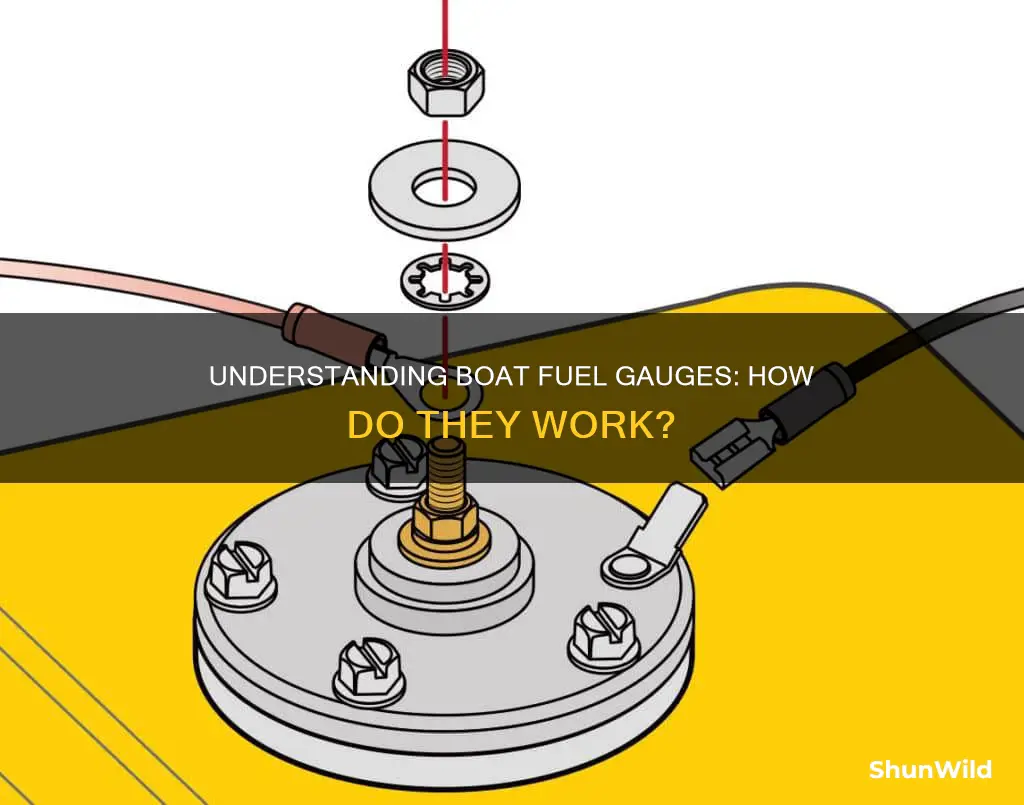

A boat's fuel gauge is a useful tool that can prevent you from getting stranded on the water without fuel. The gauge works by measuring the resistance to ground via the sending unit. The sending unit in the tank is a variable resistor. If the float falls to the bottom, you get an empty reading. If the gauge reads full all the time, it may be broken or receiving an incorrect signal. The gauge must match with the sender in both polarity and in ohms resistance in order to work properly.

| Characteristics | Values |

|---|---|

| The sending unit in the tank | A variable resistor |

| Empty reading | When the float falls to the bottom |

| Full reading | The gauge is broken or receiving an incorrect signal |

| The sender | Acts as a resistor |

| The sender's job | To create a variable potentiometer type resistance |

| The gauge | Knows how to interpret this resistance and uses it for the needle reading |

| The gauge must | Match in both polarity and in ohms resistance with any sender in order to work properly |

| Senders | Some read to ground, some put voltage to gauge |

What You'll Learn

Troubleshooting a broken boat fuel gauge

A broken boat fuel gauge can be a nuisance, but there are ways to troubleshoot and fix the issue. Firstly, it's important to understand how a boat fuel gauge works. The fuel gauge system consists of the gauge itself, the power to the gauge, the fuel sender, the ground to the system, and the fuel sending wire. The fuel sender acts as a variable resistor, with the sending unit in the tank also acting as a resistor. The sender wire completes the circuit for a gauge reading, and the gauge interprets the resistance to provide a needle reading. If the float falls to the bottom, you get an empty reading. If you get a full reading all the time, it could mean that your gauge is broken or receiving an incorrect signal.

To troubleshoot a broken boat fuel gauge, you can start by unhooking the sender wire at the gauge and checking if the gauge drops to empty. This will help determine if the issue is with the sender wire or the sending unit. If the sender wire is grounded or the sending unit is shorted, it could be causing the problem. Additionally, ensure that the gauge and sender match in polarity and ohms resistance, as a mismatch can lead to incorrect readings.

You can also use an ohm meter to test the resistance between the sender post and the ground, which should vary depending on the float level in the tank. If the power is on and you're getting voltage in the S wire, check the voltage between the S wire and the gauge's ground. This will help determine if the gauge is acting as a voltmeter and measuring the voltage correctly.

By systematically testing each component of the fuel gauge system, you can identify and fix the issue, ensuring that your boat fuel gauge works accurately and reliably.

Boat Races: DIY Style for the Win!

You may want to see also

The sender acts as a resistor

A boat's fuel gauge works as an ohm meter. The sender acts as a resistor, creating a variable potentiometer type resistance. The gauge knows how to interpret this resistance and uses it to create a needle reading. The sender's wire must be matched in both polarity and ohms resistance with the gauge in order to work properly. If the float falls to the bottom of the tank, you will get an empty reading. If you get a full reading all the time, this means that your gauge is broken or it is getting an incorrect signal.

To troubleshoot a broken fuel gauge, you can unhook the sender wire at the gauge and see what happens. If the gauge drops to empty, check to see if the sender wire is grounded or the sending unit is shorted. You can also test the fuel gauge, the power to the gauge, the fuel sender, the ground to the system, and the fuel sending wire individually to fix the gauge.

Installing Speakers in Your Boat: A Step-by-Step Guide

You may want to see also

The fuel sender

The sender acts as a resistor, so an ohm meter between the sender post and the ground should vary depending on the float level in the tank. When the power is on, the S wire will have a voltage. The gauge has a ground and a 12v hot wire in addition to the S wire. The sender wire must be matched with the gauge in both polarity and ohms resistance for the gauge to work properly.

If the gauge is not working, the fuel sender is one of the five items that could be causing the problem. The other four are the fuel gauge itself, the power to the gauge, the ground to the system, and the fuel sending wire.

Repairing Your Boat's Backrest: A Step-by-Step Guide

You may want to see also

The gauge and sender must match

To test if the gauge and sender are matched, you can unhook the sender wire at the gauge and see what happens. If the gauge drops to empty, check to see if the sender wire is grounded or the sending unit is shorted. You can also test the power to the gauge, the ground to the system, and the fuel sending wire. These systems will need to be tested individually to fix the gauge.

Bass Boat for Family Fun: Good Idea?

You may want to see also

The sender wire

If the sender wire is grounded or the sending unit is shorted, it can cause the gauge to display an incorrect reading. To troubleshoot this issue, you can unhook the sender wire at the gauge and check if the gauge drops to empty. If the gauge does not drop to empty, it may be getting an incorrect signal from the sender wire.

It is important to note that the gauge and sender must match in order for the system to work properly. If they are not matched, the gauge may read backward or not work at all.

Repairing Cracks in Your Boat's Gelcoat: A Step-by-Step Guide

You may want to see also

Frequently asked questions

The sending unit in the tank is a variable resistor. If the float falls to the bottom, you get an empty reading. If you get a full reading all the time, your gauge is broken or it is getting an incorrect signal.

If your boat fuel gauge is reading full all the time, it is likely that the gauge is broken or it is getting an incorrect signal. You can unhook the sender wire at the gauge and see what happens. If the gauge drops to empty, check to see if the sender wire is grounded or the sending unit is shorted.

There are five items that will cause a boat fuel gauge to not work: the fuel gauge itself, the power to the gauge, the fuel sender, the ground to the system, or the fuel sending wire.