A boat's fuel tank vent system is a crucial component for maintaining the proper air pressure and preventing fuel vapor buildup. This system allows air to enter the tank, which is essential for fuel combustion and overall engine performance. The venting process involves a series of carefully designed components, including a vent valve, a breather filter, and a vent line, all working together to ensure a safe and efficient fuel supply for the vessel's engine. Understanding how these vents function is key to maintaining a boat's engine and ensuring a smooth and safe boating experience.

| Characteristics | Values |

|---|---|

| Vent Type | Pressure relief, vacuum relief, breathers |

| Vent Material | Plastic, metal, rubber |

| Vent Location | Above the fuel tank, at the bottom, or both |

| Vent Size | Varies based on tank capacity and fuel type |

| Vent Function | Prevent fuel vapor buildup, release pressure, allow air intake |

| Vent Design | One-way valve, check valve, or diaphragm |

| Vent Maintenance | Regular cleaning, inspection for damage |

| Vent Safety | Overfill protection, venting during refueling |

| Vent Regulations | Compliance with marine safety standards |

| Vent Customization | Adjustable vents for different fuel levels |

What You'll Learn

- Venting Mechanism: The system uses a small valve to release pressure and prevent fuel tank overflow

- Pressure Relief: Venting allows air to enter the tank, maintaining proper fuel-air ratio

- Boating Safety: Proper venting prevents fuel tank explosions and ensures safe boating

- Fuel Stability: Venting helps maintain fuel quality by preventing fuel degradation

- Engine Performance: Effective venting ensures optimal engine performance by providing fresh air

Venting Mechanism: The system uses a small valve to release pressure and prevent fuel tank overflow

The venting mechanism in a boat's fuel tank is a critical safety feature designed to prevent overflow and ensure the safe operation of the vessel. This system relies on a simple yet effective principle: the use of a small valve that acts as a pressure release point. When the fuel tank is filled, the valve plays a crucial role in maintaining the integrity of the fuel system.

As the fuel tank is refueled, the pressure inside the tank increases due to the accumulation of fuel. This pressure needs to be managed to avoid any potential hazards. The venting mechanism is strategically placed to handle this pressure build-up. It is typically located near the top of the fuel tank, allowing for the release of excess air and vapor. When the tank is full, the valve opens slightly, creating a small opening for the air and vapor to escape. This process ensures that the pressure inside the tank remains within safe limits, preventing any sudden and potentially dangerous expansion.

The valve's design is such that it remains closed when the tank is not being filled, ensuring that the fuel remains contained. However, when the fuel is added, the increasing pressure causes the valve to lift slightly, allowing a controlled release of air and vapor. This controlled release is essential to prevent the formation of a vacuum, which could lead to fuel sloshing and potential spillage. By releasing this pressure, the system maintains a stable environment for the fuel, reducing the risk of overflow and ensuring the boat's fuel system operates efficiently.

In addition to preventing overflow, this venting mechanism also contributes to the overall safety of the boat. By managing the pressure, it minimizes the risk of fuel vapor accumulation, which could ignite if exposed to an ignition source. The controlled release of vapor helps maintain a safe environment within the fuel tank, reducing the chances of dangerous situations arising.

In summary, the venting mechanism's use of a small valve is a vital component in the safe operation of a boat's fuel system. It ensures that the fuel tank remains pressurized without overflowing, contributing to the overall safety and efficiency of the vessel's fuel management. Understanding this basic principle is essential for anyone looking to maintain or operate a boat's fuel system effectively.

Seacock Plug: Bass Boat Essential Maintenance

You may want to see also

Pressure Relief: Venting allows air to enter the tank, maintaining proper fuel-air ratio

Venting in a boat fuel tank is a critical component designed to manage the pressure within the tank and ensure the safe and efficient operation of the vessel. The primary purpose of this system is to maintain a proper fuel-air ratio, which is essential for optimal combustion in the engine. When a boat's engine is running, it requires a precise mixture of fuel and air to function properly. If the fuel-air ratio is off, it can lead to poor performance, reduced power, and even potential engine damage.

The venting system works by allowing air to enter the fuel tank, which helps to regulate the pressure inside. This is particularly important because fuel tanks are often sealed environments, and without proper ventilation, pressure can build up over time. As the engine operates, it consumes fuel, creating a vacuum effect that pulls air into the tank. This air is necessary to maintain the correct fuel-air mixture, especially during high-performance maneuvers or when the engine is under load.

When the engine is idling or not in use, the venting system ensures that the tank remains properly pressurized. This is achieved through a series of vents and valves that allow air to flow in and out of the tank as needed. The vents are typically located at the top of the tank and are designed to open and close automatically based on the pressure inside. When the pressure is low, the vents remain closed, preventing air from entering the tank. However, as the pressure increases, the vents open, allowing air to be drawn into the tank, thus maintaining the required fuel-air ratio.

In addition to pressure relief, venting also helps to prevent the accumulation of volatile compounds in the fuel. Over time, fuel can absorb moisture and other contaminants from the air, leading to potential issues such as phase separation and engine misfires. The venting process helps to expel these volatile compounds, ensuring that the fuel remains stable and ready for use. This is particularly important for boats that are stored for extended periods or are used in varying environmental conditions.

Proper venting is a crucial aspect of boat maintenance, as it directly impacts the engine's performance and longevity. Boat owners should regularly inspect the vents and ensure that they are clear of any debris or obstructions. In some cases, additional vents or specialized venting systems may be required, especially for larger or high-performance vessels. By understanding the role of venting in maintaining the fuel-air ratio, boat owners can take proactive measures to ensure their engines run smoothly and efficiently.

Axopar Boats: Are They Worth the Hype?

You may want to see also

Boating Safety: Proper venting prevents fuel tank explosions and ensures safe boating

Boating safety is of utmost importance, especially when it comes to preventing accidents and ensuring the well-being of everyone on board. One critical aspect often overlooked is the proper venting of fuel tanks in boats. While it might seem like a minor detail, inadequate venting can lead to dangerous consequences, including fuel tank explosions. Understanding how fuel tank vents work and implementing the right practices can significantly contribute to a safer boating experience.

Fuel tanks in boats are designed to store gasoline or diesel, and these tanks are typically located in compartments that are sealed to prevent fuel evaporation and leakage. Over time, however, fuel tanks can experience pressure build-up due to several factors. Firstly, the expansion and contraction of fuel with temperature changes can create pressure. Secondly, the act of refueling the boat introduces additional pressure, especially if the process is not done carefully. If this pressure is not released, it can lead to a dangerous situation.

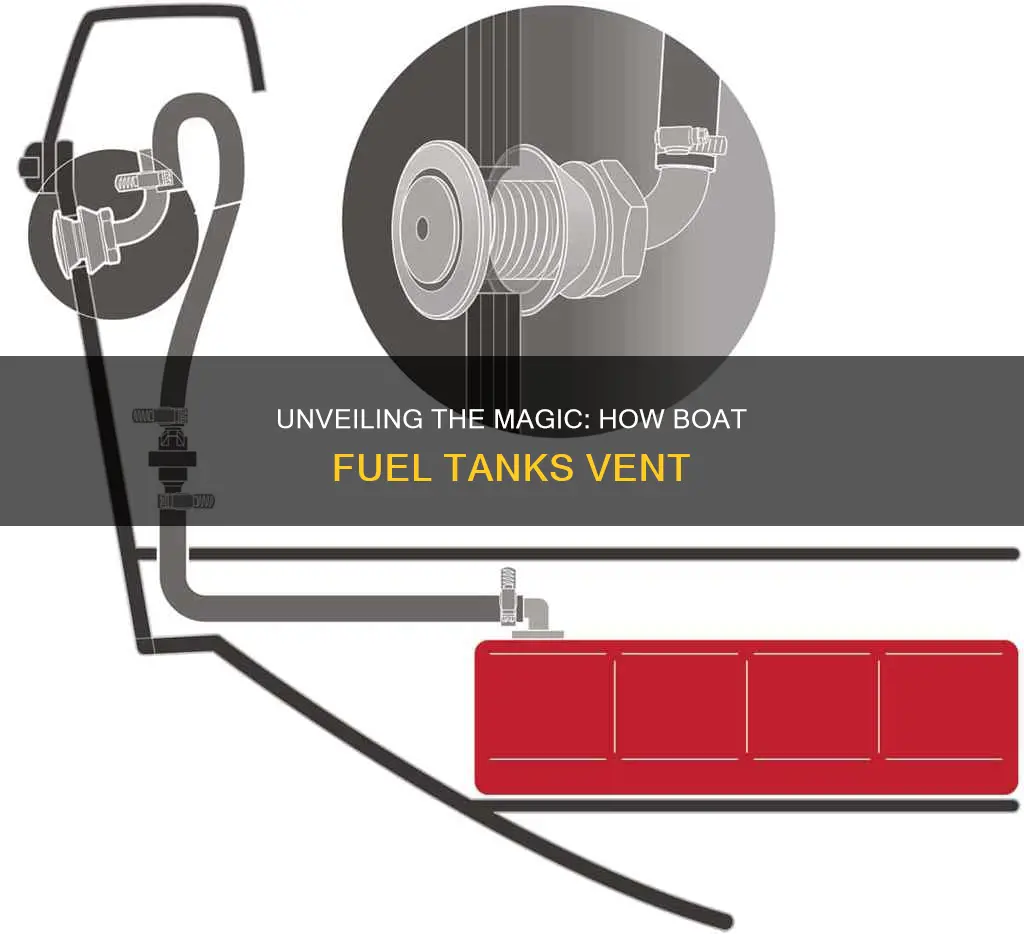

Venting is the process of allowing air to enter the fuel tank and escape, which helps regulate the pressure inside. This is achieved through a series of carefully designed components. At the heart of the venting system is a vent valve, which is often located near the fuel tank. This valve is designed to open and close automatically, allowing air to pass through when needed. When the fuel tank is full and the pressure is stable, the valve remains closed, ensuring that no air enters the system. However, as the fuel expands or contracts, the pressure changes, causing the valve to open and release the excess air.

The venting system also includes a breather tube, which is connected to the fuel tank and extends above the waterline. This tube acts as a passage for air to enter the tank and is designed to prevent water from entering the system. When the fuel tank is full, the breather tube is submerged, and the fuel level is above it, ensuring a tight seal. As the fuel level drops, the breather tube rises, allowing air to enter and equalize the pressure. This simple yet effective mechanism is crucial in preventing fuel tank explosions.

In addition to the physical components, proper maintenance and awareness are essential. Regularly inspecting the vent valves and breather tubes for any signs of damage or blockage is vital. Over time, debris or contaminants might accumulate, hindering the venting process. Boat owners should also be mindful of the fuel's condition and ensure that it is stored and handled correctly to minimize the risk of pressure build-up. By following these guidelines, boaters can significantly reduce the chances of fuel tank explosions and enjoy a safer boating experience.

The Boat Named by Marlow: A Detailed Exploration

You may want to see also

Fuel Stability: Venting helps maintain fuel quality by preventing fuel degradation

Venting in a boat's fuel tank system is a critical component designed to ensure the stability and longevity of the fuel, which is essential for safe and efficient operation. The primary purpose of this venting mechanism is to maintain the quality of the fuel by preventing degradation, which can occur due to various factors such as heat, pressure, and the presence of contaminants.

When a boat's engine is not in use, the fuel tank can experience a buildup of gases, primarily carbon dioxide and water vapor, due to the natural processes of evaporation and condensation. These gases can exert pressure on the fuel, leading to potential issues. One of the key functions of the vent is to release these gases, allowing for a controlled environment within the tank. This controlled release of gases helps to prevent the formation of a vacuum, which could cause fuel to vaporize and potentially enter the engine's intake system, leading to performance issues.

The venting system typically consists of a series of components, including a vent valve, a breather pipe, and a vent fitting. The vent valve is designed to open and close automatically, allowing gas to escape when necessary. This valve is often connected to the breather pipe, which acts as a conduit for the gases to travel from the tank to the atmosphere. The vent fitting, usually located near the top of the fuel tank, provides a secure and sealed connection for the breather pipe.

As the boat's engine operates, the fuel tank vents play a crucial role in maintaining a stable fuel-air mixture. When the engine is running, the combustion process generates heat, which can cause the fuel to expand and generate additional gases. The venting system allows these gases to escape, preventing a buildup of pressure that could lead to fuel degradation. This is particularly important as it helps to maintain the fuel's octane level, ensuring optimal engine performance and preventing issues like engine knock or pre-ignition.

In addition to gas release, the venting system also contributes to fuel stability by minimizing the introduction of contaminants. Over time, water and other impurities can accumulate in the fuel tank, especially in marine environments where condensation is common. The venting mechanism allows for the release of these contaminants, keeping the fuel clean and free from degradation-causing agents. This is vital for the long-term health of the fuel system and the overall performance of the boat's engine.

Helm Seat for Boats: Understanding the Captain's Chair

You may want to see also

Engine Performance: Effective venting ensures optimal engine performance by providing fresh air

Effective venting is a critical aspect of maintaining optimal engine performance in boats, especially when it comes to fuel tanks. Proper ventilation ensures that the engine receives the necessary fresh air for efficient combustion, which directly impacts the overall power and efficiency of the vessel. Here's a detailed look at how this process works and why it's essential.

In a boat's fuel system, the tank is typically designed with a venting mechanism to allow air to enter and exit. This is crucial because fuel, especially when it's in a liquid state, needs to be in a well-ventilated environment to prevent issues like vapor lock and engine misfires. When a boat's engine is running, the fuel tank is constantly being filled and emptied, creating a dynamic environment. The venting system acts as a pathway for air to enter the tank, replacing the fuel that is being used, and also allowing any built-up pressure to escape.

The primary function of this venting process is to provide fresh air to the engine's intake system. As the engine operates, it creates a vacuum, pulling air through the intake manifold. If this air is not fresh, it can lead to a variety of problems. For instance, if the air is rich in fuel vapor, it can cause the engine to run too rich, leading to reduced power and potential engine damage. Conversely, if the air is too lean, it can result in a condition known as "runout," where the engine struggles to maintain a stable running condition.

To ensure optimal engine performance, the venting system must be designed to provide a steady supply of fresh air. This is typically achieved through a combination of a venturi (a device that increases air pressure and flow) and a breather element. The venturi creates a low-pressure area, drawing fresh air into the system, while the breather element filters out any contaminants, ensuring that only clean air enters the engine. This setup guarantees that the engine always has the right air-fuel mixture, optimizing power output and fuel efficiency.

In summary, effective venting in a boat's fuel tank is a vital process that directly influences engine performance. By providing a continuous supply of fresh air, it ensures the engine operates at its peak, delivering the power and efficiency that boaters rely on. Understanding and maintaining this system is essential for any boat owner to ensure a smooth and reliable journey on the water.

Houston Boat Show: Know Before You Go

You may want to see also

Frequently asked questions

A vent in a boat fuel tank serves multiple purposes. Firstly, it allows air to enter the tank as fuel is consumed, preventing a vacuum that could cause fuel to flow back into the engine when starting. Secondly, it releases excess pressure built up inside the tank due to temperature changes or fuel expansion, ensuring the tank's integrity and preventing damage.

The venting system typically consists of a small opening or a dedicated vent line that connects the fuel tank to the atmosphere or a separate vent chamber. When the engine is running, fuel is drawn into the engine, creating a partial vacuum in the tank. The vent allows air to flow into the tank, replacing the expelled fuel and maintaining a balanced pressure.

Yes, it is possible for a vent to become clogged or blocked over time. This can happen due to the accumulation of dirt, debris, or even algae, especially in marine environments. Clogging can lead to reduced air flow, causing issues like fuel starvation, engine misfires, or difficulty starting the engine. Regular maintenance and cleaning of the vent system are essential to prevent this.

Some common problems associated with boat fuel tank vents include:

- Clogging: As mentioned, debris can block vents, requiring cleaning or replacement.

- Leaks: Vents may develop leaks if they are damaged or improperly installed, leading to fuel loss and potential safety hazards.

- Malfunctioning vent valves: These can fail to open or close properly, affecting the engine's performance.

To maintain proper vent functionality:

- Regularly inspect the vents for any signs of damage, corrosion, or blockages.

- Keep the fuel tank clean and free of contaminants.

- Check for any fuel leaks around the vent connections.

- Consider using a fuel stabilizer to prevent fuel degradation, which can indirectly help maintain vent performance.