance boats.

Regular calibration is recommended to maintain the gauge's accuracy over time. Environmental factors, such as temperature changes and exposure to saltwater, can affect the gauge's performance. Therefore, periodic calibration ensures that the gauge remains reliable and provides accurate trim readings, even in varying conditions. Proper calibration is a fundamental aspect of boat trim gauge maintenance, ensuring safe and efficient boating operations.

The Mystery of Robert Card's Boat: Solved or Unsolved?

You may want to see also

Frequently asked questions

A boat trim gauge is an instrument that measures and displays the angle or position of the boat's hull relative to the water's surface. It is crucial for ensuring optimal performance and stability, especially in high-speed boats, as it helps the driver adjust the boat's trim to maintain balance and control.

The gauge is connected to sensors that monitor the boat's trim angle. These sensors send data to the gauge, which then displays the current trim reading. This allows the operator to make immediate adjustments to the boat's trim, ensuring it remains at the optimal position for speed and stability.

A boat can be trimmed in three main positions: planing, cruising, and displacement. Planing trim is used for high-speed operation, where the boat's hull is raised to reduce drag. Cruising trim is for efficient fuel consumption at lower speeds. Displacement trim is for deep-water conditions, keeping the boat stable and upright.

Yes, a trim gauge can alert the operator to potential problems. For instance, if the gauge shows an erratic or fluctuating reading, it may indicate a faulty sensor or a need for adjustment. A complete trim failure could lead to loss of control, so the gauge's feedback is vital for addressing such issues promptly.

Trim adjustments should be made regularly, especially when changing speeds or loads. Proper trim management improves boat handling, reduces fuel consumption, and enhances overall performance. It also ensures the boat remains safe and stable, especially in varying sea conditions.