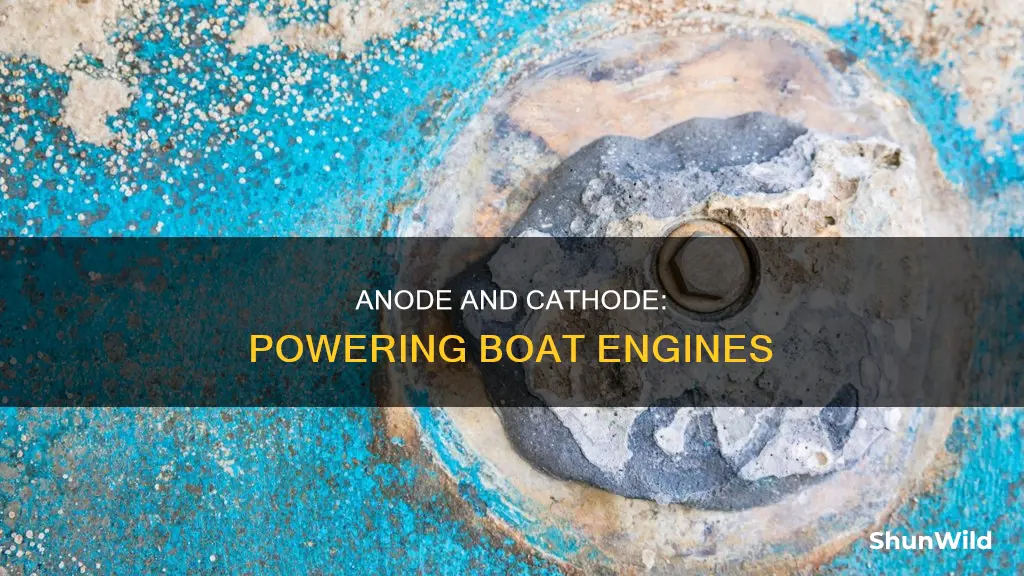

Boat engines and steering components are susceptible to galvanic corrosion, which occurs when two dissimilar metals are immersed in a conductive solution and electrically connected. This process can be understood by thinking of saltwater as a gigantic battery. An electrolyte current flow occurs between the saltwater, hydrogen and oxygen in the water, and the metal. As the water flows over the engine metal, the metal turns into an anode as negatively charged ions flow from it to a cathode. The cathode is usually another nearby metal that is dissimilar in nature. To prevent galvanic corrosion, boats are fitted with sacrificial anodes, which are made from metals such as zinc, aluminium, or magnesium. These metals sacrifice themselves by corroding faster than the other metal parts of the boat, thereby preserving the boat's metal components.

| Characteristics | Values |

|---|---|

| Purpose | Protect boat engine from corrosion |

| Function | Corrode faster than the boat's metal parts, preserving them for longer |

| Placement | Underneath the boat, attached to all metal parts and submerged |

| Materials | Zinc, aluminium, magnesium |

| Replacement | When corroded to around 40%-50% |

What You'll Learn

How sacrificial anodes work

Sacrificial anodes, also known as outboard anodes, are essential for protecting boat engines and underwater metals from corrosion. They are called "sacrificial" because they wear away quicker due to the fast rate of corrosion, essentially "sacrificing" themselves to preserve the boat's metal parts.

When two dissimilar metals are immersed in an electrolyte (like saltwater) and electrically connected, a weak battery is formed, with a current flowing between the two metals. This is the principle of galvanic corrosion, which can destroy underwater metal in a boat.

Sacrificial anodes are made of zinc, aluminum, or magnesium, and are placed on another metal, becoming physically or electrically connected. They are specifically designed for different areas of the boat, including the engine, hull, and propeller shaft to provide maximum protection.

In the context of galvanic corrosion, the anode is the metal that is more resistant to corrosion, while the cathode is the base metal that is less resistant and gives off electrons to the anode. The anode will corrode first, protecting the other metal from damage.

The choice of anode material depends on the type of water the boat will be used in. Zinc anodes are suitable for saltwater, as they have a slower dissolution rate. Aluminum anodes are suitable for both saltwater and brackish water, as they have a higher electrical capacity and can be smaller and more compact. Magnesium anodes are best suited for freshwater, as they have a lower open circuit potential and increased longevity in this environment.

To ensure optimal performance, sacrificial anodes should be strategically placed, remain submerged, and be free of paint and other solvents to maintain conductivity. Regular inspection and replacement of anodes are crucial to maintain effective protection against corrosion.

Essentials for Outfitting a 15-Foot Boat

You may want to see also

The role of anodes in preventing galvanic corrosion

Galvanic corrosion occurs when two dissimilar metals, such as a stainless-steel propeller and an aluminium outdrive, are immersed in a conductive solution like saltwater and are electrically connected. This sets up a giant battery cell, with one metal acting as the anode and the other as the cathode. The anode, or less noble metal, will have a negative charge and will be used up in the process of generating electricity, leading to galvanic corrosion.

By introducing an anode made of zinc, aluminium, or magnesium, we can control and direct this corrosion. These metals are more active and more willing to corrode, sacrificing themselves to protect the other metal parts of the boat. The anode becomes the replacement anode in the corrosion process, corroding away while preserving the engine and underwater metal components.

To ensure optimal performance, anodes should be strategically placed and remain submerged. They should also be replaced regularly, typically when they are about half corroded or once a year. The type of anode used depends on the water type, with zinc being preferred for saltwater, aluminium for brackish water, and magnesium for freshwater.

In summary, anodes play a vital role in preventing galvanic corrosion by attracting and absorbing the ions that would otherwise damage the boat's metal parts. By corroding themselves, anodes preserve the integrity of the boat's engine and underwater components, making them an essential part of boat maintenance.

Filing for a Lost Boat Title in Illinois: A Guide

You may want to see also

The importance of anodes in protecting boat engines

Anodes are essential to protect boat engines and underwater metals from galvanic corrosion. They are also called sacrificial anodes because they wear away quicker due to the fast rate of corrosion, essentially 'sacrificing' themselves to preserve the boat's metal parts.

Galvanic corrosion occurs when two dissimilar metals are immersed in a conductive solution, such as saltwater, and are electrically connected. This forms a weak battery where some current flows between the two metals. The base metal, which is less resistant to corrosion, gives off electrons to the noble metal, which is more resistant, to make up the currents. The anode, made of zinc, aluminium, or magnesium, is a third metal that is even less resistant to corrosion and thus gives up its electrons more quickly to prevent corrosion in the other metals.

The anode is placed underneath the boat, attached to all metal parts, and must remain submerged to perform its function. It must be in good electrical contact with the metal it is protecting, and it should not be painted over or covered in solvents, as this will reduce its conductivity.

Fresh Off the Boat: Streaming in Singapore

You may want to see also

The different types of anodes

Boat anodes are essential for protecting underwater metals from corrosion. They are also known as sacrificial anodes because they corrode faster than the boat's metal parts, preserving them for longer. Anodes are made from different types of metals, such as zinc, aluminium, and magnesium.

The type of anode used depends on the type of water the boat will be used in.

Aluminium Anodes are suitable for salt and brackish water. They have a higher electrical capacity, allowing them to be smaller and more compact than zinc and magnesium anodes. They are also cheaper and more plentiful than zinc.

Magnesium Anodes are only suitable for freshwater applications. They have increased longevity in freshwater due to their lower open circuit potential. They are also much lighter than zinc anodes, which can result in energy and fuel savings.

Zinc Anodes are suitable for saltwater use. They have a higher density and structural composition, providing greater impact strength. They are also the preferred choice for saltwater protection due to their slower dissolution rate. However, they are not suitable for freshwater as they develop an insoluble coating that inhibits their function.

The placement of anodes is crucial for optimal effectiveness. They are typically placed underneath the boat, attached to all metal parts, and must remain submerged. It is important to ensure that anodes are in good electrical contact with the object they are protecting.

Checking Your Boat Battery: A Step-by-Step Guide

You may want to see also

How to care for and replace anodes

Anodes are essential for protecting your boat's engine from corrosion. They are typically made of zinc, aluminium, or magnesium, and work by attracting and absorbing ions that would otherwise damage your boat's metal parts. To ensure anodes work effectively, they should be placed strategically, remain submerged, and be kept free of paint and other solvents.

Checking and Replacing Anodes:

- Check your hull anode every time your boat is out of the water.

- As a general rule, replace anodes when they have corroded to around 40-50% of their original size. This is typically once a year, but it can vary depending on usage, location, and material.

- When replacing an anode, ensure it is aligned at the same angle as the old anode and has good contact with the metal it is attached to.

- Clean the mounting surface with fine-grit sandpaper to ensure there is no corrosion or build-up.

- Do not paint over sacrificial anodes, as they need to be exposed and in contact with the water to function.

- Keep anodes clear of barnacles and other marine growth.

Other Tips:

- Anodes should be in good electrical contact with the object they are protecting.

- The nearer the anode is to the object being protected, the more effective it will be.

- Anodes should be able to 'see' the object they are protecting. Ions in seawater travel in almost straight lines, so a hull anode placed amidships will not protect anything.

- For wooden boats with a high moisture content, consider using a hanging anode to lessen the effect of alkalinity on the hull.

Repairing Boat Pox: A Comprehensive Guide to Restoration

You may want to see also

Frequently asked questions

Anodes are pieces of metal attached to the boat's engine to protect it from corrosion. They are also known as sacrificial anodes because they corrode instead of the engine metal.

Anodes are made of zinc, aluminium, or magnesium. They are attached to the metal parts of the engine and remain submerged in water. When the boat is in saltwater, the saltwater acts as a giant battery, creating an electrolyte current flow between the saltwater, hydrogen, oxygen, and the metal. The metal turns into an anode as negatively charged ions flow from it to a cathode. The anode then dissolves, carrying bits of itself away.

Galvanic corrosion occurs when two dissimilar metals are immersed in a conductive solution, such as saltwater, and are electrically connected. This creates a weak battery where some current flows between the two metals. One of the metals will corrode, and a voltage will be generated between them.

Anodes are important because they protect the metal components of the engine and steering from corrosion. Without anodes, these metal parts would be damaged by the water, leading to rusted and pitted surfaces.

Anodes should be replaced when they are about half eroded or dissolved, which is typically once a year. However, this may vary depending on usage, location, water temperature, and the quality of the anode.