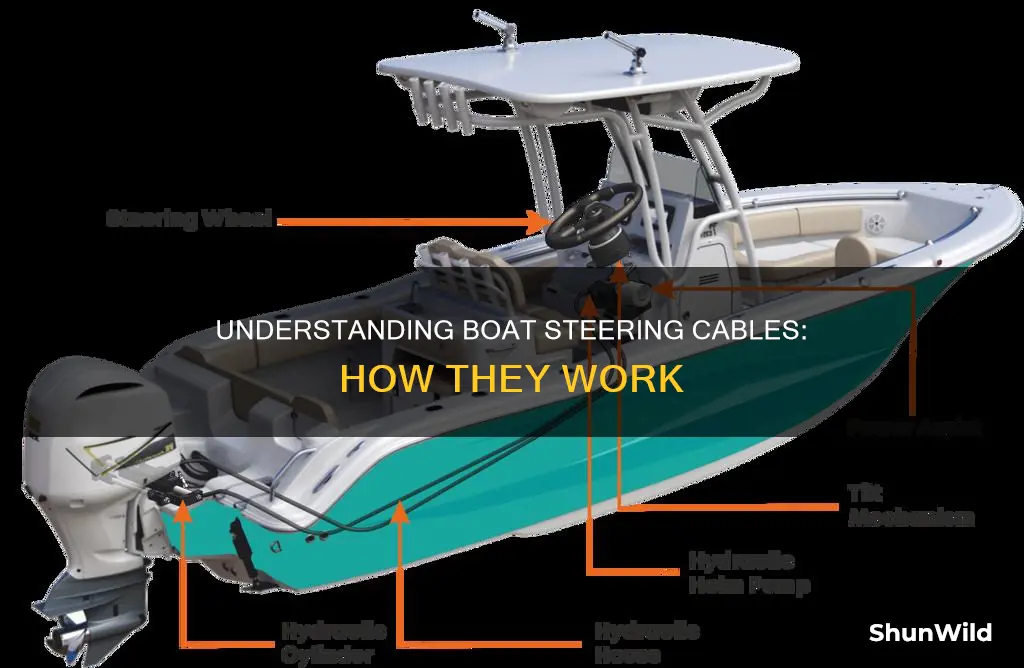

Boat steering systems are an important but often overlooked component of a vessel. There are several types of steering systems, including mechanical, hydraulic, and electronic, each with its benefits and drawbacks. Mechanical steering systems are ideal for smaller boats with engines under 100 horsepower and are the most common type. They use a push-pull cable that connects the steering wheel and helm to the outboard motor. Hydraulic steering systems, on the other hand, are more suitable for larger boats with high-torque engines and provide a smooth and lightweight steering experience. They use a hydraulic hose to control the steering and have the advantage of being more resistant to corrosion. Electronic steering systems are also an option, with some modern ships replacing the steering wheel with a toggle that remotely controls an electric or hydraulic rudder drive.

| Characteristics | Values |

|---|---|

| Steering System Types | Mechanical, Hydraulic, Electronic |

| Mechanical Steering System Types | Rack and Pinion System, Rotary Boat Steering |

| Hydraulic Steering System Parts | Helm, Steering Cylinder, Hydraulic Hoses and Fittings, Mounting Hardware, Hydraulic Fluid |

| Mechanical Steering System Parts | Helm, Cables, Gearing, Installation Kit |

| Helm Types | Rotary, Reduction Gear, Planetary Gear, Rack and Pinion |

| Cable Steering System Maintenance | Regular Inspection, Cleaning and Lubrication, Removal of Cable Connection for Extended Storage |

| Hydraulic Steering Cost | Around $2,000 |

| Mechanical Steering Cost | $179-$299 |

What You'll Learn

The role of the helm

There are two main types of helms: rotary and rack and pinion. The rotary helm is the most common type, using gears to turn the rudder. It is housed behind the instrument panel and consists of a hydraulic pump and valves. When the steering wheel is turned, the pump is activated, and a swash plate presses on small piston pumps. This rotary motion is then converted into a push-pull action on the cable. Most rotary helms use either a reduction gear or a planetary gear system. Reduction gear helms have larger assemblies and are suitable for boats with bigger dashboards, while planetary gear helms take up less space and are ideal for smaller boats.

On the other hand, rack and pinion helms use a pinion gear attached directly to the steering shaft, which engages with a rack gear in a tubular housing. This design offers improved efficiency and reduced friction compared to rotary helms. However, they require more clearance in the dashboard and may not fit in smaller boats.

The choice between a rotary and rack and pinion helm depends on the size and layout of the boat. Both systems play a vital role in converting the rotational input from the steering wheel into the linear output required to move the cable and ultimately steer the boat in the desired direction.

Stratton: A Coast Guard Cutter Worthy of the Seas?

You may want to see also

Steering wheel vs tiller

When it comes to steering a boat, there are two main options: a steering wheel or a tiller. Both have their pros and cons, and the best choice for a boat depends on its size, type, and engine.

Steering Wheel

Steering wheels are more common in larger boats, as they provide more control when heeling or broaching or going over waves. They are also preferred by sailors who want to feel like they are "in charge" while sailing. Wheels are easier for sailing rookies to use, as the motion is similar to driving a car. Additionally, they are more comfortable, as sailors can just sit on the coamings or wedge themselves between the reeling. Steering wheels also look cooler, especially when made of composite materials, giving the boat a sleek and racy look.

However, steering wheels have slower reaction times compared to tillers. They also take up more space in the cockpit, which can be a problem in smaller boats. The mechanical system of a steering wheel has more parts, which means more maintenance and a higher chance of breakdown. Finally, steering wheels can be more tiring for the helmsman, especially when steering for long periods, as they require the helmsman to stand at an angle.

Tiller

Tillars are generally found on smaller boats, as they are simpler, have less maintenance, and are less likely to break down. They provide instant feedback to the helmsman, as the boat goes in the direction the top of the tiller is pointing. Tillers also save space in the cockpit, as they can be tilted upwards when not in use, freeing up the aft area of the boat. They are also easier to maintain, as the steering mechanism is simpler and more straightforward.

However, tillers can be more fatiguing, especially during long cruises or in bad weather, as they require more muscular force to operate. Additionally, it can take some time to get used to steering with a tiller, as the motion is the opposite of what most people are used to from driving a car.

Best Vehicles for Pulling Boats: Powerful Towing Capacity

You may want to see also

Mechanical steering systems

There are three main parts to a mechanical boat steering system: the helm, the steering cable, and the connection kit (if required). The helm is the mechanism behind the instrument panel that converts the wheel's rotary motion into a push-pull motion on the cable. The steering wheel attaches to the helm, which has a round gear around which the cable turns as you turn the wheel. There are two types of helms: reduction gear and planetary gear. Reduction gear helms are the original rotary design and are the most efficient in terms of strength, but they require a large assembly behind the dash. Planetary gear helms are more compact and recommended for boats with small dashboards.

The steering cable is the push-pull cable that moves the rudder or engine in response to the steering wheel being turned. Single-cable steering is suitable for boats with a motor of 130 hp or less, while more powerful engines should use a dual-cable steering system. The connection kit is the hardware that connects the engine or tiller with the steering cable.

It is important to maintain your boat's mechanical steering system to ensure smooth and safe operation. Corrosion of the steering cable can cause stiff movements, seizure, or even total loss of steering control. Regular inspection and lubrication of the system's components are necessary to prevent these issues.

Removing Drain Tubes from Aluminum Boats: A Step-by-Step Guide

You may want to see also

Hydraulic steering systems

There are two main parts to hydraulic boat systems: the helm and the cylinder. The helm is made of a hydraulic pump and valves, and it converts the rotating motion of the steering wheel into a push-pull action on the cable, directing the rudder to move left or right. The cylinder moves when fluid is pumped from the helm after the wheel is turned, acting between two points on the outboard without exerting any force on the hull or deck.

The choice between a hydraulic and a mechanical steering system depends on the size of the boat and the type and size of the motor. Hydraulic steering is usually used with mid-to-high horsepower outboard motors and boats that are 10 metres and above in length, moving at high speeds. Mechanical steering systems, on the other hand, are used in smaller boats up to 10 metres in length.

There are different types of hydraulic steering systems, including full hydraulic, power-assist, electro-hydraulic, and integrated hydraulic steering systems. The right system depends on the boat's features, budget, and personal preferences. Factors to consider include the size of the boat, the type of motor, and the desired number of turns lock-to-lock.

Brighten Your Boat Bookshelf: Top Lighting Tips

You may want to see also

Steering cable maintenance

To keep your boat's steering cable in good condition, it is important to perform regular maintenance. This will ensure that you have reliable and proper control of your boat at all times. Lack of maintenance can lead to stiff steering and, in extreme cases, cable seizure. Here are some detailed instructions on how to maintain your boat's steering cable:

- Inspection Frequency: It is recommended to inspect your steering cable at least two to three times per season or twice a year.

- What to Inspect: Begin by checking the cable jacket for any signs of damage, such as cracks or cuts. Pay close attention to both ends of the cable and inspect the surrounding hardware for any signs of corrosion, wear, or rust. Also, check if the cable is difficult to move.

- Replacing Parts: If you notice any damage or if the cable is hard to move, it is important to replace the affected parts immediately to avoid dangerous situations while out on the water. Steering cables and their components cannot be repaired, so replacement is necessary.

- Disassembling and Cleaning: Remove the steering cable's telescoping ram from the tilt tube. Clean the inside of the tilt tube thoroughly and remove any corrosion with a wire brush. Wipe away all loose material and lubricate the tilt tube with water-resistant marine grease.

- Lubricating the Telescoping Ram: Use a brass wire brush to scour the steering cable's telescoping ram. Wipe it clean and lubricate the sliding parts of the telescoping ram with water-resistant marine grease.

- Reassembling: Reassemble the parts, ensuring that all fasteners are tight and correctly installed. Make sure there is no binding or excessive free play in the moving parts. Use locking fasteners to prevent vibration from loosening the connections and potentially causing steering failure.

- Hose Replacement: Always replace hoses that have damage to the plastic outer jacket.

- Seasonal Storage: If your boat will not be used for an extended period, such as an entire season, remove the cable output from the tube and store it separately.

Safety Equipment Essentials for Small Boat Owners

You may want to see also

Frequently asked questions

The three main types of steering are tiller steering, mechanical steering, and hydraulic steering. Tiller steering is where a tiller handle is attached to the outboard motor. Mechanical steering uses a push/pull cable to connect the steering wheel to the outboard motor. Hydraulic steering pumps fluid through a hydraulic line into a cylinder that controls the steering.

When the driver turns the steering wheel, the helm converts this rotation to a push or pull motion on the steering cable, which turns the outboard, rudder, and prop.

It is recommended to lubricate the steering cable at least twice a year. To do this, disconnect the link arm from the steering cable, undo the large lock nut from the support tube, and pull the cable out. Clean the ram and the tube, then re-grease them with waterproof marine grease.