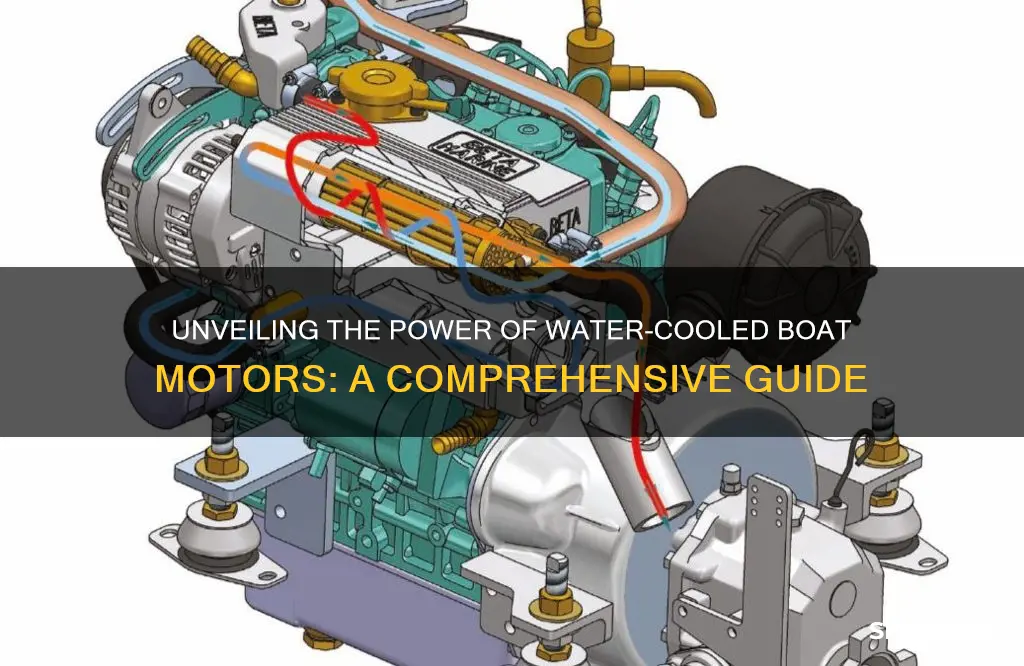

Water-cooled boat motors are a popular choice for marine applications due to their efficient cooling system, which helps maintain optimal engine performance even under high loads. This technology involves circulating coolant through the engine block, absorbing heat from the engine components, and then transferring it to the water, which is typically discharged overboard. The process ensures that the engine operates at a stable temperature, preventing overheating and potential damage. Understanding the mechanics of this cooling system is essential for boat owners and enthusiasts to ensure the longevity and reliability of their watercraft's engines.

What You'll Learn

- Cooling System: Water jackets and coolant circulation remove heat from the engine

- Heat Exchange: Coolant absorbs heat from the engine and transfers it to the water

- Thermostat: Regulates coolant flow to optimize cooling efficiency

- Coolant Types: Different coolants offer varying protection and performance

- Maintenance: Regular checks ensure proper coolant levels and engine health

Cooling System: Water jackets and coolant circulation remove heat from the engine

Water-cooled boat motors rely on a sophisticated cooling system to maintain optimal engine performance and prevent overheating during operation. The primary component of this system is the water jacket, a network of passages that surrounds the engine's cylinders and internal components. These jackets are designed to absorb and transfer heat away from the engine, ensuring efficient cooling. When the engine is running, the water jackets are filled with a coolant, typically a mixture of water and a special additive. This coolant acts as a heat conductor, absorbing the excess heat generated by the engine's combustion process.

The coolant circulation process is a critical aspect of the cooling system's functionality. As the engine operates, the coolant circulates through the water jackets, continuously removing heat and preventing the engine from overheating. This circulation is achieved through a series of pumps and passages. The engine's cooling system includes a coolant pump, which is driven by the engine itself, ensuring a consistent flow of coolant. This pump forces the coolant through the water jackets, where it comes into direct contact with the hot engine components. As the coolant absorbs heat, it becomes warmer and is then directed to the engine's radiator.

The radiator is another essential component in this cooling process. It is typically located in front of the engine and is designed to dissipate heat from the coolant. The radiator uses the boat's airflow to cool the hot coolant, allowing it to release excess heat into the surrounding environment. After passing through the radiator, the coolant is recirculated back into the engine, completing the cooling cycle. This continuous circulation of coolant through the water jackets and radiator ensures that the engine operates at an optimal temperature, even during extended periods of use.

In addition to the water jackets and coolant circulation, some water-cooled boat motors also employ other cooling techniques. For instance, some engines use a fan that blows air over the radiator to enhance heat dissipation. This fan is often driven by an electric motor or, in some cases, by the engine's auxiliary belt. The combination of water jackets, coolant circulation, and additional cooling methods ensures that boat motors can operate efficiently and reliably, even in demanding marine environments.

Proper maintenance of the cooling system is crucial to its effectiveness. Regularly checking the coolant level and quality is essential to prevent engine damage. Over time, coolant can degrade and lose its ability to absorb heat, so it should be replaced periodically. Additionally, keeping the engine clean and free from debris is vital, as any obstructions in the water jackets could hinder the cooling process. By understanding and maintaining the cooling system, boat owners can ensure their engines remain cool and perform optimally, even in the most challenging marine conditions.

Best Boats for Cruising Corpus Christi Waters

You may want to see also

Heat Exchange: Coolant absorbs heat from the engine and transfers it to the water

The process of heat exchange in a water-cooled boat engine is a critical component of its cooling system, ensuring optimal performance and longevity. When an engine operates, it generates a significant amount of heat, primarily from the combustion of fuel. This heat needs to be managed to prevent overheating, which can lead to engine damage and reduced efficiency. Here's a detailed explanation of the heat exchange process:

In a water-cooled engine, the primary medium for heat exchange is a coolant, typically a mixture of water and a special additive. This coolant is carefully formulated to provide excellent heat transfer properties and corrosion resistance. The engine's cooling system is designed to facilitate the continuous circulation of this coolant, ensuring effective heat dissipation. The process begins with the coolant absorbing heat from various engine components, including the cylinder head, block, and other hot spots. This heat absorption is a result of the coolant's ability to conduct and transfer thermal energy efficiently.

As the coolant absorbs heat, its temperature rises, making it an effective heat carrier. The heated coolant then flows through a series of passages or channels within the engine block, often in a specific route to ensure optimal cooling. These passages are strategically designed to maximize surface area, allowing for efficient heat transfer. The coolant comes into direct contact with the engine's metal surfaces, transferring the absorbed heat to the water. This transfer occurs due to the coolant's high thermal conductivity, which enables it to rapidly conduct heat away from the engine components.

The water, in this case, acts as a heat sink, absorbing and dissipating the heat from the coolant. It is typically circulated through a separate loop, often driven by an engine-mounted water pump. The pump ensures a continuous flow of water, maintaining a steady temperature and pressure within the system. As the water absorbs heat, it becomes warmer and flows towards the engine's heat exchangers, commonly known as radiators.

Radiators play a vital role in the heat exchange process by providing a large surface area for heat dissipation. They are designed with intricate fins and tubes that increase the surface area, allowing the water to release heat to the surrounding air. This heat exchange between the water and the air is crucial in cooling the engine. The cooled water then returns to the engine, completing the cycle, and the process repeats, ensuring the engine operates within safe temperature limits. This efficient heat exchange system is a key factor in the reliability and performance of water-cooled boat motors.

Selecting the Right Grit Sandpaper for Boat Hulls

You may want to see also

Thermostat: Regulates coolant flow to optimize cooling efficiency

A thermostat is a critical component in the cooling system of a water-cooled boat engine, playing a vital role in maintaining optimal engine temperature and performance. Its primary function is to regulate the flow of coolant, ensuring efficient heat dissipation and engine protection. When the engine is operating, the thermostat acts as a valve, controlling the movement of coolant through the engine block and radiator. This regulation is essential because it allows the engine to operate at the ideal temperature range, preventing overheating and potential damage.

The thermostat's design is such that it remains closed when the engine is cold, allowing the engine oil to heat up and lubricate the engine components effectively. As the engine warms up, the thermostat opens, enabling coolant to flow through the engine block and absorb heat. This process is crucial as it helps to maintain a consistent engine temperature, ensuring optimal performance and longevity. The thermostat's ability to control coolant flow is achieved through a precise temperature-sensitive mechanism, typically a bimetallic strip or an electric sensor.

In the closed position, the thermostat prevents coolant from bypassing the engine block, ensuring that the engine oil gains heat and reaches the desired operating temperature. Once the engine reaches the optimal temperature, the thermostat opens, allowing coolant to flow through the engine and radiator system. This regulated flow of coolant is key to efficient heat exchange, as it enables the radiator to dissipate excess heat into the surrounding air.

The thermostat's operation is finely tuned to the specific engine requirements. It is designed to open at a predetermined temperature, often around 180-200°F (82-93°C), which is the ideal range for most boat engines. This temperature range ensures that the engine operates efficiently without overheating, especially during prolonged periods of use or high-load conditions. By regulating coolant flow, the thermostat contributes to the overall reliability and performance of the water-cooled boat engine.

In summary, the thermostat is a vital component that ensures the engine operates within safe temperature limits. Its ability to control coolant flow optimizes cooling efficiency, prevents overheating, and promotes the longevity of the boat engine. Understanding and maintaining the thermostat's functionality is essential for boat owners to ensure their engines perform reliably and efficiently on the water.

Repairing a Boat's Submerged Wiring Harness: Step-by-Step Guide

You may want to see also

Coolant Types: Different coolants offer varying protection and performance

Water-cooled boat motors rely on a sophisticated cooling system to maintain optimal engine temperatures, ensuring efficient operation and longevity. The heart of this system is the coolant, a liquid that absorbs heat from the engine and carries it away to the radiator, where it dissipates into the surrounding air. The choice of coolant is crucial, as different types offer varying levels of protection and performance, impacting the engine's overall health and reliability.

Coolants are typically classified into two main categories: traditional and synthetic. Traditional coolants, often referred to as ethylene glycol-based, have been used for decades and provide basic cooling and corrosion protection. They are cost-effective and widely available, making them a popular choice for many boat owners. However, they may not offer the same level of protection against extreme temperatures or chemical corrosion as synthetic coolants. Synthetic coolants, on the other hand, are engineered to provide superior performance. They often contain additives that enhance heat transfer, prevent engine wear, and offer better protection against corrosion and freezing. Synthetic coolants are more expensive but are known for their stability and ability to maintain engine performance in a wide range of conditions.

One of the key advantages of using the right coolant is its ability to protect the engine's internal components. Coolants with corrosion inhibitors create a protective layer on metal surfaces, preventing rust and corrosion. This is particularly important in marine environments where salt and other contaminants can accelerate corrosion. Additionally, some coolants are designed to provide better protection against engine wear, reducing friction and minimizing the risk of internal damage. For example, coolants with anti-wear additives can help maintain engine performance over extended periods, ensuring that boat motors remain reliable even after prolonged use.

Another consideration is the coolant's ability to handle varying temperatures. Synthetic coolants often excel in this area, as they can maintain their protective properties across a wide temperature range. This is crucial for boat motors, which may operate in different climates and water conditions. Traditional coolants may struggle in extreme temperatures, requiring more frequent changes or the addition of special additives to maintain performance.

In summary, the choice of coolant is a critical aspect of maintaining a water-cooled boat motor. Different coolants offer varying levels of protection and performance, impacting the engine's longevity and reliability. Boat owners should consider the specific needs of their engines, such as temperature extremes and corrosion potential, when selecting a coolant. By choosing the right coolant, boat owners can ensure that their engines remain cool, protected, and in optimal condition for years to come.

Renewing Boat Registration in New Hampshire: A Simple Guide

You may want to see also

Maintenance: Regular checks ensure proper coolant levels and engine health

Regular maintenance is crucial for the longevity and optimal performance of water-cooled boat motors. One of the most critical aspects of this maintenance routine is monitoring and ensuring proper coolant levels. Coolant, often a mixture of water and a special additive, serves multiple purposes in the engine's cooling system. Firstly, it absorbs heat from the engine, preventing overheating, which can cause severe damage. Secondly, it acts as a lubricant, reducing friction between engine components, and thirdly, it contains additives that protect the engine from corrosion and wear.

Checking coolant levels is a straightforward process. It typically involves opening the coolant reservoir, usually located near the engine, and inspecting the liquid level. The reservoir is often marked with a minimum and maximum level, and the coolant should be between these two lines. If the level is low, it indicates a potential leak or excessive evaporation, and immediate action is required. Topping up the coolant to the correct level is essential to prevent engine overheating and ensure the engine's longevity.

In addition to coolant levels, regular checks should also include inspecting the engine's overall health. This involves examining the engine for any signs of damage, leaks, or unusual noises. For instance, if you notice any leaks around the engine block or the cooling system, it could indicate a problem with gaskets or hoses, which need immediate attention. Regularly cleaning the engine and its components can also prevent the buildup of dirt and debris, ensuring efficient operation.

Another critical aspect of maintenance is monitoring the engine's temperature. Overheating can be a sign of a failing cooling system, and it can lead to severe engine damage. Therefore, it's essential to check the engine's temperature gauge during operation. If the temperature rises rapidly or exceeds the recommended range, it may indicate a problem with the cooling system, and further investigation is necessary.

By performing these regular checks and addressing any issues promptly, boat owners can ensure that their water-cooled motors operate efficiently and reliably. Proper maintenance not only extends the engine's lifespan but also reduces the risk of costly repairs and replacements, making it an essential practice for all boat enthusiasts.

Paddles for Large Boats: When Are They Necessary?

You may want to see also

Frequently asked questions

Water-cooled boat motors use a cooling system that circulates water through the engine block to absorb heat generated during combustion. This water is typically sourced from the surrounding environment, such as the lake or river, and is directed through a series of passages and channels within the engine. The water then passes over the engine's cylinders and other components, transferring heat away from the engine and keeping it at an optimal operating temperature.

Water cooling offers several advantages over air cooling in boat motors. Firstly, it provides superior heat dissipation, allowing the engine to operate at higher RPMs and power levels without overheating. This is especially beneficial for high-performance boats that require maximum power output. Additionally, water cooling helps to maintain consistent engine temperatures, reducing the risk of engine damage and improving overall reliability.

The cooling system consists of a water pump, radiator, and coolant (also known as antifreeze). The water pump circulates the water through the engine, pushing it through the radiator where it can exchange heat with the surrounding air. The coolant mixture, which contains additives to prevent corrosion and freezing, is then re-circulated back into the engine to continue the cooling process.

It is not recommended to use tap water directly in the cooling system of a boat motor. Tap water can contain minerals and impurities that may lead to scale buildup, corrosion, and potential engine damage over time. Instead, it's best to use a dedicated coolant mixture specifically formulated for marine applications, which provides excellent protection against heat, freezing, and corrosion.

Regular maintenance of the cooling system is essential to ensure optimal performance and longevity of the boat motor. It is recommended to check the coolant level and condition regularly, typically every few months or as advised by the manufacturer. If any leaks or issues are detected, the system should be inspected and repaired promptly. Additionally, keeping the engine's cooling passages clean and free of debris is crucial for efficient heat exchange.