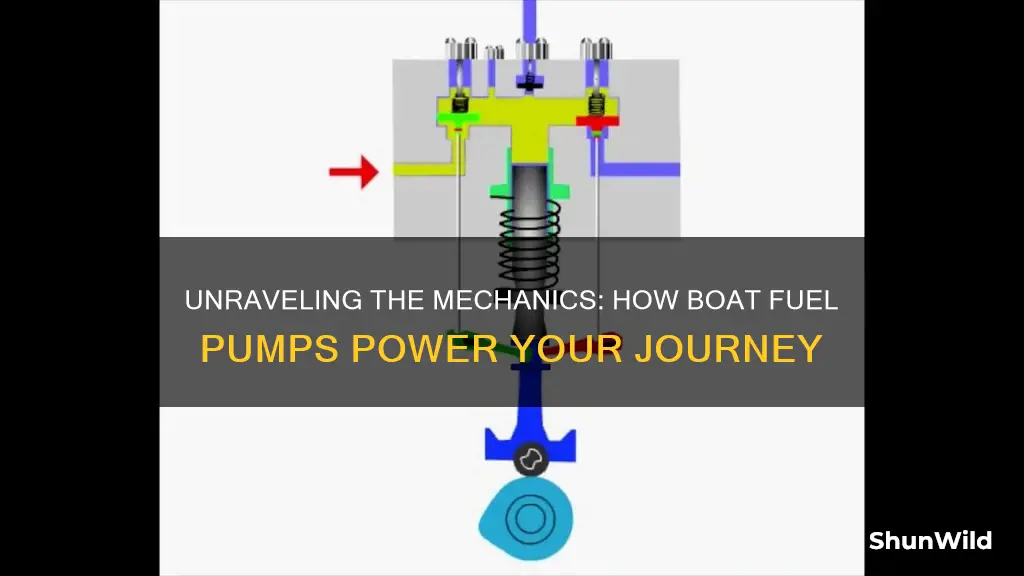

A boat fuel pump is a critical component in the fuel system of any vessel, ensuring a steady and efficient supply of fuel to the engine. It operates by drawing fuel from the tank and forcing it through a series of filters and lines to the engine, where it is ignited to power the boat. The pump's mechanism typically involves a diaphragm or a gear system that creates suction or pressure to move the fuel, and it can be electric or mechanical, depending on the boat's design. Understanding how this system works is essential for maintaining the boat's performance and ensuring safe and efficient operation.

What You'll Learn

- Engine Operation: The pump delivers fuel from the tank to the engine's carburetor or injectors

- Pressure Regulation: It maintains optimal pressure to ensure efficient combustion

- Fuel Filtration: The pump passes through a filter to prevent contamination

- Fuel Injection: In modern boats, the pump directly injects fuel into the engine's cylinders

- Engine Performance: Proper pump function is crucial for optimal engine power and efficiency

Engine Operation: The pump delivers fuel from the tank to the engine's carburetor or injectors

The engine operation of a boat fuel pump is a critical component in the power system of a vessel, ensuring a steady supply of fuel to the engines. When the engine is started, the fuel pump is activated, and its primary function is to deliver fuel from the storage tank to the engine's carburetor or fuel injectors. This process is essential for the engine to operate efficiently and produce the necessary power for the boat's propulsion.

The pump operates based on the principle of creating a vacuum or low-pressure area in the fuel line, which draws fuel from the tank. This is typically achieved through a mechanical or electric pump mechanism. When the engine is running, the pump is designed to maintain a consistent fuel flow rate, ensuring that the engine receives the required amount of fuel for optimal performance. The pump's efficiency is crucial as it directly impacts the engine's power output and overall reliability.

In the case of a carburetor-equipped engine, the pump delivers fuel to the carburetor, where it mixes with air and is then drawn into the engine's cylinders. The carburetor acts as a regulator, adjusting the fuel-air mixture based on engine speed and load. This process is a delicate balance, as too much or too little fuel can lead to poor engine performance or even damage.

For fuel-injected engines, the pump's role is slightly different. Here, the pump delivers fuel directly to the injectors, which are strategically positioned in the engine's intake manifold. The injectors precisely meter the fuel, ensuring a consistent and accurate fuel-air mixture. This system provides better control over the engine's performance, allowing for more efficient combustion and reduced emissions.

The pump's operation is often controlled by the engine's management system, which monitors various parameters such as engine speed, temperature, and load. This control system adjusts the pump's output to maintain the ideal fuel-air mixture, optimizing the engine's performance. Proper maintenance and regular checks of the fuel pump are essential to ensure its longevity and the overall reliability of the boat's engine system.

Opening the Boat Shop in Twilight Princess: A Guide

You may want to see also

Pressure Regulation: It maintains optimal pressure to ensure efficient combustion

The fuel pump in a boat is a critical component that ensures a steady supply of fuel to the engine, enabling efficient combustion and optimal performance. One of the key functions of this pump is pressure regulation, which plays a vital role in maintaining the right fuel pressure for efficient combustion.

Pressure regulation is essential because it ensures that the fuel is delivered to the engine at the correct pressure. In marine applications, the fuel pump must provide a consistent and regulated pressure to facilitate the mixing of fuel and air, which is crucial for the combustion process. If the pressure is too low, the engine may not receive enough fuel, leading to poor performance and potential stalling. Conversely, excessive pressure can cause fuel to atomize too finely, leading to inefficient combustion and increased emissions.

The pump achieves pressure regulation through a combination of design features and control mechanisms. One common method is the use of a pressure-regulating valve or a pressure-compensated pump. These devices are designed to maintain a specific pressure level by adjusting the flow rate of fuel based on engine load and speed. When the engine demands more power, the pump increases the pressure to supply a higher volume of fuel, ensuring that the engine receives the required amount for efficient combustion.

Additionally, some fuel pumps incorporate a pressure-sensing system that monitors the fuel pressure in real-time. This system can automatically adjust the pump's performance to maintain the desired pressure. For instance, if the pressure drops due to a clogged fuel line or a faulty fuel filter, the pump can compensate by increasing its output to restore the optimal pressure. This dynamic regulation ensures that the engine always operates within the ideal fuel pressure range.

By precisely controlling the fuel pressure, the pump contributes to the overall efficiency and performance of the boat's engine. Proper pressure regulation prevents fuel wastage, reduces emissions, and ensures that the engine operates smoothly and reliably, even in varying conditions. This is particularly important for marine applications where engines may be exposed to different environmental factors and load demands.

Painting a Metal Boat: The Ultimate Guide to Success

You may want to see also

Fuel Filtration: The pump passes through a filter to prevent contamination

The fuel filtration system is a critical component in ensuring the efficient and safe operation of a boat's fuel pump. When a boat's engine requires fuel, the pump is responsible for drawing it from the tank and delivering it to the engine. However, the fuel can contain impurities and contaminants that can cause significant issues if left unchecked. This is where the filtration process comes into play.

The fuel pump is designed to draw fuel from the tank and pass it through a filter. This filter is typically located in close proximity to the pump, often integrated into the pump's design or mounted nearby. The primary function of this filter is to capture and remove any solid particles, water, and other contaminants that may be present in the fuel. Over time, fuel can absorb moisture, leading to the formation of condensation, which can cause corrosion and damage to the engine. The filter also prevents the entry of water, which can lead to engine misfires, reduced performance, and even catastrophic failure.

As the fuel passes through the filter, it is subjected to a series of processes that ensure its purity. The filter media, often a fine mesh or a series of screens, traps any solid particles, such as dirt, rust, or debris, that may be present in the fuel. This is crucial as these particles can cause mechanical damage to the engine's internal components, leading to expensive repairs or replacements. Additionally, the filter also helps to remove any water droplets that may have accumulated in the fuel, ensuring that the engine receives only clean, dry fuel.

Modern boats often employ advanced fuel filtration systems that utilize multiple stages of filtration. This multi-stage approach ensures a higher level of purity in the fuel. The initial stage might involve a mechanical filter to capture larger particles, followed by a finer filter to remove smaller contaminants. Some systems even incorporate electronic sensors to monitor the fuel's quality, alerting the operator if contamination levels are excessive.

In summary, fuel filtration is an essential process in the operation of a boat's fuel pump. By passing the fuel through a filter, the system ensures that only clean, dry fuel reaches the engine, preventing contamination and potential damage. This simple yet effective mechanism is a vital part of boat maintenance, contributing to the overall reliability and longevity of the vessel's propulsion system.

Stingray 180RX: A Boat Worth Buying?

You may want to see also

Fuel Injection: In modern boats, the pump directly injects fuel into the engine's cylinders

In modern boats, fuel injection systems have revolutionized the way engines operate, offering improved performance, efficiency, and control. At the heart of this system is the fuel pump, a critical component that ensures a precise and continuous supply of fuel to the engine. This pump plays a vital role in the combustion process, where it directly injects fuel into the engine's cylinders, replacing the traditional carburetor setup.

The fuel pump in a modern boat is typically an electric or mechanical device, often located near the engine or in a fuel tank. Its primary function is to draw fuel from the tank and deliver it under pressure to the engine's fuel injectors. This process ensures that the fuel is atomized and mixed with air in the correct ratio before being injected into the cylinders. The pump's operation is highly regulated to maintain optimal engine performance and efficiency.

When the engine is started, the fuel pump activates, drawing fuel from the tank and increasing its pressure to a precise level. This pressure is carefully controlled to ensure that the fuel is delivered at the right time and in the correct amount for each cylinder. The pump's operation is synchronized with the engine's ignition system, ensuring that fuel injection occurs simultaneously with the combustion process. This timing is crucial for efficient engine operation and optimal power output.

The fuel pump's design incorporates various features to ensure reliability and performance. These include pressure regulators, filters, and check valves, which help maintain the desired fuel pressure, remove contaminants, and prevent fuel backflow. Additionally, some pumps have built-in pressure gauges, allowing operators to monitor the fuel pressure and make adjustments if necessary. This level of control and precision is essential for modern boat engines, which demand high performance and responsiveness.

In summary, the fuel pump in a modern boat is a sophisticated component that plays a critical role in the fuel injection process. It ensures a precise and continuous supply of fuel to the engine, replacing the traditional carburetor system. With its ability to deliver fuel under pressure and maintain optimal engine performance, the fuel pump is a key enabler of efficient and powerful boat operation. Understanding its function and maintenance requirements is essential for boat owners to ensure their vessels perform at their best.

Guide to Checking Boat Rockerz Battery Health

You may want to see also

Engine Performance: Proper pump function is crucial for optimal engine power and efficiency

The fuel pump in a boat's engine system plays a critical role in ensuring optimal engine performance and efficiency. Proper pump function is essential to deliver the required amount of fuel to the engine at the right pressure, which directly impacts power output and overall engine health. When the pump operates efficiently, it ensures a consistent and reliable fuel supply, allowing the engine to run smoothly and deliver its full potential.

Engine power is directly related to the amount of fuel available to the combustion process. A well-functioning pump ensures that the engine receives the precise fuel-air mixture needed for efficient combustion. This results in increased power output and improved engine response, especially during acceleration or when demanding more power from the engine. Efficient pump operation also contributes to better fuel economy, as the engine can operate at its most efficient levels with the right fuel supply.

The pump's role becomes even more critical in high-performance boats or those with larger engines. These applications require a higher volume of fuel to be delivered at increased pressure to meet the engine's demands. A properly functioning pump can handle these requirements, ensuring that the engine receives the necessary fuel to maintain optimal performance even under heavy load conditions. This is particularly important during racing or when the boat is pushed to its performance limits.

In addition to power and efficiency, proper pump function also contributes to engine longevity. When the pump works as intended, it helps prevent issues like fuel starvation, which can lead to engine damage over time. It also reduces the risk of fuel-related problems such as engine misfires, reduced performance, and even engine failure. By maintaining a consistent fuel supply, the pump ensures that the engine operates within its optimal parameters, promoting longer engine life and reducing the need for costly repairs.

In summary, the fuel pump's proper function is vital for achieving and maintaining optimal engine performance in boats. It ensures the engine receives the right amount of fuel at the correct pressure, resulting in increased power, improved efficiency, and better overall engine health. Boat owners and operators should regularly inspect and maintain their fuel pumps to guarantee reliable performance and maximize the potential of their engines.

Boat Radar Range: How Far Can It Reach?

You may want to see also

Frequently asked questions

A boat fuel pump is a vital component in the fuel system of a vessel, ensuring a continuous and efficient supply of fuel to the engine. It operates by creating a vacuum or pressure to move fuel from the tank to the engine, where it is ignited to power the boat. The pump is typically driven by the engine's crankshaft or a separate electric motor, and it can be either a manual or automatic device.

Manual fuel pumps are activated by a manual override, often a lever or switch, which allows the operator to control the fuel flow. These are commonly used in smaller boats or as a backup system. Automatic fuel pumps, on the other hand, are self-regulating and adjust their operation based on engine speed and load. They are more common in larger boats and provide a more efficient and reliable fuel supply.

Regular maintenance is crucial to ensure the longevity of your fuel pump. Signs that your pump may require attention include fuel starvation, where the engine cuts out or runs poorly, especially during high-load conditions. Another indicator is fuel leaks or contamination, which can be caused by a faulty pump or gasket. Additionally, unusual noises from the pump or engine, such as hissing or knocking, could suggest a problem.

While some boat owners with mechanical knowledge might attempt a fuel pump replacement, it is generally recommended to seek professional assistance. Fuel pumps are complex components, and improper installation can lead to fuel leaks, engine damage, or other issues. Professionals have the expertise and tools to ensure a proper fit and function, and they can also identify any underlying causes for the pump's failure.