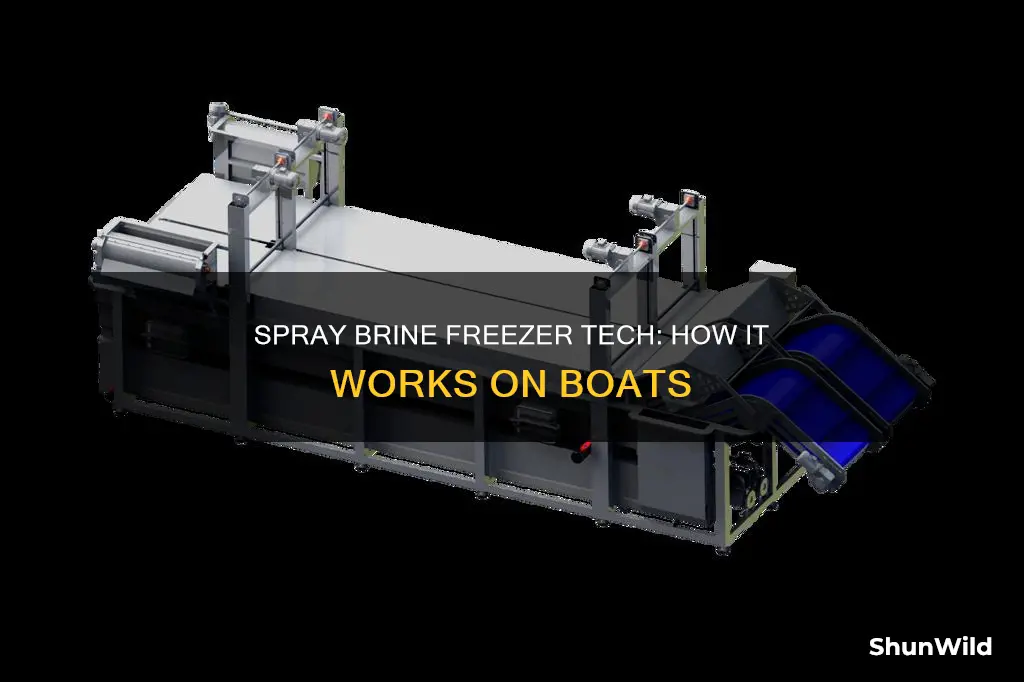

Spray brine freezers are an essential component of refrigeration systems on boats, ensuring that food remains fresh and safe for consumption during extended voyages. These innovative devices utilize a unique process to preserve perishable items without the need for traditional brine solutions, which can be cumbersome and heavy. By employing a spray mechanism, the freezer circulates a brine-free solution, typically a mixture of salt and water, directly onto the food items. This process effectively lowers the freezing point of the food, preserving its quality and texture while maintaining a safe temperature. Understanding the mechanics of these spray brine freezers is crucial for boaters to ensure efficient and reliable food storage, contributing to a comfortable and safe journey.

| Characteristics | Values |

|---|---|

| Technology | Spray brine freezers utilize a process called "brine freezing" or "brine injection." This method involves injecting a concentrated salt solution (brine) into the freezer's evaporator coils. |

| Cooling Process | The brine solution absorbs heat from the freezer's interior, lowering the temperature and freezing the food. This process is more efficient than traditional mechanical refrigeration. |

| Advantages | - No moving parts, reducing maintenance. - quieter operation compared to traditional freezers. - Can achieve lower temperatures, suitable for extended voyages. - Environmentally friendly as it uses natural salt and water. |

| Disadvantages | - Requires regular brine solution replenishment. - Initial setup and installation can be complex. - May require more initial investment compared to conventional freezers. |

| Brine Solution | The brine is typically a concentrated saltwater solution, often with added antifreeze agents to prevent freezing point depression. |

| Evaporator Coils | These coils are strategically placed inside the freezer and are where the brine solution is injected. The coils absorb heat from the freezer's interior. |

| Heat Exchange | The brine solution's heat is transferred to the surrounding air, which is then cooled and recirculated, maintaining the desired temperature. |

| Maintenance | Regular maintenance includes checking brine levels, cleaning coils, and ensuring proper ventilation. |

| Applications | Spray brine freezers are commonly used on sailboats, yachts, and other small vessels where space and weight are limited. |

What You'll Learn

- Cooling System: Spray brine freezers use a cooling system to lower temperatures

- Evaporative Cooling: Brine is sprayed to create a cooling effect through evaporation

- Condensation Process: Moisture in the air condenses on the freezer's surface

- Brine Solution: A brine solution is used to facilitate the cooling process

- Heat Exchange: Brine absorbs heat from the freezer's interior and releases it to the environment

Cooling System: Spray brine freezers use a cooling system to lower temperatures

Spray brine freezers are a popular and efficient method of refrigeration used on boats, particularly for those who require a reliable and compact cooling system. The primary function of these freezers is to maintain a lower temperature to preserve food and beverages, ensuring they remain fresh and edible during extended periods at sea. The cooling system employed by spray brine freezers is both innovative and effective, utilizing a unique process to achieve optimal cooling.

At the heart of this system is a refrigerant, typically a type of brine solution, which is sprayed onto a series of evaporators. These evaporators are strategically designed to maximize surface area, allowing for efficient heat exchange. When the refrigerant comes into contact with the evaporators, it absorbs heat from the surrounding environment, causing it to evaporate. This process is crucial as it helps to lower the temperature of the freezer's interior. The evaporated refrigerant then enters a condenser, where it releases the absorbed heat to the external environment, typically through a heat exchanger.

The key to the spray brine freezer's efficiency lies in the continuous cycle of this process. As the refrigerant evaporates, it draws heat away from the freezer's interior, creating a cooling effect. This is further enhanced by the spray mechanism, which ensures an even distribution of the refrigerant across the evaporators. The spray brine solution is carefully formulated to have a lower freezing point than water, allowing it to remain in a liquid state even at sub-zero temperatures, thus facilitating effective heat absorption.

The cooling system's design also incorporates a thermostat or temperature control unit. This component monitors the freezer's internal temperature and activates the cooling cycle when the set temperature is reached. Once the desired temperature is achieved, the thermostat deactivates the cooling system to prevent overcooling. This automatic regulation ensures that the freezer maintains a consistent and safe temperature for food storage.

In summary, spray brine freezers utilize a sophisticated cooling system that employs a refrigerant, typically a brine solution, to lower temperatures. The spray mechanism ensures efficient heat exchange, while the continuous cycle of evaporation and condensation maintains a consistent cooling effect. This innovative design makes spray brine freezers an ideal choice for boats, providing reliable refrigeration in a compact and effective manner.

Repairing Aluminum Boats: Fixing Bow Damage Efficiently

You may want to see also

Evaporative Cooling: Brine is sprayed to create a cooling effect through evaporation

Spray brine freezers on boats utilize a unique evaporative cooling process to maintain optimal temperatures, especially in marine environments where traditional cooling systems may fall short. This innovative method involves the strategic spraying of brine, a concentrated saltwater solution, to achieve effective cooling. The process begins with the generation of brine, which is typically produced by mixing saltwater with a specific concentration of salt. This brine is then carefully sprayed onto the surface of the freezer's evaporator.

As the brine is sprayed, it undergoes a remarkable transformation. The high-pressure spray ensures that the brine droplets are small, allowing for efficient contact with the air. When these tiny brine droplets come into contact with the surrounding air, a fascinating phenomenon occurs. The process of evaporation takes place, where the liquid brine rapidly transforms into vapor. This evaporation process is a critical aspect of the cooling mechanism.

The key to understanding the cooling effect lies in the principles of evaporative cooling. When the brine evaporates, it absorbs heat from the surrounding environment, including the freezer's interior. This heat absorption is a direct result of the energy required to change the liquid brine into vapor. As a consequence, the temperature of the freezer's interior decreases, creating a cooling effect. The more brine that evaporates, the greater the cooling impact.

This evaporative cooling technique is particularly advantageous for boats due to its ability to provide efficient cooling without the need for complex mechanical systems. The spray brine freezer's design ensures that the brine is evenly distributed, allowing for comprehensive coverage of the evaporator surface. This even distribution promotes optimal heat exchange, ensuring that the cooling effect is consistent and reliable.

In summary, the spray brine freezer's evaporative cooling system is a clever and effective solution for temperature control on boats. By harnessing the power of evaporation, this method provides a natural and efficient way to maintain the desired temperature, ensuring the preservation of perishable goods and creating a comfortable environment aboard the vessel. This innovative approach to cooling showcases the ingenuity of marine engineering, addressing the unique challenges posed by the marine environment.

Marine Battery: Essential Power for Boats

You may want to see also

Condensation Process: Moisture in the air condenses on the freezer's surface

The operation of spray brine freezers on boats relies on a fascinating process called condensation, which is the transformation of water vapor in the air into liquid water. This process is particularly crucial in the context of marine environments, where maintaining optimal temperatures for food preservation is essential. When a spray brine freezer is in operation, the air inside the freezer compartment contains moisture, often in the form of water vapor. This moisture is present due to the natural humidity of the marine environment and the breathing of the occupants on the boat.

As the freezer operates, it creates a temperature difference between the inside and outside. The interior of the freezer is cooled to a temperature below the dew point of the surrounding air, which is the temperature at which the air becomes saturated and can no longer hold all the water vapor it contains. At this point, the excess moisture in the air starts to condense onto the surface of the freezer. This condensation process is a result of the water vapor in the air losing its ability to remain in the gaseous state and transforming into tiny water droplets or ice crystals, depending on the temperature.

The freezer's surface, often made of a cold, smooth material like stainless steel or aluminum, provides an ideal surface for this condensation to occur. As the moisture-laden air comes into contact with the cold freezer walls, the water vapor condenses, forming a thin layer of water or a light frost, depending on the temperature and humidity levels. This condensation is a natural and essential part of the freezing process, as it helps to remove the moisture from the air, preventing it from freezing inside the freezer and causing potential issues.

The spray brine system, an innovative feature of these freezers, further enhances the condensation process. It involves spraying a brine solution (a mixture of salt and water) onto the freezer's interior surfaces. The brine acts as a desiccant, absorbing moisture from the air and promoting more efficient condensation. This process is particularly effective in marine environments, where the air often contains higher levels of humidity due to the proximity to water bodies. By actively managing the moisture content, spray brine freezers ensure that the food stored inside remains frozen and preserved, even in challenging marine conditions.

Understanding the condensation process is key to appreciating the efficiency of spray brine freezers. By utilizing the natural tendency of water vapor to condense at lower temperatures, these freezers create an environment where moisture is continuously removed, preventing ice buildup and ensuring the preservation of food. This innovative technology is a testament to the ingenuity required to meet the unique challenges of food storage in marine environments.

The Ultimate Guide to Replacing Boat Rollers Like a Pro

You may want to see also

Brine Solution: A brine solution is used to facilitate the cooling process

A brine solution is a key component in the operation of spray brine freezers, which are commonly used on boats for food preservation. This method of freezing relies on a unique process that utilizes salt and water to create a cooling effect. Here's a detailed explanation of how it works:

The brine solution is prepared by mixing salt with water in a specific ratio. This mixture is carefully controlled to ensure the concentration of salt is optimal for the freezing process. The solution is then sprayed onto the food items or the freezer's interior. When the brine solution comes into contact with the food or the freezer walls, it undergoes a phase change, similar to the freezing of water. As the salt dissolves in the water, it lowers the freezing point, allowing the solution to remain in a liquid state even at sub-zero temperatures. This is a crucial step as it enables the efficient transfer of heat from the food or freezer surface to the brine solution, facilitating rapid cooling.

The cooling process is achieved through the principles of heat transfer. As the brine solution absorbs heat from the food or freezer surface, it freezes, forming a layer of ice. This ice layer acts as an insulator, preventing further heat transfer and maintaining the low temperature. The spray brine freezer's design often includes a system that ensures an even distribution of the brine solution, ensuring all parts of the food or freezer are exposed to the cooling agent. This even coverage is essential for consistent freezing and preservation.

One of the advantages of using a brine solution is its ability to provide rapid cooling, which is particularly beneficial for perishable goods on boats. The solution's low freezing point allows for quick temperature drops, preserving the quality and freshness of the food. Additionally, the brine solution's natural preservative properties can help extend the shelf life of stored items.

In summary, the brine solution is a critical element in spray brine freezers, enabling efficient cooling and preservation on boats. Its unique properties allow for rapid freezing, even at low temperatures, making it an ideal method for food storage in marine environments. Understanding this process can help boat owners and operators optimize their food preservation systems.

Boat Engine Freezing: Prevention and Emergency Response Strategies

You may want to see also

Heat Exchange: Brine absorbs heat from the freezer's interior and releases it to the environment

Spray brine freezers on boats utilize a unique heat exchange process to maintain the desired temperature within the freezer compartment. This system relies on the properties of brine, a solution of salt and water, to facilitate efficient heat transfer. Here's a detailed explanation of the heat exchange mechanism:

When the spray brine freezer is operational, brine is circulated within the system. This brine acts as a heat exchange medium, absorbing heat from the interior of the freezer. The process begins with the brine being sprayed or circulated through the freezer's interior space. As the brine comes into contact with the freezer walls, shelves, and other surfaces, it absorbs heat from these areas. This heat absorption is a result of the temperature difference between the brine and the freezer's interior. The brine, being a salt solution, has a higher specific heat capacity compared to pure water, allowing it to absorb more heat energy.

The absorbed heat energy is then transferred to the surrounding environment. Brine, now heated, is directed towards the freezer's exterior or the boat's external environment. Here, the heated brine releases its absorbed heat to the surroundings. This release of heat occurs due to the temperature difference between the heated brine and the external environment. The heat exchange process is facilitated by the circulation and spraying mechanisms within the system, ensuring efficient heat transfer.

This method of heat exchange is crucial for maintaining the desired temperature within the freezer. By continuously absorbing heat from the interior and releasing it to the environment, the spray brine freezer can effectively cool and preserve food items. The brine's ability to absorb and transfer heat efficiently makes it an ideal medium for this process, ensuring the freezer's performance and longevity.

In summary, the heat exchange process in spray brine freezers involves the brine's role as a heat absorber and transporter. By utilizing the brine's properties, these freezers can efficiently cool their interiors, providing a reliable and effective cooling solution for boats and other marine applications. This innovative system showcases how heat exchange principles can be applied to create practical and sustainable cooling technologies.

Westworld RV Boat Outdoor Show: Opening Times Explored

You may want to see also

Frequently asked questions

A spray brine freezer is a type of refrigeration system designed specifically for marine environments. It operates by using a brine solution, typically a mixture of water and a salt or sugar solution, which is sprayed onto the evaporator coils. This process absorbs heat from the surrounding air, cooling the boat's interior. The brine solution then drips back into the system, where it is re-frozen and re-used, making it an efficient and environmentally friendly cooling method.

These freezers offer several benefits for boats. Firstly, they provide excellent cooling performance without the need for a separate compressor, making them compact and lightweight. The use of brine as a refrigerant is environmentally friendly, as it doesn't deplete the ozone layer. Additionally, spray brine freezers are known for their reliability and low maintenance requirements, making them a popular choice for marine refrigeration.

Brine production is a crucial part of the process. The brine solution is typically made by dissolving salt or sugar in water, creating a concentrated mixture. This brine is then circulated through the system, where it absorbs heat from the air. As the brine evaporates, it leaves behind the salt or sugar crystals, which can be recycled or disposed of safely. The process ensures a continuous supply of cold air without the need for frequent refilling of a traditional refrigerant.

Temperature control is achieved through a feedback loop system. Sensors monitor the temperature inside the freezer compartment and adjust the brine flow accordingly. If the temperature drops too low, the system reduces brine circulation to prevent overcooling. Conversely, if the temperature rises, more brine is added to lower it. This automatic adjustment ensures optimal temperature stability, even in varying environmental conditions.

Regular maintenance is essential to ensure the longevity of the system. It is recommended to check the brine solution concentration periodically and refill or adjust it as needed. Keeping the freezer clean and free of debris is crucial, especially around the evaporator coils. Additionally, monitoring the system's performance and addressing any issues promptly can help prevent major breakdowns and ensure efficient operation.