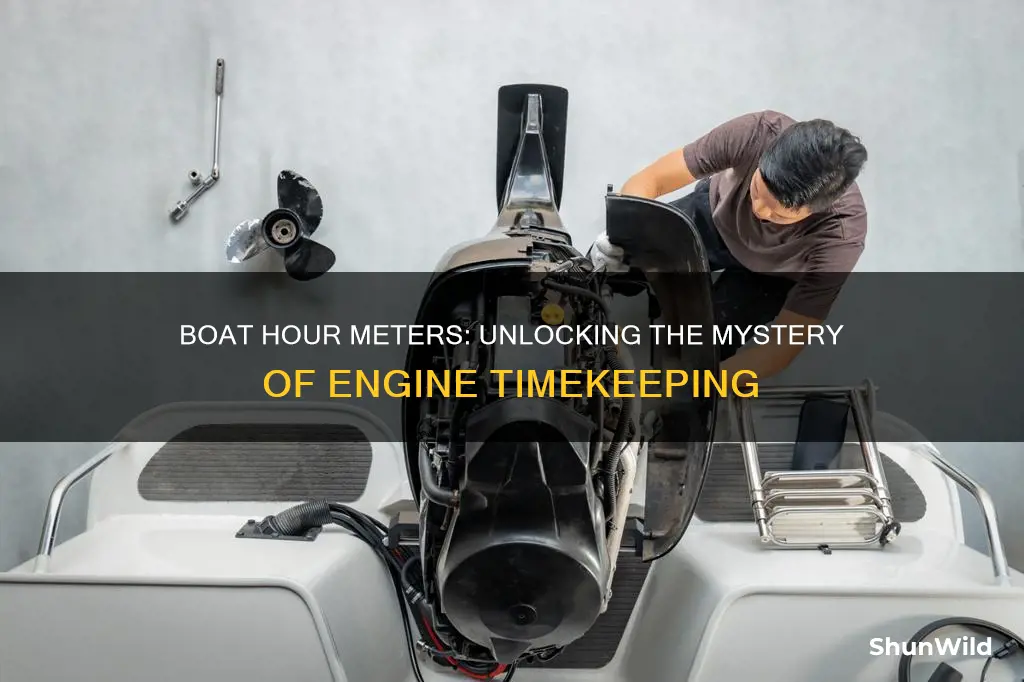

Boat hour meters are essential devices for monitoring the operation time of marine engines, providing valuable data for maintenance and fuel efficiency. These meters track the hours an engine has been running, offering a clear indication of its usage and wear. Understanding how these meters function is crucial for boat owners and operators, as it allows them to optimize engine performance, plan maintenance schedules, and ensure compliance with regulations. This paragraph introduces the concept of boat hour meters and sets the stage for a detailed explanation of their inner workings.

What You'll Learn

- Boat Hour Meter Basics: Understanding the core function and components of boat hour meters

- Hour Tracking Mechanism: How the meter records operating hours of the boat's engine

- Display and Indicators: Visual representation of hours and potential warning signals

- Calibration and Maintenance: Methods to calibrate and maintain accurate hour readings

- Integration with Boat Systems: How hour meters connect with other boat systems

Boat Hour Meter Basics: Understanding the core function and components of boat hour meters

Boat hour meters are essential devices for monitoring and tracking the operating hours of marine engines, providing valuable data for maintenance, performance evaluation, and compliance with regulations. These meters are designed to accurately record the time an engine has been running, offering a comprehensive overview of its usage. Understanding the core function and components of boat hour meters is crucial for boat owners and operators to ensure proper maintenance and longevity of their vessels.

The primary function of a boat hour meter is to measure and display the cumulative running time of the engine. It does this by monitoring the electrical current drawn by the engine's starter motor or alternator. When the engine is started, the hour meter begins counting, and it continues to do so as long as the engine is running. This real-time tracking allows for precise recording of engine operation, which is particularly important for larger vessels or commercial boats where engine maintenance and service intervals are critical.

Key components of a boat hour meter include the sensor, display unit, and control circuitry. The sensor is typically located near the engine and is responsible for detecting the electrical current. It converts this current into a signal that the display unit can interpret. The display unit, often mounted in a visible location on the boat's dashboard or console, shows the current and total running hours. Modern meters may also include additional features like reset buttons, alarm settings, and data logging capabilities.

Boat hour meters are designed to be durable and withstand the harsh marine environment. They are often waterproof and protected against corrosion, ensuring they can operate reliably in various weather conditions. Some meters also feature shock resistance, making them suitable for rough waters and potential impacts. Proper installation is crucial to ensure accurate readings, and it is recommended to consult the manufacturer's guidelines or seek professional assistance for optimal placement.

In summary, boat hour meters are specialized devices that play a vital role in engine management and maintenance. By providing an accurate record of engine running hours, they enable boat owners to schedule maintenance, optimize performance, and ensure compliance with regulations. Understanding the meter's function and components allows for better utilization and maintenance, ultimately contributing to the longevity and reliability of marine engines.

Exploring Sebastian Inlet: Best Boat Launch Spots

You may want to see also

Hour Tracking Mechanism: How the meter records operating hours of the boat's engine

The hour meter on a boat is a crucial component for monitoring and tracking the engine's operating hours, providing valuable data for maintenance and ensuring the engine's longevity. This mechanism is designed to accurately record the time the engine has been running, which is essential for various reasons. Here's an overview of how this tracking system works:

Sensor and Input: At the heart of the hour meter is a precision sensor that is directly connected to the boat's engine. This sensor is typically a magnetic or optical device that detects the rotational speed of the engine's crankshaft. As the engine turns, the sensor triggers an electrical signal, which is then used to calculate the operating hours. This real-time data is critical for accurate tracking.

Microprocessor and Data Processing: Modern hour meters employ microprocessors to process the sensor data. These processors are highly sensitive and can measure even the smallest changes in engine speed. They convert the raw sensor data into a digital format, ensuring precision and accuracy. The microprocessor also performs calculations to determine the exact operating time, taking into account any variations in speed and load.

Display and Readout: The processed data is then displayed on a clear and easy-to-read screen, often with a digital readout. This display shows the total operating hours, providing a quick reference for the boat owner or operator. Some advanced meters may also offer additional features like cumulative trip hours, reset options, and error codes, making it a comprehensive tool for engine management.

Calibration and Accuracy: To ensure reliability, hour meters are calibrated to match the engine's specifications. This calibration process involves setting the meter to the correct engine speed and load, ensuring that the recorded hours are accurate. Regular maintenance and calibration are essential to maintain the meter's precision over time.

Benefits of Hour Tracking: The primary purpose of this mechanism is to provide an accurate record of engine usage. This information is vital for scheduling maintenance, as it helps determine when an engine requires servicing or repairs. Additionally, it allows boat owners to track fuel consumption and engine performance over time, enabling better decision-making regarding engine care and potential upgrades.

Exploring Farallon Islands: A Boat Trip from SF

You may want to see also

Display and Indicators: Visual representation of hours and potential warning signals

The display and indicators on a boat hour meter are crucial components that provide a visual representation of the vessel's operating hours, offering both critical information and potential warning signals to the operator. These displays are designed to be easily readable, even in varying lighting conditions, ensuring that the operator can quickly grasp the current operating time and any alerts.

The primary display unit typically consists of a digital or analog clock face, clearly indicating the hours and minutes. This display is often backlit, ensuring visibility during low-light conditions, such as early morning or evening operations. Some advanced hour meters may also include a date display, providing additional information for extended voyages. The clock face is usually centered on the meter, making it easily observable from the helm or any other strategic location on the boat.

In addition to the primary display, boat hour meters often incorporate various indicators to convey different messages. These indicators can include warning lights or LEDs that illuminate when specific conditions are met. For instance, a low-fuel indicator might light up when the fuel level reaches a critical point, prompting the operator to refuel. Similarly, a battery indicator could alert the operator to a low battery condition, ensuring the vessel's electrical systems remain functional.

Another essential indicator is the 'running' or 'on' light, which illuminates when the engine is in operation. This light is crucial for the operator's awareness, especially when the boat is in motion or during extended periods of use. Some hour meters also feature a 'chime' or audible alert, which can be set to sound at predefined intervals or when specific conditions are met, further enhancing the operator's ability to monitor the vessel's status.

The design and placement of these indicators are carefully considered to ensure they are easily noticeable and do not distract from the primary display. Often, the indicators are positioned in a way that they can be seen from multiple angles, ensuring the operator can quickly assess the boat's status without diverting their attention from the task at hand. This comprehensive visual representation of hours and potential warning signals is a key feature that sets boat hour meters apart, providing a vital safety and operational advantage.

Sailing Adventure: May 16 Concrete Boat Sets Sail

You may want to see also

Calibration and Maintenance: Methods to calibrate and maintain accurate hour readings

Calibration and maintenance are crucial aspects of ensuring the accuracy and longevity of boat hour meters. Here's a detailed guide on how to calibrate and maintain these essential instruments:

Calibration Process:

- Hour Meter Calibration: Calibration is the process of adjusting the hour meter to match the actual running time of the engine. Start by running the engine for a known period, such as one hour, and then stop it. Note the reading on the hour meter. If the reading is not exactly one hour, you'll need to calibrate it. Use a calibrated timer or stopwatch to measure the actual running time accurately. Adjust the hour meter's settings to match this value. This process ensures that the meter provides an accurate representation of engine hours.

- Resetting: Before calibration, ensure the hour meter is reset to zero. This can usually be done by pressing and holding a specific button on the meter for a few seconds until the display resets.

- Precision Tools: For precise calibration, invest in a high-quality stopwatch or timer with excellent accuracy. Digital timers with split-time capabilities are ideal for this task.

Maintenance Tips:

- Regular Cleaning: Keep the hour meter clean and free from dirt and grime. Use a soft cloth to wipe down the display and the surrounding area. Ensure no moisture or cleaning agents damage the meter's components.

- Battery Care: If your boat hour meter is battery-powered, regularly check and replace the batteries. Corroded or weak batteries can lead to inaccurate readings. Consider using high-quality, long-lasting batteries to minimize maintenance.

- Visual Inspection: Periodically inspect the hour meter for any signs of damage or wear. Look for cracks, corrosion, or loose connections. If any issues are found, consult a professional for repairs or replacements.

- Environmental Factors: Protect the hour meter from extreme temperatures and direct sunlight, as these can affect its performance and longevity. Consider using a protective cover or mounting the meter in a well-ventilated, cool area.

- Professional Servicing: For complex issues or if you're unsure about maintenance, seek professional assistance. Certified technicians can provide expert calibration and maintenance services, ensuring your hour meter remains accurate and reliable.

Remember, proper calibration and regular maintenance will ensure your boat hour meter provides accurate engine hour readings, which are essential for various applications, including insurance, maintenance scheduling, and resale value.

The Ultimate Guide to Redecking Your Aluminum Boat

You may want to see also

Integration with Boat Systems: How hour meters connect with other boat systems

Boat hour meters are essential devices for monitoring and tracking the operation of various systems on a vessel. These meters are designed to integrate seamlessly with different boat systems, providing valuable data and ensuring optimal performance. The integration process involves connecting the hour meter to the boat's electrical and mechanical systems, allowing for real-time monitoring and data collection.

One of the primary connections is with the boat's engine system. Hour meters can be linked to the engine control unit (ECU) or the ignition system. By monitoring the engine's running time, the meter can accurately record the hours of operation, which is crucial for maintenance and warranty purposes. This integration ensures that boat owners and operators can easily track engine usage, schedule maintenance, and comply with any industry regulations regarding engine hours. For example, some boat manufacturers require specific engine hours to be logged for warranty claims, and hour meters facilitate this process.

In addition to the engine, boat hour meters can also be integrated with other critical systems, such as the generator, propulsion, and auxiliary systems. For the generator, the meter can monitor its running time, providing insights into its performance and maintenance requirements. This is particularly useful for backup power systems, ensuring that the generator is properly maintained to avoid unexpected failures. Similarly, for the propulsion system, the hour meter can track the hours of the propeller or shaft, helping to identify wear and tear, and ensuring timely repairs or replacements.

The integration process often involves specialized wiring and sensors. These sensors are connected to the relevant systems, such as the engine's sensors for temperature, speed, and fuel consumption. By gathering data from these sensors, the hour meter can provide a comprehensive overview of the boat's performance. For instance, it can calculate fuel efficiency, monitor engine temperature to prevent overheating, and detect any unusual operating patterns. This level of integration allows boat owners to make informed decisions about maintenance, troubleshooting, and optimizing their vessel's performance.

Furthermore, the data collected by boat hour meters can be transferred to a central monitoring system or a digital display on the boat's dashboard. This real-time display provides an at-a-glance view of the vessel's operation, making it easier for operators to manage and maintain their boat. The integration with other boat systems ensures that the hour meter becomes a central hub for monitoring, providing a comprehensive solution for boat owners and operators.

Replacing Boat Throttle Trim Switch: A Step-by-Step Guide

You may want to see also

Frequently asked questions

A boat hour meter, also known as a boat speed and hour counter, is an electronic device used on boats to measure and record the vessel's operating hours. It tracks the time the engine has been running and can also display the speed of the boat when it is in motion.

These meters typically have a magnetic sensor that is attached to the engine's flywheel or pulley. As the engine rotates, the sensor sends signals to the meter, which then calculates and displays the total operating time. This method ensures accurate tracking of engine usage.

Yes, most boat hour meters are designed with a reset function. This feature allows boat owners to easily reset the meter to zero when necessary, such as at the start of a new season or when selling the boat. The reset can usually be done by pressing a button or using a remote control.

Absolutely! Boat hour meters provide several advantages. They help boat owners keep track of engine maintenance schedules, as most manufacturers recommend specific operating hours for engine servicing. Additionally, these meters can be useful for insurance purposes, as they provide proof of engine usage and can potentially lower insurance premiums for well-maintained boats.