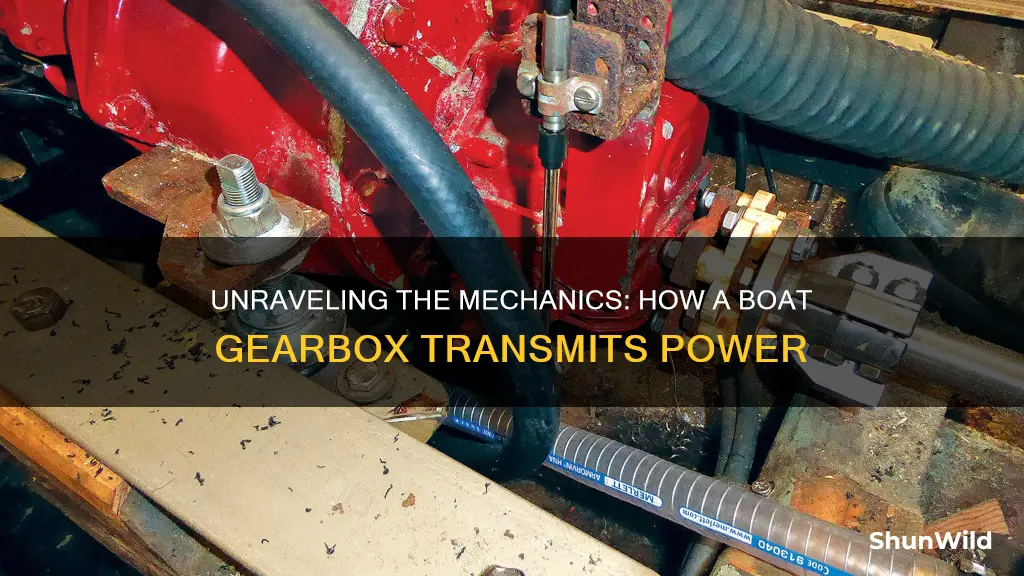

A boat gearbox, also known as a transmission, is a crucial component in marine vehicles, enabling the transfer of power from the engine to the propeller. It plays a vital role in controlling the speed and torque of the boat, allowing for efficient propulsion and maneuverability. Understanding the inner workings of a boat gearbox is essential for boat owners and operators to ensure optimal performance and longevity of their vessels. This paragraph will delve into the mechanics of how a boat gearbox operates, explaining the processes of gear selection, power transmission, and the role of different components such as the clutch, gears, and shifters.

What You'll Learn

- Gear Ratios: Boat gearboxes use different gear ratios to change speed and torque

- Power Transmission: The gearbox transfers power from the engine to the propeller

- Reverse Function: A reverse gear allows the boat to move backward

- Shift Mechanism: Operators shift gears using a lever or automatic system

- Lubrication: Proper lubrication ensures smooth operation and longevity of the gearbox

Gear Ratios: Boat gearboxes use different gear ratios to change speed and torque

A boat gearbox, also known as a transmission, is a crucial component in marine vehicles, responsible for transmitting power from the engine to the propeller, enabling the boat to move efficiently. One of the key principles that govern the functionality of a boat gearbox is the concept of gear ratios. Gear ratios are the relationship between the number of teeth on two meshed gears, which directly affects the speed and torque output.

In a boat gearbox, multiple sets of gears are arranged in a specific order, each with a unique number of teeth. When the engine's power is transferred through these gears, the rotation speed and torque are altered. The gear ratio determines how many times the propeller rotates for each complete turn of the engine's crankshaft. A higher gear ratio means the propeller rotates fewer times, resulting in higher speed but lower torque. Conversely, a lower gear ratio allows for more propeller rotations, providing more torque but at a reduced speed.

Boat gearboxes offer a range of gear ratios to accommodate various boating conditions and requirements. For instance, when a boat needs to accelerate quickly, a lower gear ratio is selected, providing higher torque to overcome inertia. This is often used during take-off or when towing heavy loads. On the other hand, when cruising at a steady speed, a higher gear ratio is chosen to maximize fuel efficiency and reduce engine strain.

The design of boat gearboxes allows for smooth power transmission and efficient use of the engine's power. By utilizing different gear ratios, the gearbox can adapt to changing boating scenarios, ensuring optimal performance and control. This adaptability is crucial for boaters, as it enables them to navigate through different water conditions, from calm lakes to rough seas, with ease and precision.

Understanding gear ratios is essential for boat owners and operators to maximize the performance and longevity of their marine vehicles. By selecting the appropriate gear ratio for specific tasks, boaters can optimize their vessel's capabilities, ensuring a smooth and efficient journey on the water.

Mastering Boat Docking: Techniques for Ultimate Control

You may want to see also

Power Transmission: The gearbox transfers power from the engine to the propeller

The boat's gearbox is a crucial component in the power transmission system, acting as a bridge between the engine and the propeller. Its primary function is to transmit the rotational force generated by the engine to the propeller, enabling the vessel to move through the water. This process involves a series of intricate mechanisms that ensure efficient power transfer.

When the engine is engaged, it rotates the crankshaft, which then drives the gearbox through a series of gears and shafts. The gearbox is designed with a specific gear ratio that matches the engine's output to the propeller's requirements. This ratio is carefully calculated to optimize speed and torque, allowing the boat to accelerate, decelerate, or maintain a steady speed as needed.

Within the gearbox, there are typically multiple gears arranged in a specific order. The input gear, connected to the crankshaft, meshes with the output gear, which is connected to the propeller shaft. As the engine rotates, the input gear spins, driving the output gear and, consequently, the propeller. This gear reduction process ensures that the propeller receives the appropriate amount of power to propel the boat efficiently.

The design of the gearbox also includes various lubricants and cooling systems to manage the heat generated during operation. These systems are essential to prevent overheating and ensure the longevity of the gearbox. Additionally, some boat gearboxes incorporate automatic shift mechanisms, allowing for seamless gear changes without manual intervention, which further enhances the overall performance and reliability of the power transmission system.

In summary, the gearbox plays a vital role in power transmission by converting the engine's rotational energy into a form that the propeller can utilize. Its intricate gear arrangement, lubrication, and cooling systems work in harmony to deliver the necessary power to the propeller, ensuring the boat's efficient and controlled movement through the water. Understanding these mechanisms is key to appreciating the complexity and importance of the boat's gearbox in marine propulsion systems.

Solo Sailing: Easy-to-Handle Boats for Beginners

You may want to see also

Reverse Function: A reverse gear allows the boat to move backward

The reverse function in a boat's gearbox is a crucial component that enables the vessel to move in the opposite direction, i.e., backward. This mechanism is particularly useful when maneuvering in tight spaces, docking, or when the boat needs to retreat from a dangerous situation. Understanding how this system works is essential for any boat owner or operator to ensure safe and efficient navigation.

In a boat's transmission system, the reverse gear is typically engaged by a specific gear or set of gears that are designed to interact with the propeller in a unique way. When the operator selects the reverse option, a series of intricate processes occur. Firstly, the gearbox shifts the drive train's direction, causing the propeller to rotate in the opposite direction. This is achieved through a clever arrangement of gears and clutches, which are carefully synchronized to ensure smooth and controlled movement. The propeller's rotation direction is reversed, allowing the boat to propel itself backward.

The design of the reverse gear is critical to its functionality. It often involves a set of gears with specific tooth profiles and sizes that are optimized for backward movement. These gears are carefully positioned and meshed to transmit the power from the engine to the propeller in reverse. The process is similar to the forward gear, but with a crucial difference in the direction of rotation, ensuring the boat moves in the desired direction.

Engaging the reverse gear requires precise control, as it demands a different set of skills compared to forward movement. Boat operators must carefully manage the throttle and steering to maintain stability and control during the backward maneuver. This is especially important when docking or navigating through narrow channels, where precision is key to avoiding obstacles or other vessels.

In summary, the reverse function in a boat's gearbox is a sophisticated mechanism that allows for backward movement. It involves a precise arrangement of gears and clutches to reverse the propeller's rotation, providing the boat with the ability to move in reverse. Understanding this system is vital for safe and efficient boating, ensuring operators can navigate various situations with confidence.

A Rough Reality Show: Don't Rock the Boat

You may want to see also

Shift Mechanism: Operators shift gears using a lever or automatic system

The shift mechanism is a crucial component of a boat's gearbox, allowing operators to change gears smoothly and efficiently. This mechanism is designed to facilitate the transition between different gear ratios, enabling the boat to accelerate, decelerate, and maintain speed effectively. There are two primary methods for operators to engage this mechanism: through a lever or an automatic system.

The lever shift mechanism is a traditional and widely used method. It typically consists of a handle or knob mounted on the boat's dashboard or console. When the operator pulls or pushes the lever, it engages a series of gears within the gearbox. Each pull or push corresponds to a specific gear ratio, allowing the operator to select the desired gear. This method provides a tactile and immediate response, making it easy for operators to feel when a gear shift has been successfully completed. The lever is often designed with a distinct feel or 'click' to indicate a gear change, ensuring the operator knows when to shift.

In contrast, automatic shift mechanisms eliminate the need for manual intervention. These systems use sensors, solenoids, and electronic controls to automatically select the appropriate gear based on the boat's speed, load, and driving conditions. When the operator engages the throttle, the automatic system analyzes the data and selects the optimal gear ratio. This process is seamless and requires no input from the operator, making it particularly useful for cruising or when the boat is under varying loads. Automatic systems can also include features like 'creep' mode, which allows the boat to move forward slowly at a low speed without the need for constant throttle input.

Both lever and automatic shift mechanisms are designed to ensure smooth gear changes, minimizing the impact of the shift on the boat's performance and ride quality. The choice between the two often depends on personal preference, the type of boating, and the specific requirements of the vessel. Lever systems offer a more traditional and direct approach, while automatic systems provide convenience and ease of use, especially in situations where manual gear changes might be challenging or time-consuming.

In summary, the shift mechanism is a critical aspect of a boat's gearbox, enabling operators to manage gear ratios effectively. Whether through a lever or an automatic system, this mechanism ensures that the boat can navigate various speeds and conditions efficiently, contributing to a smooth and controlled driving experience.

How to Securely Tie a Boat to a Dock

You may want to see also

Lubrication: Proper lubrication ensures smooth operation and longevity of the gearbox

The proper lubrication of a boat gearbox is a critical aspect of maintaining its performance and longevity. Gearboxes, also known as transmissions, are complex mechanical systems that transmit power from the engine to the propeller, enabling the boat to move. Without adequate lubrication, the gears, bearings, and other moving parts within the gearbox can suffer from excessive wear and friction, leading to premature failure.

Lubrication plays a vital role in reducing friction between the metal surfaces in contact. In a boat gearbox, this is particularly important due to the high-speed and load-bearing nature of its operation. The gears and bearings experience significant mechanical stress, and without proper lubrication, the metal-to-metal contact can lead to rapid wear and tear. This wear can result in gear tooth damage, reduced efficiency, and even complete gear failure, causing the boat to lose propulsion or experience difficulty in shifting gears.

The primary function of lubrication is to create a protective film between the moving parts, which helps to minimize direct contact and reduce the generation of heat. This protective layer also helps to carry away small particles of wear, preventing them from causing further damage. In a boat gearbox, the lubricant also acts as a coolant, dissipating heat generated during operation, which is crucial to prevent overheating and maintain optimal performance.

To ensure proper lubrication, it is essential to use the correct type and grade of lubricant. Boat gearboxes typically require specialized gear oils designed to withstand the high-pressure and high-temperature conditions within the system. These oils often contain additives that provide excellent anti-wear and anti-friction properties. Regularly checking the oil level and condition is also vital. Insufficient lubrication can lead to increased friction and wear, while over-lubrication can attract dirt and debris, potentially causing damage.

In summary, proper lubrication is the key to maintaining a boat gearbox's efficiency and extending its lifespan. It ensures smooth gear operation, reduces wear, and prevents overheating. Regular maintenance, including checking and replacing the lubricant as per the manufacturer's guidelines, is essential to keep the gearbox in optimal condition, ensuring reliable and efficient power transmission for the boat's propulsion system.

Forester Boats: A Founder's Vision and Legacy

You may want to see also

Frequently asked questions

A boat gearbox, also known as a marine transmission, is a crucial component in a vessel's propulsion system. It is responsible for transmitting power from the engine to the propeller, allowing the boat to move. The gearbox uses a series of gears and a clutch mechanism to adjust the speed and torque of the engine, enabling the boat to navigate at different speeds and handle various water conditions.

Gear selection in a boat gearbox is typically controlled by a shift lever or a series of gears. When the driver selects a specific gear, the gearbox engages the corresponding set of gears to match the desired speed and torque. Lower gears provide more torque for acceleration or climbing steep inclines, while higher gears offer higher speeds for cruising. The gearbox ensures a smooth power transfer, allowing the boat to efficiently move through the water.

The clutch is an essential part of the boat gearbox's functionality. It acts as a temporary disconnect between the engine and the gearbox, allowing for smooth gear changes. When engaged, the clutch connects the engine to the gearbox, transferring power. During gear shifts, the clutch disengages, providing a smooth transition without sudden stops or starts. This mechanism ensures that the boat can efficiently change gears while maintaining control and stability on the water.