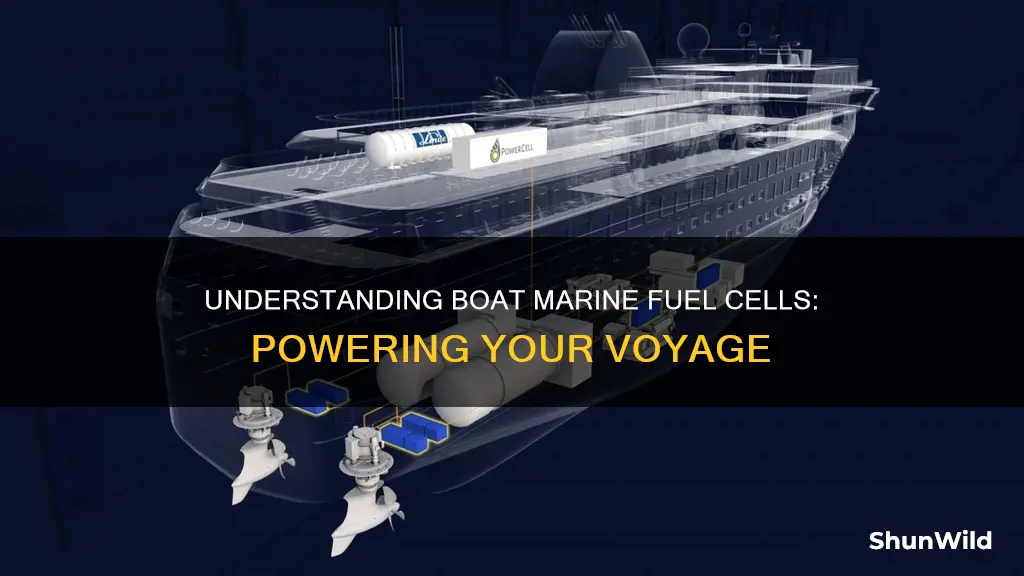

Marine fuel cells are an innovative technology that uses fuel sources such as methanol or hydrogen to generate electricity through a clean electrochemical process. This process produces zero emissions, resulting in quieter operation and a reduced environmental footprint for boats. The most common type of fuel cell used in boats is the proton exchange membrane (PEM) fuel cell, which, like batteries, produces electricity with high efficiency through an electrochemical process. The key difference is that fuel cells use hydrogen fuel as the energy carrier, allowing them to act as generators of electricity as long as hydrogen is supplied. This technology offers a plug-and-play, zero-emission alternative to internal combustion engines, helping the marine industry address greenhouse gas emissions.

| Characteristics | Values |

|---|---|

| Common Type | Proton Exchange Membrane (PEM) Fuel Cell |

| Alternative Type | Solid Oxide Fuel Cell (SOFC) |

| Fuel Source | Hydrogen |

| Hydrogen Extraction Methods | Electrolysis of seawater, Cracking hydrocarbons (diesel, propane) |

| Hydrogen Storage Challenges | Requires high pressures (up to 10,000 lbs per square inch) and custom-built cylinders, which are heavy and expensive |

| Electricity Generation | Solar panels, Onboard generator or alternator |

| Fuel Cell Fuel | Methanol |

| Benefits | Clean operation, quiet performance, efficient power generation, reduced maintenance |

| Challenges | Optimizing installations, hydrogen supply and storage, safety concerns, low conversion efficiency, impurities in fuel sources |

What You'll Learn

The 'proton exchange membrane' (PEM) fuel cell

The proton exchange membrane (PEM) fuel cell is the most common type of fuel cell used on boats. It is also known as a polymer electrolyte membrane (PEM) fuel cell.

PEM fuel cells are made up of membrane electrode assemblies (MEAs), which include the electrodes, electrolyte, catalyst, and gas diffusion layers. The membrane must not be electrically conductive, and it must resist gas crossover. PEMs are typically made from perfluorosulfonic acid (PFSA), sold commercially as Nafion and Aquivion. However, these materials are highly toxic and newer polymers, such as SPX3, are being developed to address this issue.

PEM fuel cells operate at lower temperatures (50-100°C) compared to other fuel cells. This lower operating temperature allows for a faster start-up process, but it can also lead to slower reaction rates. To address this issue, sophisticated catalysts and electrodes are used.

- Hydrogen fuel is processed at the anode, where electrons are separated from protons on the surface of a platinum-based catalyst.

- The protons pass through the membrane to the cathode side, while the electrons travel through an external circuit, generating the electrical output of the cell.

- On the cathode side, another precious metal electrode combines the protons and electrons with oxygen to produce water, which is the only waste product.

PEM fuel cells have several advantages, including compact design, high power density, fast start-up time, high efficiency, low operating temperature, and easy and safe handling. However, they also face challenges such as high cost, low durability, and hydrogen storage problems, which limit their widespread commercialisation.

Joystick Boat Driving: Easy and Smooth Maneuvering

You may want to see also

The 'solid oxide' fuel cell (SOFC)

The solid oxide fuel cell (SOFC) is a unique type of fuel cell characterised by its use of a solid oxide or ceramic electrolyte. SOFCs are highly efficient, with low operating costs, and are ideal for a wide range of applications, from vehicles to stationary power generation. They are also environmentally friendly, producing little to no emissions.

SOFCs operate at very high temperatures, between 600 and 1,000 °C. At these temperatures, they do not require expensive catalysts made of platinum group metals. However, this high operating temperature is also the biggest disadvantage of SOFCs, as it results in longer start-up times and mechanical and chemical compatibility issues.

SOFCs use a solid oxide electrolyte to conduct negative oxygen ions from the cathode to the anode. The electrochemical oxidation of the hydrogen, carbon monoxide, or other organic intermediates by oxygen ions occurs on the anode side. The anode is typically the thickest and strongest layer in each individual cell, made from a cermet—a mixture of nickel and the ceramic material used for the electrolyte.

The cathode, or air electrode, is a thin, porous layer on the electrolyte where oxygen reduction takes place. It must be electrically conductive; lanthanum strontium manganite (LSM) is the material of choice for commercial applications due to its compatibility with doped zirconia electrolytes.

The electrolyte is a dense layer of ceramic that conducts oxygen ions. Its electronic conductivity must be kept low to prevent leakage current losses. Popular electrolyte materials include yttria-stabilized zirconia (YSZ), scandia stabilized zirconia (ScSZ), and gadolinium-doped ceria (GDC).

SOFCs can have multiple geometries, including planar and tubular designs. Hundreds of individual cells are connected in series to form an "SOFC stack", and multiple stacks are combined to create a module. These modules can then be clustered together in various configurations to form solutions ranging from hundreds of kilowatts to tens of megawatts.

SOFCs are fuelled by natural gas, biogas, or hydrogen. During operation, ambient air enters the cathode side of the fuel cell while steam mixes with the fuel entering from the anode side to produce reformed fuel. As this fuel crosses the anode, it attracts oxygen ions from the cathode, combining to produce electricity, steam, and carbon dioxide. The steam produced is recycled to reform the fuel, and the electrochemical process generates the heat required to keep the fuel cell warm.

Lake Race Disaster: Boat Capsizes, Chaos Ensues

You may want to see also

Electrolysis

To prevent electrolysis on boats, sacrificial anodes made of zinc or other metals are often used. These anodes are designed to be sacrificed to electrolysis, protecting the more important parts of the boat. Regular maintenance of these anodes is crucial, including keeping them clean and ensuring they are not painted over, as this would render them useless.

Additionally, it is important to check the wiring on the boat, as electrolysis occurs in the presence of an electrical current. In freshwater, there is no need to worry about galvanic corrosion, but if corrosion is occurring, it indicates the presence of a stray current that needs to be addressed.

Another way to prevent corrosion is by using a good coat of protective paint over metal surfaces, which can significantly reduce the risk of a reaction. Corrosion inhibitors, such as chromium gel, can also be used to make metal resistant to corrosion.

It is also important to avoid mixing metals. Using fasteners or components made of dissimilar metals can make the chemical reaction of electrolysis more likely and intense. Keeping the power off when the boat is not in use can also help shut down magnetic fields and prevent the reaction from occurring.

Overall, electrolysis is a significant concern for boat owners, especially those with aluminium boats, and taking proactive measures to prevent it can help maintain the integrity of the boat's metal components.

Boat Registration in Georgia: A Quick Guide to Verification

You may want to see also

Marine fuel cells' clean operation

Marine fuel cells are an innovative technology that offers a clean and environmentally friendly power solution for boats. This clean operation is a significant advantage, especially when compared to traditional generators, as it produces zero harmful emissions or fumes. This makes marine fuel cells ideal for environmentally conscious boaters, as they help reduce the environmental impact of maritime operations.

The clean operation of marine fuel cells is achieved through a unique electrochemical process that converts fuel, typically methanol, into electricity efficiently. This process is much cleaner than conventional power generation methods, resulting in zero emissions and a quieter boating experience. The absence of harmful emissions or fumes also contributes to a more pleasant and safe environment for both the crew and passengers on board.

One of the key benefits of marine fuel cells is their efficiency in power generation. They can convert methanol into electricity efficiently, reducing fuel consumption and extending the cruising range of boats. This not only lowers operating costs but also contributes to a more sustainable marine industry. The efficient power generation of marine fuel cells also translates to reduced maintenance requirements. With fewer moving parts compared to generators, marine fuel cells require less frequent servicing, resulting in cost savings and increased operational uptime.

Furthermore, marine fuel cells offer a quiet performance, significantly reducing noise levels compared to traditional power generation methods. This makes them an attractive option for boats seeking to minimise noise pollution and create a more peaceful environment for passengers and crew. The quiet operation of marine fuel cells is especially advantageous for boats operating in ecologically sensitive areas or seeking to minimise their impact on marine life.

In addition to the environmental and operational benefits, marine fuel cells also offer economic advantages. For example, the HPM marine fuel cell technology boasts over twice the energy efficiency of a conventional diesel generator. It also has a longer life expectancy and lower equipment costs compared to lithium battery systems. This makes marine fuel cells a cost-effective and sustainable option for boat owners and operators, contributing to a brighter and more sustainable future for the marine industry.

Boat Paint vs Gelcoat: What's the Best Option?

You may want to see also

Hydrogen fuel cell engines' benefits

Hydrogen fuel cells are an efficient power source for marine applications, offering a range of benefits over traditional combustion engines and other alternative energy sources.

One of the key advantages of hydrogen fuel cells is their high energy-to-weight ratio. Unlike batteries, which add significant weight and require longer recharge times, hydrogen fuel cells can power heavy loads over long distances without the need for frequent refuelling. This makes them particularly well-suited for marine vessels that require sustained power output and have limited space for energy storage.

Another benefit of hydrogen fuel cells is their environmental impact. Hydrogen fuel cells emit zero harmful pollutants, with water vapour being the only byproduct of the chemical reaction between hydrogen and oxygen. This contributes to improved air quality and significantly reduces the transportation sector's carbon footprint, helping to create carbon-neutral societies.

In addition, hydrogen fuel cells offer a quiet and peaceful boating experience. Unlike traditional generators or engines, fuel cells operate silently and do not produce any harmful emissions or fumes. This makes them ideal for environmentally conscious boaters who want to enjoy the serenity of their surroundings without disturbing nature or their neighbours.

Furthermore, hydrogen fuel cells have reduced maintenance requirements compared to traditional generators. They have fewer moving parts, which means less wear and tear and lower maintenance costs over time. This is especially advantageous for marine applications, where servicing and repairs can be challenging and costly.

While hydrogen fuel cell technology for boats faces challenges, such as the lack of hydrogen supply infrastructure and the high cost of custom-built cylinders, the benefits outlined above highlight its potential as a viable and attractive alternative energy solution for the marine industry.

Best Places to Buy Interlux Boat Paint

You may want to see also

Frequently asked questions

Marine fuel cells are a clean energy source that produces zero emissions, resulting in quieter operation and a reduced environmental footprint. They are also more efficient than traditional generators, as they require less fuel and extend your cruising range.

Marine fuel cells are a type of fuel cell specifically designed for use in boats and other marine vessels. They generate electricity through a clean electrochemical process, using fuel sources such as methanol or hydrogen.

Marine fuel cells convert fuel into electricity through an electrochemical process. In the case of hydrogen fuel cells, the hydrogen fuel is combined with oxygen to generate electricity, with water vapour and heat as the only emissions.