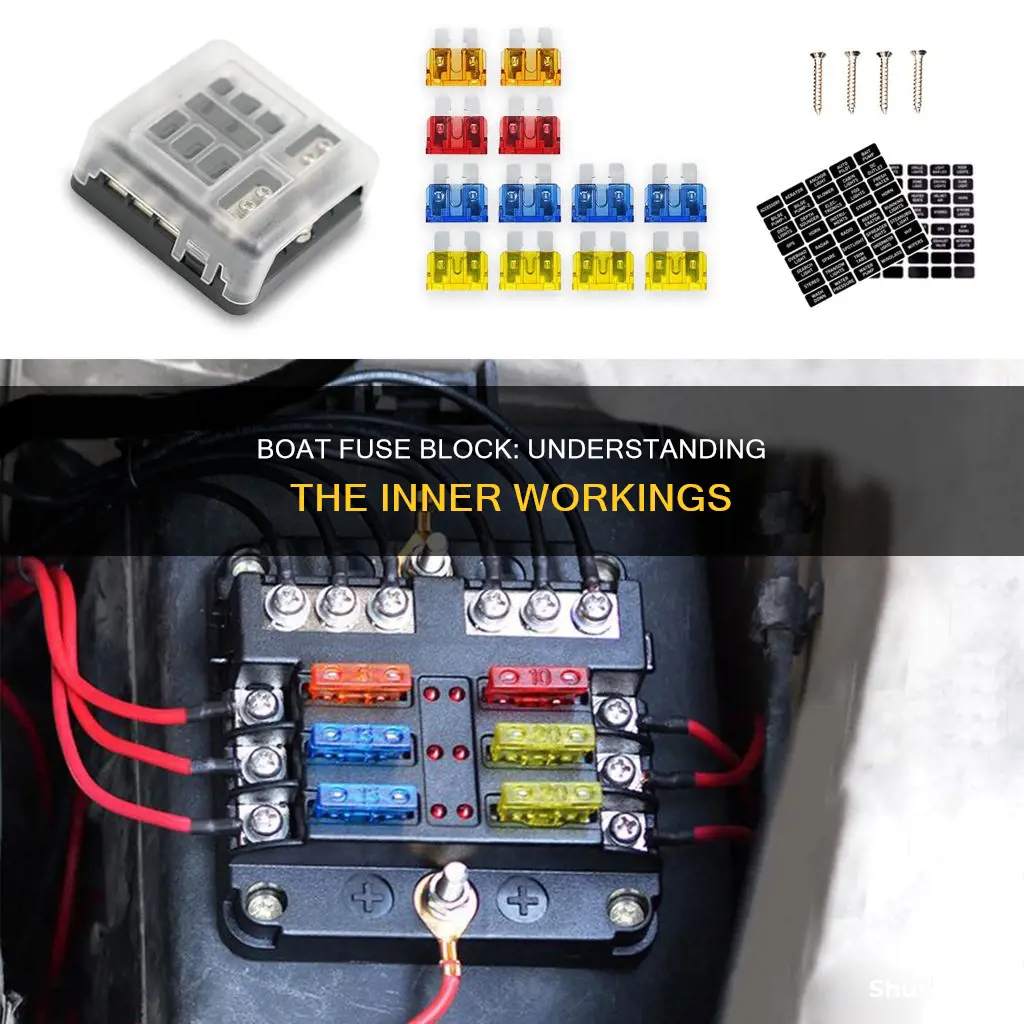

A boat fuse block is a crucial component in electrical systems, providing a safe and organized way to manage power distribution. It acts as a protective device, ensuring that electrical circuits are properly insulated and preventing overloading. The fuse block typically contains individual fuses, each designed to protect a specific circuit or component. When an electrical fault occurs, such as a short circuit or excessive current, the fuse's wire melts, interrupting the circuit and safeguarding the boat's electrical system. Understanding how a boat fuse block functions is essential for maintaining a safe and efficient power supply on board.

| Characteristics | Values |

|---|---|

| Function | A boat fuse block is a device that provides a safe and organized way to manage electrical connections on a boat. It acts as a central hub for wiring, allowing for easy access and protection against electrical faults. |

| Components | Typically, it consists of a plastic or metal housing, fuse holders, and a circuit breaker. The housing provides a protective enclosure, while the fuse holders hold the fuses in place, and the circuit breaker offers additional protection. |

| Fuse Types | Common fuse types include blade fuses, cartridge fuses, and blade-style fuses. Each type has a specific ampere rating and is designed to protect against overcurrent and short-circuit conditions. |

| Protection | Fuse blocks offer protection by interrupting the circuit when a fuse blows. This prevents damage to the boat's electrical system and ensures the safety of the vessel and its occupants. |

| Organization | They help organize wiring by providing a neat and accessible arrangement. Wires can be connected to the appropriate fuse, making it easier for boat owners and technicians to identify and troubleshoot issues. |

| Applications | Fuse blocks are commonly used in marine environments, power boats, sailboats, and other watercraft. They are essential for managing electrical systems, ensuring proper grounding, and providing circuit protection. |

| Installation | Installation involves mounting the fuse block in a convenient location, connecting wires to the appropriate fuse holders, and securing the block in place. It is crucial to follow manufacturer guidelines for proper installation. |

| Maintenance | Regular maintenance includes checking for blown fuses, replacing them if necessary, and ensuring the fuse block is clean and free from corrosion. Proper maintenance ensures the system's reliability. |

| Advantages | Advantages include improved safety, easier troubleshooting, and a more professional appearance. They also allow for quick replacement of fuses, reducing downtime in case of electrical issues. |

| Considerations | When choosing a fuse block, consider the boat's electrical requirements, the number of circuits, and the appropriate fuse sizes. It is essential to match the fuse block with the specific needs of the vessel. |

What You'll Learn

- Boat Fuse Block Basics: Understanding the core components and functions of a boat fuse block

- Fuse Types: Different types of fuses used in marine applications and their purposes

- Circuit Protection: How fuse blocks safeguard electrical circuits from overcurrent and short circuits

- Boat Electrical Systems: Overview of boat electrical systems and their reliance on fuse blocks

- Maintenance and Testing: Regular maintenance and testing procedures for optimal fuse block performance

Boat Fuse Block Basics: Understanding the core components and functions of a boat fuse block

A boat fuse block is a crucial component in a vessel's electrical system, providing a centralized and organized way to manage and protect the various circuits and devices on board. It is essentially a miniature electrical panel, designed to be mounted in a convenient location, often near the main switchboard or engine compartment. The primary function of a fuse block is to safeguard the electrical circuits from overcurrent, short circuits, and other potential faults, ensuring the safe operation of the boat's electrical systems.

The core components of a boat fuse block include individual fuses, a fuse holder or carrier, and a mounting assembly. Each fuse is designed to protect a specific circuit or device, and they are typically rated for the current they need to handle. When a circuit experiences an overcurrent condition, the fuse's wire melts, interrupting the circuit and preventing potential damage to the system. Fuse holders are small, insulated containers that securely hold the fuses, ensuring they remain in place and are easily accessible for replacement.

The fuse block's mounting assembly is designed to securely fasten the block to the boat's structure, ensuring it remains stable and does not shift during operation. This assembly often includes mounting holes and hardware to attach the block to the dashboard, bulkhead, or other suitable surfaces. Proper mounting is essential to ensure easy access for maintenance and to prevent the block from becoming a hazard if it were to become dislodged.

One of the key advantages of a fuse block is its ability to organize and simplify the electrical system. It allows for a clear visual representation of the boat's electrical layout, making it easier for boat owners and technicians to identify and troubleshoot issues. Each fuse in the block corresponds to a specific circuit, so when a fuse blows, it immediately indicates which circuit is affected, streamlining the diagnostic process.

Additionally, fuse blocks often feature a label or color-coding system to further assist with identification. This labeling helps in quickly identifying the correct fuse for a particular circuit, especially in emergency situations. Proper maintenance and regular inspection of the fuse block are essential to ensure the boat's electrical system remains reliable and safe. By understanding the core components and functions of a boat fuse block, boat owners can effectively manage their vessel's electrical needs and promptly address any issues that may arise.

Boat A: What Should Be Done?

You may want to see also

Fuse Types: Different types of fuses used in marine applications and their purposes

Fuses are essential safety devices in marine environments, designed to protect electrical circuits from overcurrent conditions that could lead to damage or hazards. In boats, where electrical systems are critical for navigation, lighting, and engine operation, fuses play a vital role in ensuring safe and reliable performance. Understanding the different types of fuses and their specific purposes is crucial for maintaining a boat's electrical system effectively.

One common type of fuse used in marine applications is the blade fuse. These fuses are typically found in the boat's fuse panel and are designed to protect individual circuits or components. Blade fuses feature a metal blade that melts when excessive current flows through it, interrupting the circuit. They are often used for high-current applications, such as engine starting circuits, where they provide rapid response to overcurrent situations. The blade design allows for easy replacement, ensuring that the boat's electrical system can be quickly restored to normal operation.

Another type of fuse commonly used in marine settings is the cartridge fuse. These fuses are similar to those found in household electrical systems and are often used for lower-current circuits. Cartridge fuses have a cylindrical shape and are inserted into a fuse holder, providing a compact and organized way to manage fuses on a boat. They offer good thermal stability and are suitable for applications where consistent performance is required. Marine engineers often prefer cartridge fuses for their ease of installation and replacement, especially in tight spaces where other fuse types might be less practical.

For high-voltage marine applications, such as those involving large engines or power distribution systems, high-voltage fuses are essential. These fuses are designed to handle significant voltage levels and provide protection against short circuits and overvoltage conditions. High-voltage fuses typically feature a larger glass envelope and specialized internal components to manage the higher electrical stress. They are critical in preventing electrical arcs and potential fires, ensuring the safety of the boat and its occupants.

In addition to these common types, marine electrical systems may also utilize specialized fuses like the time-delay fuse. These fuses have a unique characteristic where they allow a small amount of current to flow for a brief period after a fault is detected, providing a temporary delay. This delay can be crucial in certain applications, such as engine starting, where a brief delay can prevent the fuse from blowing immediately during the initial cranking process. Time-delay fuses are carefully engineered to balance protection and functionality, ensuring that the boat's electrical system operates efficiently while maintaining safety.

Understanding the different types of fuses and their specific purposes is essential for marine engineers and boat owners. By selecting the appropriate fuse for each circuit, potential hazards can be mitigated, and the overall reliability of the boat's electrical system can be significantly improved. Regular maintenance and fuse checks are recommended to ensure that these safety devices function correctly when needed most.

Boat Launch Availability at Pokagon State Park

You may want to see also

Circuit Protection: How fuse blocks safeguard electrical circuits from overcurrent and short circuits

Fuse blocks are essential components in electrical systems, especially in boats, where they play a critical role in circuit protection. These devices are designed to safeguard electrical circuits from potential hazards caused by overcurrent and short circuits. The primary function of a fuse block is to provide a safe and controlled method of interrupting the flow of electricity when an abnormal current level is detected.

In the context of a boat's electrical system, overcurrent can occur due to various reasons, such as faulty wiring, overloaded circuits, or malfunctioning components. When an overcurrent situation arises, the fuse block's internal fuses, typically made of a thin metal wire, melt or break, interrupting the circuit. This rapid response prevents excessive current from causing damage to the wiring, components, or even the boat itself. The key advantage of this design is its ability to self-destruct, ensuring that the rest of the electrical system remains intact.

Short circuits, which occur when there is an unintended path for current flow, can also be effectively managed by fuse blocks. When a short circuit happens, it creates a high-current surge, which is promptly detected by the fuse block. The fuses within the block then interrupt the circuit, effectively isolating the faulted component and preventing potential fires or damage to sensitive electronics. This rapid response is crucial in preventing electrical fires, especially in marine environments where the consequences of an electrical malfunction can be severe.

Fuse blocks are designed with multiple fuses, each protecting a specific circuit or component. This arrangement allows for a more comprehensive protection strategy. If one fuse fails or melts, the others remain intact, ensuring that the electrical system continues to function without complete disruption. This redundancy is vital for maintaining the boat's operational capabilities while still providing robust protection against electrical hazards.

In summary, fuse blocks are indispensable for ensuring the safety and reliability of a boat's electrical system. They offer a simple yet highly effective method of circuit protection, safeguarding against overcurrent and short circuit events. By rapidly interrupting abnormal current flow, these devices prevent potential damage, fires, and system failures, making them a critical component in any marine electrical installation. Understanding their operation and importance is essential for anyone working on a boat's electrical systems.

Tom Selleck's Sailing Passion: Exploring His Love for the Sea

You may want to see also

Boat Electrical Systems: Overview of boat electrical systems and their reliance on fuse blocks

Boat electrical systems have become increasingly sophisticated, with a wide range of electronic devices and accessories now available for modern vessels. These systems rely on a complex network of wiring, fuses, and circuit breakers to ensure safe and efficient operation. At the heart of this network is the fuse block, a critical component that provides protection and organization for the electrical system.

Fuse blocks, also known as circuit breakers or fuse panels, are designed to safeguard the boat's electrical system from potential overloads and short circuits. They are typically mounted in a convenient location, often in the engine compartment or near the main switchboard, providing easy access for maintenance and repairs. Each fuse block contains multiple fuses, each rated for a specific amperage, which is designed to protect a particular circuit or component. When an electrical current exceeds the safe limit, the fuse 'blows', interrupting the circuit and preventing potential damage to the system.

The operation of a boat fuse block is straightforward. When an electrical device is powered on, it draws a certain amount of current. If the device's current draw exceeds the capacity of its fuse, the fuse will melt, breaking the circuit and cutting off power. This prevents the device from overheating or causing a fire hazard. For example, if a high-current-drawing device like a trolling motor is connected to a fuse rated for a lower amperage, the fuse will blow when the motor is engaged, indicating a potential issue with the wiring or the motor itself.

Fuse blocks are designed to be easily replaceable, allowing boat owners to quickly address any issues without extensive electrical work. Each fuse in the block is labeled, making it simple to identify and replace the affected fuse. This feature is crucial for maintaining a safe and efficient electrical system, especially in marine environments where corrosion and moisture can accelerate the deterioration of electrical components.

In summary, boat electrical systems heavily rely on fuse blocks to ensure the safe operation of various electronic devices. These blocks provide a centralized and organized way to manage electrical currents, offering protection against overloads and short circuits. Understanding how fuse blocks work is essential for boat owners and maintenance personnel to effectively maintain and troubleshoot the electrical system, ensuring a reliable and enjoyable boating experience.

Stealth Bay Boat: Is it Worth the Hype?

You may want to see also

Maintenance and Testing: Regular maintenance and testing procedures for optimal fuse block performance

Regular maintenance and testing are crucial aspects of ensuring the proper functioning of a boat's fuse block system. This is especially important for marine environments, where electrical systems are exposed to harsh conditions and potential corrosion. Here's a detailed guide on how to maintain and test your boat's fuse block for optimal performance:

Routine Inspection: Begin by establishing a routine inspection schedule. Aim to inspect the fuse block at least once a month or before and after significant boating trips. During these inspections, visually examine the fuse block for any signs of damage, corrosion, or dislodged connections. Look for melted or burned fuses, which could indicate a previous overload or short circuit. Inspect the block for any physical damage, such as cracks or warping, especially if the boat has been exposed to rough waters or extreme weather conditions.

Cleaning and Corrosion Prevention: Keep the fuse block clean and free of debris. Use a soft brush or cloth to gently remove any dirt or grime that may accumulate. Pay close attention to the fuse terminals and connections, as these areas are prone to corrosion. Clean the terminals with a mild acid-based cleaner or a specialized contact cleaner to remove any corrosion buildup. Ensure that all connections are tight and secure after cleaning. Consider applying a thin layer of dielectric grease to the fuse terminals to prevent corrosion and ensure reliable connections.

Testing Fuses and Circuits: Regularly test the fuses to ensure they are functioning correctly. You can use a multimeter or a dedicated fuse tester for this purpose. Check each fuse for continuity and ensure that it reads a low resistance value when functioning properly. Replace any blown fuses immediately. Additionally, test the circuits connected to the fuse block. This involves measuring the voltage and current at various points in the circuit to ensure they match the expected values.

Load Testing: Conduct load testing to simulate real-world electrical demands on your boat. This is particularly important for high-current circuits, such as those powering engines or large appliances. Gradually increase the load on the fuse block and monitor its performance. Ensure that the fuses do not blow under normal operating conditions. Load testing can help identify potential issues and ensure the fuse block can handle the expected electrical demands of your boat.

Documentation and Record-Keeping: Maintain detailed records of your maintenance and testing activities. Document the date of inspections, the condition of the fuse block, any issues found, and the actions taken to resolve them. Regular record-keeping will help you identify patterns and potential problems over time. It also ensures that you have a comprehensive history of the fuse block's performance, which can be valuable during repairs or when seeking technical support.

By following these maintenance and testing procedures, you can ensure that your boat's fuse block operates reliably and efficiently, minimizing the risk of electrical failures and keeping your vessel safe and functional. Regular care will also extend the lifespan of your fuse block and other electrical components.

The Mystery of Eccentric Boat Ownership Unveiled

You may want to see also

Frequently asked questions

A boat fuse block is a device designed to protect electrical circuits on boats by providing a safe and organized way to manage fuses. It typically consists of a panel or box with multiple fuse slots, allowing boaters to easily replace fuses and protect their electrical systems.

Fuses are an essential safety feature in electrical systems. When an excessive current flows through a circuit, the fuse's wire heats up and melts, interrupting the circuit and preventing potential damage to the boat's electrical components. A fuse block ensures that each circuit has its own dedicated fuse, making it easier to identify and replace faulty fuses.

Absolutely! Boat fuse blocks often accommodate various types of fuses, such as blade fuses, cartridge fuses, and glass fuses. Blade fuses are commonly used and feature a flat, rectangular shape with spring-loaded contacts. Cartridge fuses are similar but have a removable cartridge for easy replacement. Glass fuses are less common but offer high-current capacity and are often used in high-power applications.

Yes, regular maintenance is crucial to ensure the fuse block's reliability. It's recommended to inspect the fuses periodically and replace any blown or damaged fuses promptly. Keep the fuse block clean and dry, as moisture or dirt can affect its performance. Additionally, check for any loose connections and ensure that the fuse block is securely mounted to prevent accidental dislodging during boat operations.