A boat's RPM (revolutions per minute) gauge is an essential instrument for monitoring the engine's performance and ensuring safe operation. This gauge measures the speed of the engine's crankshaft, indicating the engine's rotational speed in revolutions per minute. By providing real-time data on engine speed, the RPM gauge helps boaters make informed decisions about throttle control, gear shifting, and overall engine management. Understanding how this gauge works is crucial for optimizing engine performance, preventing damage, and ensuring a smooth and safe boating experience.

What You'll Learn

- Engine Speed Measurement: The gauge measures engine revolutions per minute (rpm) to indicate speed

- Sensor Technology: Sensors convert engine speed into electrical signals for display

- Display Mechanism: A needle or digital readout shows the rpm value

- Calibration: Calibration ensures accurate readings across different engine speeds

- Safety Limits: The gauge alerts the operator to potential engine over-revving

Engine Speed Measurement: The gauge measures engine revolutions per minute (rpm) to indicate speed

The engine speed measurement on a boat is a critical component for monitoring the performance and health of the vessel's propulsion system. This gauge is designed to measure the revolutions per minute (rpm) of the engine, which directly translates to the boat's speed. By providing real-time data on engine speed, the gauge offers an essential tool for both operators and maintenance personnel.

At its core, the rpm gauge operates based on a simple principle: it counts the number of engine revolutions over a specific time interval. This is typically achieved using a magnetic sensor or a tachometer, which is connected to the engine's crankshaft. As the crankshaft rotates, it generates a magnetic field that interacts with the sensor, causing it to send electrical pulses to the gauge. The gauge then calculates the rpm by counting these pulses and dividing by the time interval. This process is highly accurate and provides a reliable measurement of the engine's rotational speed.

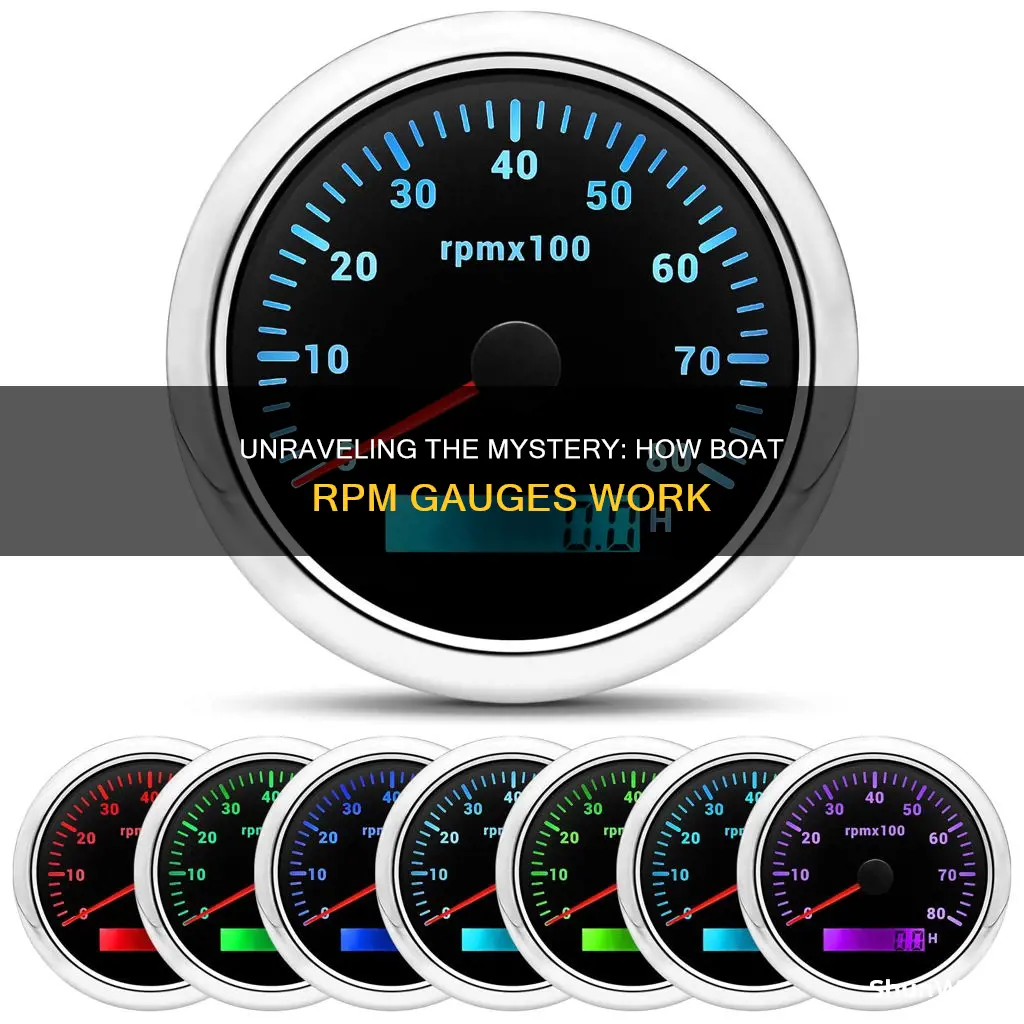

The display of the rpm gauge is usually a digital or analog meter, often located in a prominent position within the boat's dashboard or console. It presents the current rpm value, allowing the operator to quickly assess the engine's speed. Modern gauges may also include additional features such as a speed limit indicator, which can alert the operator when the engine exceeds a predetermined safe speed. This feature is particularly useful during high-performance maneuvers or when navigating through narrow channels.

In addition to speed indication, the rpm gauge offers valuable insights into the engine's performance and health. By monitoring the rpm, operators can ensure that the engine is running within optimal parameters. Excessive or insufficient rpm can indicate various issues, such as improper tuning, mechanical problems, or fuel system malfunctions. Regularly checking the rpm gauge helps identify potential problems early on, enabling prompt maintenance and preventing costly repairs.

Furthermore, the rpm gauge is an essential safety feature, especially in high-speed boating. It provides a visual warning if the engine speed exceeds safe limits, reducing the risk of engine damage or loss of control. This is particularly important when operating in changing weather conditions or when approaching tight turns, where maintaining precise speed control is crucial. Overall, the engine speed measurement gauge plays a vital role in ensuring the safe and efficient operation of a boat's propulsion system.

Hilma's Sailing Adventure: Exploring the Seas in Style

You may want to see also

Sensor Technology: Sensors convert engine speed into electrical signals for display

The heart of an RPM (revolutions per minute) gauge in a boat is the sensor technology that translates engine speed into a readable display. This process involves a few key components and a basic understanding of how they interact.

Sensors play a crucial role in this system. They are typically located near the engine and are designed to measure the rotational speed of the engine's crankshaft. This crankshaft is a vital component that converts the reciprocating motion of the pistons into rotational motion. By monitoring the crankshaft's speed, the sensor provides a direct measurement of the engine's RPM.

These sensors utilize various technologies, but one common method is inductive sensing. An inductive sensor consists of a coil of wire wrapped around a core. When the crankshaft rotates, it passes through the magnetic field generated by the coil. This interaction induces an electrical signal in the coil, proportional to the crankshaft's speed. This electrical signal is then transmitted to the gauge.

The electrical signal from the sensor is typically in the form of a varying current or voltage. This signal is then processed by the gauge's electronics. The gauge's display is controlled by this electrical input, which is converted into a visual representation of the engine's RPM. Modern gauges often feature digital displays, showing the RPM value directly.

In summary, the sensor technology in a boat's RPM gauge is a sophisticated process. It involves measuring the engine's crankshaft speed using inductive sensors, converting that speed into an electrical signal, and then translating that signal into a readable display. This system provides boat owners with valuable information about their engine's performance, ensuring they operate within safe and efficient parameters.

Sailing Spain: Miles from England's Coast

You may want to see also

Display Mechanism: A needle or digital readout shows the rpm value

The display mechanism of a boat's RPM (revolutions per minute) gauge is a crucial component that provides the driver with real-time information about the engine's performance. This gauge typically employs a needle or a digital readout to indicate the engine's rotational speed.

In the case of a needle gauge, it operates on a mechanical principle. The gauge consists of a small, lightweight needle that is connected to a gear system. This gear system is driven by a magnet or an electric motor, which is in turn powered by the engine's rotation. As the engine turns, the gear system rotates, causing the needle to move in proportion to the engine's RPM. The needle is usually marked with a scale, allowing the driver to quickly read the current RPM value. This type of gauge provides a simple and intuitive visual representation of the engine's speed.

Alternatively, modern boats often feature digital RPM gauges, which offer enhanced precision and readability. These gauges utilize an electronic sensor to measure the engine's rotational speed. The sensor converts the engine's RPM into an electrical signal, which is then processed by a microcontroller or a dedicated electronic module. This module displays the RPM value on a small LCD or LED screen, providing a clear and precise reading. Digital gauges often include additional features such as data logging, alarm settings, and the ability to display other engine parameters, making them a popular choice for modern vessels.

Both needle and digital RPM gauges serve the same purpose: to provide the operator with essential engine performance data. The choice between the two often depends on personal preference, the boat's design, and the level of detail required. Needle gauges offer a traditional and often more affordable option, while digital gauges provide advanced features and improved visibility, especially in low-light conditions.

In summary, the display mechanism of an RPM gauge is designed to provide a clear and immediate indication of the engine's speed. Whether it's a mechanical needle or a digital display, these gauges are essential tools for boat owners and operators, ensuring they can monitor and maintain their vessel's engine performance effectively.

Mama's Return: A Tale of the Unexpected

You may want to see also

Calibration: Calibration ensures accurate readings across different engine speeds

Calibration is a critical process in ensuring that your boat's RPM (revolutions per minute) gauge provides accurate and reliable readings, especially across a wide range of engine speeds. This process involves adjusting the gauge's settings to match the specific characteristics of your engine, ensuring that the displayed RPM values are precise and consistent. Here's a detailed look at how calibration works and its importance:

Understanding Engine Speeds: Before calibrating, it's essential to comprehend the relationship between engine speed and RPM. The RPM gauge measures the engine's rotational speed, which is directly proportional to its power output. When an engine operates at higher RPMs, it generates more power, and the gauge should reflect this accurately. Calibration ensures that the gauge's needle moves proportionally to the engine's speed, providing a clear and reliable indication of the engine's performance.

Calibration Process: Calibration typically involves the following steps:

- Engine Operation: Start by operating the engine at various speeds, covering a wide range of RPMs. This data will be used to calibrate the gauge.

- Reference Measurement: During engine operation, take note of the actual RPM values and the corresponding gauge readings. This reference data is crucial for calibration.

- Adjustments: Compare the gauge readings with the actual RPM values. If there are discrepancies, adjust the gauge's settings. This might include fine-tuning the sensitivity, zero-point calibration, and scaling.

- Repeat and Verify: Repeat the process at different engine speeds to ensure consistency. Verify that the gauge provides accurate readings across the entire RPM range.

Importance of Calibration: Proper calibration is vital for several reasons. Firstly, it ensures that the gauge provides an accurate representation of the engine's performance, which is essential for safe and efficient operation. Inaccurate readings can lead to incorrect decisions about engine speed and power, potentially causing damage or inefficiency. Secondly, calibration helps maintain the gauge's longevity. Over time, environmental factors and engine wear can affect the gauge's accuracy, and calibration ensures it remains reliable.

Regular Maintenance: Regular calibration is recommended, especially after significant engine modifications or when the gauge shows signs of wear. Environmental factors, such as temperature changes, can also impact the gauge's performance, making periodic calibration a good practice. By following these calibration procedures, you can ensure that your boat's RPM gauge provides accurate and consistent readings, contributing to better engine management and overall boating experience.

Hull Number Location on Crownline Boats: A Guide

You may want to see also

Safety Limits: The gauge alerts the operator to potential engine over-revving

A boat's RPM (revolutions per minute) gauge is a critical component designed to monitor and display the engine's rotational speed. It serves as an early warning system, alerting the operator to potential issues that could lead to engine damage or failure. One of its primary functions is to ensure the engine operates within safe limits, particularly in terms of RPM.

The RPM gauge is typically connected to the engine's speed sensor, which measures the engine's rotational speed and sends this data to the gauge. This real-time information allows the operator to have a clear understanding of the engine's performance. When the engine is running, the gauge displays the current RPM value, often with a green or normal range indicator. This range is usually set by the manufacturer and represents the optimal RPM for safe and efficient operation.

The safety limits are crucial as they prevent the engine from over-revving, which can cause significant damage. Over-revving occurs when the engine's RPM exceeds the safe limit, leading to increased stress on the engine components. This can result in premature wear and tear, reduced engine life, and even catastrophic failure. For example, if the engine is designed for a maximum RPM of 6000, exceeding this limit can cause the engine to overheat, the bearings to seize, or the pistons to hit the top of the cylinder walls.

In the event of an over-rev condition, the RPM gauge will typically flash or display an alert. This alert can be a visual warning, such as a red indicator light, or an audible signal, like a beeping sound. The operator should take immediate action upon receiving this alert, such as reducing the throttle input or shutting down the engine if necessary, to prevent further damage.

Modern boat engines often feature advanced RPM control systems that can automatically adjust the throttle to maintain the optimal RPM. These systems work in conjunction with the gauge, ensuring the engine operates within safe limits without the need for constant operator intervention. This technology is particularly useful for beginners or in situations where the operator may not be fully focused on the engine's performance.

Staying Safe: PFDs Required for Boating Emergencies

You may want to see also

Frequently asked questions

An RPM (Revolutions Per Minute) gauge is a vital instrument in a boat's dashboard, providing real-time data on the engine's rotational speed. It measures the number of engine revolutions per minute, which directly correlates to the engine's power output and overall performance. Monitoring RPM is crucial for safe and efficient boating, as it helps operators maintain optimal engine speed, ensuring the engine runs within its recommended operating range.

The RPM gauge works by measuring the electrical pulses generated by the engine's crankshaft position sensor. This sensor sends signals to the engine's electronic control unit (ECU), which then calculates the engine's speed in RPM. The gauge displays this information, typically in the form of a needle or digital readout, allowing the operator to quickly assess the engine's performance and make adjustments as needed.

Absolutely! An RPM gauge is a critical tool for preventing engine damage. Operating a boat at extremely high or low RPMs can lead to engine strain, reduced fuel efficiency, and potential mechanical issues. By monitoring the RPM gauge, operators can ensure the engine remains within a safe operating range, avoiding over-revving or under-performing situations that could cause long-term damage.

While RPM gauges are generally reliable, there are a few potential issues to be aware of. Calibration errors or faulty sensors can lead to inaccurate readings. Regular maintenance, such as checking and replacing sensors, can help ensure accurate performance. Additionally, keeping the gauge clean and free of debris is essential for optimal functionality. It's also recommended to have the gauge inspected by a professional during routine boat maintenance checks.