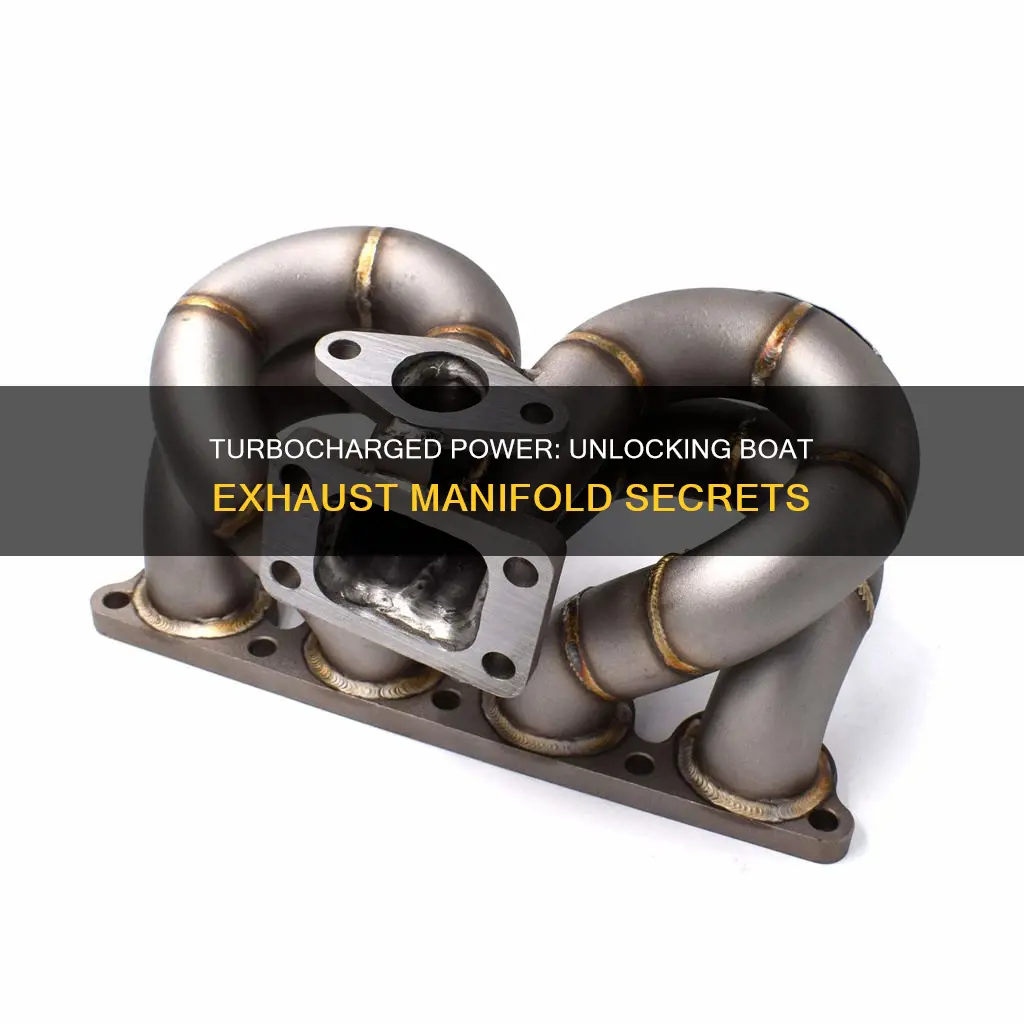

A boat exhaust manifold plays a crucial role in the performance and efficiency of a turbocharged engine. When a boat is equipped with a turbocharger, the exhaust manifold is designed to efficiently route exhaust gases from the engine's cylinders to the turbocharger. The manifold acts as a collector, gathering exhaust from multiple cylinders and directing it towards the turbo's inlet. This process increases engine power by forcing more air into the combustion chamber, which is then accelerated through the exhaust manifold, creating a high-pressure environment. The manifold's design is critical to ensure optimal performance, as it must manage the flow of exhaust gases efficiently, preventing backpressure and maximizing the turbo's potential. Understanding the intricate relationship between the exhaust manifold and turbocharger is essential for optimizing a boat's engine performance and maintaining its longevity.

| Characteristics | Values |

|---|---|

| Exhaust Manifold Design | A boat exhaust manifold with a turbocharger typically consists of a series of passages or ports that direct exhaust gases from multiple cylinders to a single collector pipe. This design allows for efficient gas flow and scavenging. |

| Turbocharger Placement | The turbocharger is usually positioned in the exhaust stream, either in the exhaust manifold or downstream of it. This placement ensures that the turbocharger can extract energy from the exhaust gases. |

| Boost Control | The exhaust manifold helps regulate the boost pressure by controlling the flow rate of exhaust gases. This is crucial for maintaining optimal engine performance and preventing overboost. |

| Noise and Vibration | Proper exhaust manifold design can reduce engine noise and vibration, especially when combined with a well-designed turbo system. |

| Engine Efficiency | By utilizing the energy in exhaust gases, a turbo system with an efficient exhaust manifold can improve engine power output and overall efficiency. |

| Material Considerations | Materials like stainless steel or aluminum are commonly used for boat exhaust manifolds due to their durability and resistance to corrosion, ensuring longevity in marine environments. |

| Emission Control | Modern exhaust manifolds often incorporate catalysts or other emission control devices to reduce harmful pollutants, meeting environmental regulations. |

| Engine Size and Power | The exhaust manifold design may vary based on engine size and power output, requiring customization for different marine applications. |

| Maintenance and Serviceability | Easy access to the exhaust manifold is essential for maintenance, allowing for regular servicing and potential upgrades. |

What You'll Learn

Turbocharged Engine: Exhaust Manifold Design

A turbocharger is a vital component in modern engines, especially those with a focus on performance and efficiency. When a boat engine is equipped with a turbo, the exhaust manifold plays a critical role in optimizing the engine's performance. The exhaust manifold is a crucial part of the exhaust system, responsible for collecting exhaust gases from the engine's cylinders and directing them into the turbocharger. This process is essential for the turbo to function effectively, as it requires a steady and controlled flow of exhaust gases to spin the turbine and generate boost.

In the context of a boat engine, the exhaust manifold design must consider the unique challenges of marine environments. Marine applications often require a robust and durable design due to the harsh operating conditions, including exposure to saltwater and varying temperatures. The manifold must be constructed using materials that can withstand corrosion and provide excellent heat dissipation to manage the high temperatures generated during operation.

The design of the exhaust manifold for a turbocharged boat engine involves several key considerations. Firstly, the manifold should have an efficient layout to ensure a smooth and rapid flow of exhaust gases. This is crucial for maintaining turbo response and preventing backpressure, which can negatively impact engine performance. The manifold's shape and size should be optimized to direct the gases towards the turbocharger efficiently, ensuring a steady supply of energy to drive the turbine.

Secondly, the manifold's construction materials are critical. Marine environments demand materials that are resistant to corrosion and can handle the extreme temperatures associated with turbocharged engines. Common materials include stainless steel and heat-resistant alloys, which provide durability and longevity. The manifold's surface finish is also important; a smooth finish minimizes turbulence and ensures a clean flow of exhaust gases, further enhancing performance.

Additionally, the exhaust manifold should incorporate features to manage noise and vibration. Turbocharged engines can produce significant noise, and the manifold design can include baffles or silencing materials to reduce exhaust noise. Proper vibration dampening is also essential to prevent excessive engine vibration, ensuring a smooth and reliable operation.

In summary, the exhaust manifold design for a turbocharged boat engine requires careful consideration of flow efficiency, material selection, and noise/vibration management. By optimizing these aspects, engineers can create a manifold that effectively channels exhaust gases to the turbocharger, resulting in improved engine performance and a more responsive and efficient marine powerplant.

Unraveling the Mystery: How Boat Zincs Protect Your Vessel

You may want to see also

Boost Pressure Regulation: Manifold's Role

The exhaust manifold plays a crucial role in managing boost pressure in a turbocharged engine system, especially in boats where space and weight are often limited. When a boat is equipped with a turbocharger, the exhaust manifold's design becomes even more critical to ensure optimal performance and efficiency. Here's an overview of its function in boost pressure regulation:

In a turbocharged engine, the turbocharger acts as a forced induction device, compressing the incoming air to create more power. This process generates a significant amount of boost pressure, which needs to be carefully controlled to prevent engine damage and ensure efficient power delivery. The exhaust manifold is the first component in this process, acting as a collector for exhaust gases from the engine cylinders. It is designed to efficiently route these gases to the turbocharger, where the energy is harnessed.

The manifold's primary role in boost pressure regulation is to provide a controlled environment for the exhaust gases to interact with the turbocharger. It does this by ensuring a consistent and steady flow of gases, which is crucial for maintaining a stable boost pressure. The manifold's design includes a series of passages and outlets that direct the exhaust gases at specific angles and velocities, optimizing the energy transfer to the turbocharger. This controlled flow helps in preventing surge or vacuum conditions that could lead to unstable boost pressure.

Additionally, the exhaust manifold's material and construction play a vital role in managing heat. Turbochargers operate at high temperatures, and the manifold must be able to withstand these extreme conditions without compromising its structural integrity. Materials like stainless steel or heat-resistant alloys are commonly used to ensure durability and longevity, especially in marine environments where corrosion resistance is essential.

By effectively managing the flow and temperature of exhaust gases, the exhaust manifold contributes to the overall performance and reliability of the turbocharged boat engine. It ensures that the turbocharger operates within its optimal range, providing the desired boost pressure without causing any damage to the engine or associated components. Proper design and maintenance of the exhaust manifold are key to achieving efficient power output and a smooth, responsive driving experience.

Black Stallion's Boat: Lost at Sea

You may want to see also

Turbocharged Engine Efficiency: Exhaust Manifold Impact

The exhaust manifold plays a crucial role in optimizing the performance of a turbocharged engine, especially in the context of boats. When a boat is equipped with a turbocharger, the exhaust manifold becomes a critical component in managing the flow of exhaust gases and ensuring efficient power delivery. Here's an overview of its impact:

In a turbocharged engine, the exhaust manifold is designed to efficiently collect and combine exhaust gases from multiple cylinders. This is particularly important in boats, where multiple cylinders are often arranged in a V-shape or in-line configuration. The manifold acts as a collector, directing the exhaust gases from each cylinder into a single, centralized pipe. This design allows for a more streamlined flow, reducing back pressure and ensuring that the turbocharger receives a consistent and efficient stream of gases. By properly managing the exhaust flow, the manifold helps maintain optimal engine performance and responsiveness.

The impact of the exhaust manifold on turbo engine efficiency is twofold. Firstly, it ensures a more uniform exhaust gas velocity, which is essential for efficient turbocharger operation. Turbochargers rely on the energy of the exhaust gases to spin their compressor, and a well-designed manifold helps maintain this velocity, maximizing the turbo's performance. Secondly, the manifold's design can influence the engine's overall efficiency. A properly engineered manifold minimizes turbulence and restricts the flow, allowing for better control over the exhaust pressure and temperature, which are critical factors in engine performance.

In the context of boats, where space and weight are often limited, the exhaust manifold's design becomes even more critical. A well-designed manifold can help reduce the overall system size and weight, contributing to better handling and fuel efficiency. Additionally, it ensures that the exhaust gases are directed away from the boat's occupants and sensitive areas, maintaining a safe and comfortable environment.

Furthermore, the exhaust manifold's impact extends to noise reduction. By optimizing the flow and minimizing turbulence, the manifold can help reduce engine noise, which is particularly important for recreational boats where passenger comfort is a priority. This aspect is often overlooked but is essential for a pleasant boating experience.

In summary, the exhaust manifold is a vital component in the overall efficiency and performance of a turbocharged boat engine. Its design and functionality directly influence the engine's ability to harness the power of turbochargers, ensuring optimal exhaust flow, engine responsiveness, and overall system efficiency. Understanding and optimizing the exhaust manifold's role can lead to significant improvements in boat engine performance and reliability.

Mastering the Art of Docking: Putting Your Boat in a Slip

You may want to see also

Turbocharged Engine Performance: Manifold's Influence

The exhaust manifold plays a crucial role in optimizing the performance of a turbocharged engine, especially in marine applications. When a boat engine is equipped with a turbocharger, the exhaust manifold becomes a critical component in managing the flow of exhaust gases and ensuring efficient power delivery. Here's an overview of its influence:

In a turbocharged engine, the exhaust manifold's primary function is to collect exhaust gases from multiple cylinders and route them towards the turbocharger. This process is essential because it allows for the rapid expulsion of gases, which is vital for maintaining engine efficiency and performance. The manifold acts as a collector, ensuring that exhaust from all cylinders is directed efficiently, preventing any backpressure that could hinder engine response. This is particularly important in boats, where space is limited, and proper exhaust management is critical for overall engine health.

The design of the exhaust manifold is key to its effectiveness. It typically consists of a series of passages or channels that are carefully engineered to control the flow of gases. These passages are often designed with specific angles and lengths to optimize the velocity and direction of exhaust flow. By carefully managing the exhaust gas flow, the manifold helps to maintain a steady and efficient power output from the turbocharger. This is crucial, as turbochargers rely on the energy of the exhaust gases to spin their turbine, which then increases the engine's power output.

One of the critical aspects of the exhaust manifold's design is its ability to minimize backpressure. Backpressure occurs when exhaust gases are unable to flow freely, causing a buildup of pressure. This can lead to reduced engine performance and even potential damage to the turbocharger. A well-designed manifold ensures that exhaust gases are directed efficiently, reducing backpressure and allowing for optimal turbocharger operation. This is especially important in high-performance marine applications where engines need to respond quickly and efficiently.

Furthermore, the exhaust manifold's influence extends to noise reduction. Turbocharged engines can produce significant noise due to the rapid expulsion of exhaust gases. The manifold's design can help mitigate this by controlling the flow and directing the gases in a way that reduces noise levels. This is an essential consideration for boat owners, as excessive noise can be a nuisance and may even be regulated in certain areas.

In summary, the exhaust manifold is a critical component in the performance of a turbocharged boat engine. Its design and functionality directly impact the efficiency, power output, and overall health of the engine. By managing exhaust gas flow, minimizing backpressure, and potentially reducing noise, the manifold ensures that the turbocharger operates optimally, delivering the required power while maintaining the engine's longevity. Understanding and optimizing the exhaust manifold's design is essential for marine engineers and enthusiasts to fully harness the benefits of turbocharged engines.

Running Lights: Boat Bulb Replacement Guide

You may want to see also

Turbocharged Engine Maintenance: Exhaust Manifold Care

The exhaust manifold is a critical component in any turbocharged engine setup, especially for boats, where space and weight are often limited. It serves as a collector for exhaust gases from the engine's cylinders, directing them into the turbocharger for efficient power generation. When a boat engine is turbocharged, the exhaust manifold's role becomes even more crucial as it needs to handle the increased pressure and volume of exhaust gases while ensuring optimal performance and longevity.

In the context of boat engines, the exhaust manifold is typically designed to be compact and lightweight, considering the space constraints. It is often made of durable materials such as stainless steel or aluminum to withstand the high temperatures and pressures involved. The manifold's design includes a series of passages or channels that are carefully engineered to match the engine's cylinder layout and ensure even gas distribution. This even distribution is vital to prevent hotspots and maintain consistent turbo performance.

Proper maintenance of the exhaust manifold is essential to keep the turbocharged boat engine running efficiently. Over time, the manifold can accumulate deposits and carbon buildup, especially in the tighter spaces of a boat engine. These deposits can restrict exhaust flow, leading to reduced power and potential performance issues. Regular cleaning and inspection are recommended to prevent such problems. Cleaning can be done using specialized tools and chemicals designed for exhaust systems, ensuring that no damage occurs to the manifold's delicate passages.

Another critical aspect of exhaust manifold care is monitoring for any signs of damage or wear. High-temperature environments and the pressure of exhaust gases can cause the manifold to degrade over time. Look for any cracks, warping, or blockages that may have occurred. In the event of damage, it is crucial to replace the exhaust manifold promptly to avoid further complications. Proper installation and regular checks can help ensure the manifold's longevity and the overall health of the turbocharged engine.

Additionally, when performing maintenance, it is essential to consider the overall exhaust system. The exhaust manifold connects to the turbocharger and the catalytic converter, and any issues with these components can impact the manifold's performance. Regular servicing of the entire exhaust system is recommended to identify and address potential problems early on. By taking a comprehensive approach to maintenance, boat owners can ensure their turbocharged engines operate at peak efficiency while extending the life of the exhaust manifold and associated components.

Preventing Aluminum Boat Oxidation: Protection and Maintenance

You may want to see also

Frequently asked questions

The exhaust manifold is a crucial component in a boat engine with a turbo system. It is responsible for collecting exhaust gases from multiple cylinders and directing them into the turbocharger. The manifold is typically made of heat-resistant materials to withstand the high temperatures of the exhaust gases. It has a series of passages or ports that are strategically designed to optimize gas flow, ensuring efficient exhaust scavenging and turbocharger performance.

In a turbo-charged boat engine, the exhaust manifold plays a vital role in the overall performance and efficiency. It acts as a collector, merging the exhaust streams from each cylinder into a single, high-pressure stream. This combined flow is then directed towards the turbocharger, which extracts energy from the exhaust gases to spin the compressor, thereby increasing power output. The manifold's design and construction are critical to maintaining proper gas flow and preventing backpressure, ensuring the turbocharger operates efficiently.

Absolutely! An exhaust manifold in a boat engine with a turbo offers several advantages. Firstly, it improves engine performance by efficiently routing exhaust gases to the turbocharger, resulting in increased power and torque. Secondly, it helps in maintaining a consistent exhaust flow, which is essential for stable turbo operation. Additionally, a well-designed manifold can reduce exhaust backpressure, allowing for better engine response and fuel efficiency. This component is a key factor in optimizing the performance of a boat engine equipped with a turbocharger.