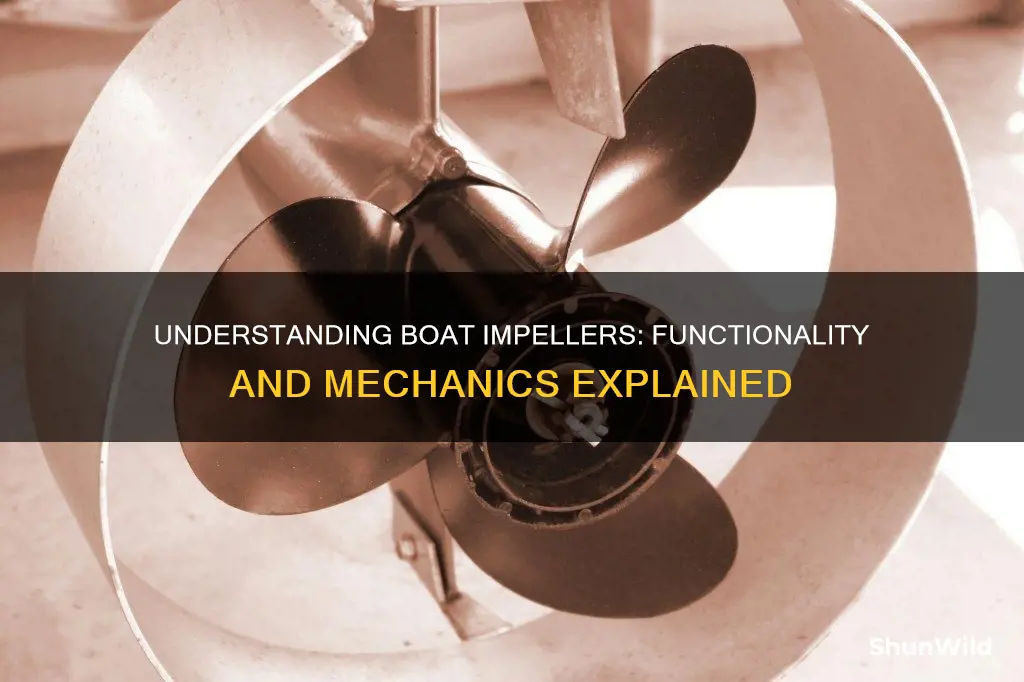

Boat impellers are a vital part of engine cooling. They are used to take in raw water, which is then cycled through the system to keep the engine at a safe operating temperature. The impeller is a hub with flexible rubber fins, which rotate to suck water into the cooling system. Without the impeller, the boat's engine will overheat.

| Characteristics | Values |

|---|---|

| What is it? | A gear-shaped propeller that pumps raw water from outside the boat through dedicated plumbing channels |

| What is it used for? | To cool the engine |

| How does it work? | The impeller rotates, sucking water into the cooling system |

| What is it made of? | Flexible rubber fins |

| How often should it be replaced? | Impellers are durable, but the potential engine damage from a failed impeller is substantial, so it's important to pay attention to its condition |

| What else should I know? | When inserting an impeller, use durable waterproof grease or another lubricating agent suitable for the purpose and approved by the pump manufacturer on the shaft |

What You'll Learn

Boat impellers are gear-shaped propellers that pump raw water from outside the boat

Boat impellers are made of a hub with flexible rubber fins. When the impeller rotates, water is sucked into the cooling system. During operation, water keeps the impeller lubricated and prevents damage. However, the potential engine damage from a failed impeller is substantial. Without the impeller, the boat's engine will overheat.

When inserting an impeller, it is important to use durable waterproof grease or another lubricating agent suitable for the purpose and approved by the pump manufacturer on the shaft. This will make the impeller less likely to become seized to the shaft over time and will make it more readily removable. It is also important to replace the gasket or O-ring sealing the face plate that covers the impeller. Spreading grease or lubricant on the face plate will help to avoid dry start-up friction where the impeller moves against the plate.

Exploring the Quack-tastic Capacity of Duck Boats

You may want to see also

Impellers are made of flexible rubber fins

The impeller is a hub with gear-shaped fins that rotate to pump water. Despite being made of rubber, impellers are durable. During operation, water keeps them lubricated and prevents damage. However, the potential engine damage from a failed impeller is substantial. Without the impeller, the boat's engine will overheat. Therefore, it is important to pay attention to the condition of the impeller and to replace it when necessary.

When inserting an impeller, it is recommended to use durable waterproof grease or another lubricating agent on the shaft. This will help to avoid dry start-up friction and make the impeller more readily removable when it needs to be replaced. Many manufacturers also recommend spreading a little grease on the faceplate.

Parker Boats: Performance and Features Review

You may want to see also

Impellers are lubricated by water

Most inboard and sterndrive boats use a raw water system to cool the engine while it runs. Cold water cycling through the system keeps the engine at a safe operating temperature. When the impeller rotates, water is sucked into the cooling system.

When inserting an impeller, it is important to use durable waterproof grease or another lubricating agent suitable for the purpose and approved by the pump manufacturer on the shaft. This will make the impeller less likely to become seized to the shaft over time and will make it more readily removable. Many manufacturers recommend spreading a little grease on the face plate to avoid dry start-up friction where the impeller moves against the plate.

Essential Electronics for a Safe and Smart Boat

You may want to see also

Impellers need to be replaced regularly

Impellers are a vital part of engine cooling in boats. They are used to take in raw water from outside the boat, which is then cycled through the system to keep the engine at a safe operating temperature. Without an impeller, a boat's engine will overheat.

Impellers are made of rubber, with flexible fins, and are durable. However, they do need to be replaced regularly. This is because, over time, impellers can become seized to the shaft, making them difficult to remove. To avoid this, it is recommended to use a durable waterproof grease or other lubricating agent on the shaft when inserting an impeller. This will make the impeller more readily removable when it needs to be replaced.

Additionally, impellers can wear out over time, especially if they are not properly lubricated. This can lead to potential engine damage, as a failed impeller will cause the engine to overheat. Therefore, it is important for boat owners to regularly check the condition of their impeller and replace it as needed.

When replacing an impeller, it is also important to replace the gasket or O-ring sealing the face plate that covers the impeller. Spreading grease or lubricant on the face plate will help to avoid dry startup friction where the impeller moves against the plate. By following these maintenance and replacement guidelines, boat owners can help ensure the proper functioning of their impeller and engine cooling system.

The Boat Capsized: Ian and Tali's Harrowing Ordeal

You may want to see also

Impellers should be lubricated with waterproof grease when inserted

Impellers are a vital part of engine cooling in boats. They are used to take in raw water from outside the boat, which is then cycled through the system to keep the engine at a safe operating temperature. An impeller is a hub with flexible rubber fins, which rotate to suck water into the cooling system.

In addition to lubricating the impeller, it is important to regularly check it for wear and replace it as needed. Impellers tend to be durable, but the potential engine damage from a failed impeller is substantial. Without the impeller, your boat's engine will overheat.

Exploring Costa Rica's Distance from Florida by Boat

You may want to see also

Frequently asked questions

A boat impeller cools the engine.

A boat impeller is a gear-shaped propeller with flexible rubber fins.

A boat impeller pumps raw water from outside the boat through dedicated plumbing channels.

You should use durable waterproof grease or another lubricating agent on the shaft of the impeller.