Fiberglass is a popular material used in boat construction, and its addition to wooden floors can significantly enhance the boat's structural integrity and overall strength. When applied to 3/4-inch wood flooring, fiberglass provides a lightweight yet robust reinforcement, improving the boat's ability to withstand pressure and impact. This composite material, when properly bonded to the wood, creates a sturdy and durable surface, making it an excellent choice for boat builders seeking to optimize the performance and longevity of their vessels.

| Characteristics | Values |

|---|---|

| Strength | Fiberglass adds significant strength to the boat's floor, making it more rigid and durable. It can withstand heavy loads and provide structural integrity. |

| Impact Resistance | The material is highly impact-resistant, protecting the floor from damage caused by waves, anchors, or other marine activities. |

| Corrosion Resistance | Fiberglass is resistant to corrosion, ensuring the boat's floor remains intact and functional over time, even in harsh marine environments. |

| Lightweight | Despite its strength, fiberglass is relatively lightweight, contributing to the overall buoyancy and ease of handling of the boat. |

| Customization | It can be easily molded and shaped to fit various boat designs, allowing for creative and unique floor patterns. |

| Maintenance | Fiberglass floors require minimal maintenance, as they are resistant to stains, scratches, and UV damage. |

| Cost-Effective | While offering excellent performance, fiberglass is often a cost-effective choice for boat flooring, especially when compared to other materials. |

| Longevity | With proper care, fiberglass floors can last for many years, providing a reliable and long-lasting solution for boat owners. |

What You'll Learn

- Fiberglass Reinforcement: How fiberglass adds strength and durability to wooden boat floors

- Structural Integrity: The role of fiberglass in maintaining the structural integrity of the boat

- Impact Resistance: Fiberglass's ability to enhance the boat's resistance to impact and damage

- Waterproofing: Fiberglass's contribution to waterproofing the wooden boat floor

- Weight Distribution: Fiberglass's role in distributing weight evenly, reducing stress on the wooden structure

Fiberglass Reinforcement: How fiberglass adds strength and durability to wooden boat floors

Fiberglass, a composite material made from woven glass fibers, has become an essential component in the construction and reinforcement of wooden boat floors. When applied to wooden structures, fiberglass provides a range of benefits that significantly enhance the overall strength and durability of the boat's floor. This reinforcement technique has been a game-changer for boat builders and enthusiasts, offering a cost-effective and efficient way to improve the structural integrity of wooden boats.

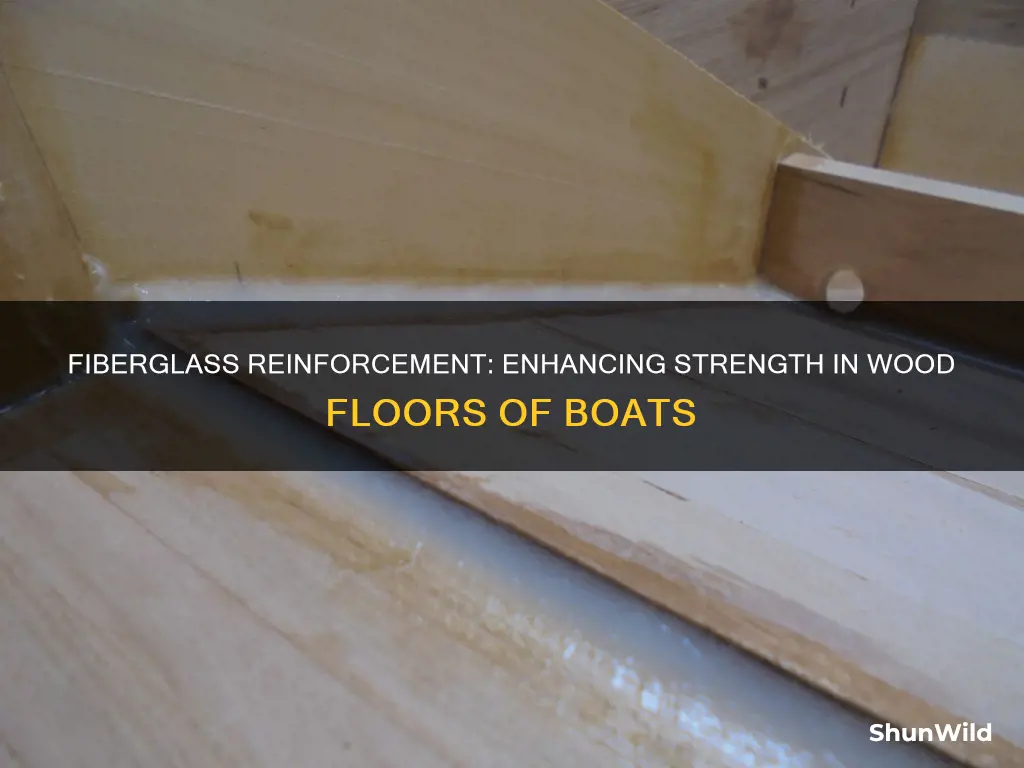

The process of fiberglass reinforcement involves laying a layer or multiple layers of fiberglass cloth or mat over the wooden floor, ensuring complete coverage. This is then followed by a layer of resin, which acts as a binding agent, creating a strong and lightweight composite. The resin hardens, forming a rigid and durable layer that bonds with the wood, providing exceptional strength. This method is particularly useful for wooden boats as it offers a way to reinforce the floor without adding excessive weight, which is crucial for maintaining the boat's buoyancy and overall performance.

One of the key advantages of using fiberglass for wooden boat floors is its ability to distribute stress evenly. When a boat is in motion, the floor experiences various stresses and impacts. Fiberglass, with its high tensile strength, can effectively absorb and transfer these stresses, preventing the wood from warping, cracking, or failing. This even distribution of stress ensures that the boat's floor remains sturdy and reliable, even under demanding conditions.

Furthermore, fiberglass provides excellent resistance to water and moisture, which is vital for boat floors. Wooden boats are susceptible to water damage, and the introduction of fiberglass creates a protective barrier, preventing water absorption and the subsequent deterioration of the wood. This resistance to moisture also makes the boat's interior more comfortable and less prone to mold and mildew, ensuring a healthier and more pleasant environment for passengers and crew.

In summary, fiberglass reinforcement is a powerful technique to enhance the performance and longevity of wooden boat floors. Its ability to provide strength, distribute stress, and resist moisture makes it an indispensable tool for boat builders and owners. By incorporating fiberglass, wooden boats can achieve a higher level of durability and safety, ensuring enjoyable and worry-free boating experiences. This method of reinforcement showcases the innovative ways in which modern materials can be utilized to preserve and improve traditional boat-building practices.

The Trashmen's Boat: A Mystery Unveiled

You may want to see also

Structural Integrity: The role of fiberglass in maintaining the structural integrity of the boat

Fiberglass is a versatile material that plays a crucial role in enhancing the structural integrity of boats, especially those with wooden flooring. When used in boat construction, fiberglass provides several key benefits that contribute to the overall strength and durability of the vessel.

One of the primary advantages of incorporating fiberglass into boat design is its ability to reinforce the wooden structure. Wood, while a natural and aesthetically pleasing material, can be susceptible to rot, insect damage, and water absorption. By applying a layer of fiberglass over the wooden floor, boat builders create a protective barrier that shields the wood from these potential issues. This protective layer not only prevents water absorption but also adds an extra layer of strength, making the boat more resistant to structural damage.

The structural integrity of a boat heavily relies on its ability to withstand various forces, such as impact, pressure, and vibrations. Fiberglass, with its high tensile strength and flexibility, excels in distributing these forces evenly across the boat's structure. This even distribution of stress helps prevent localized damage and ensures that the boat remains stable and secure, even in challenging marine environments.

In the context of wooden-floored boats, fiberglass can be applied in various forms, such as laminates, composites, or as a reinforcement layer within the boat's hull. When used as a laminate, fiberglass creates a smooth, durable surface that not only enhances the boat's appearance but also provides an additional layer of protection against wear and tear. Composites, on the other hand, offer a more integrated approach, combining fiberglass with other materials to create a lightweight yet robust structure.

Furthermore, the use of fiberglass in boat construction allows for precise control over the boat's shape and design. Boat builders can manipulate the fiberglass material to create intricate contours, ensuring a seamless fit and a visually appealing exterior. This level of customization, combined with the material's strength, results in a boat that not only looks good but also performs exceptionally well in various water conditions.

Paddle Boating in Cleveland: How Much Does It Cost?

You may want to see also

Impact Resistance: Fiberglass's ability to enhance the boat's resistance to impact and damage

Fiberglass is a versatile material that significantly contributes to the impact resistance of boats, particularly those with 3/4-inch wood flooring. When incorporated into boat construction, fiberglass provides a robust and durable layer that enhances the overall structural integrity. Its ability to absorb and distribute impact forces is a key advantage, making it an excellent choice for boat builders aiming to create a sturdy and long-lasting vessel.

The impact resistance of fiberglass is attributed to its composite nature, combining glass fibers with a resin matrix. This composite structure allows for the efficient transfer of energy, preventing localized damage and minimizing the risk of structural failure. When a boat encounters an impact, such as a collision with an object or a sudden jolt, the fiberglass layer acts as a protective shield, absorbing and dispersing the force across a larger area. This feature is especially crucial for boats with wooden floors, as wood is more susceptible to localized damage and can crack or split under impact.

In the context of boat flooring, the impact resistance of fiberglass becomes even more apparent. The material's flexibility and strength enable it to withstand the repetitive stresses and impacts that occur during normal use. For example, when a boat is navigated through rough waters or experiences sudden movements, the fiberglass floor provides a stable and impact-resistant surface. This is particularly beneficial for activities like fishing, where the boat may encounter various obstacles or experience sudden accelerations and decelerations.

Furthermore, the impact resistance of fiberglass extends to its ability to protect the underlying wooden structure. By providing a robust outer layer, fiberglass shields the wood from direct impact, reducing the likelihood of damage. This is especially important in areas prone to marine growth and corrosion, as fiberglass can act as a barrier, preventing direct exposure to harsh marine environments. Over time, this protective layer can significantly extend the lifespan of the boat, ensuring that the wooden floor remains intact and functional.

In summary, fiberglass's impact resistance is a critical factor in enhancing the overall safety and durability of boats with 3/4-inch wood flooring. Its ability to absorb and distribute impact forces, combined with its protective nature, ensures that the boat's structure remains intact and functional. Boat owners and builders can benefit from this material's properties, creating vessels that are not only strong but also capable of withstanding the challenges of marine environments.

Unraveling the Power of Dual Propellers: How They Boost Boat Performance

You may want to see also

Waterproofing: Fiberglass's contribution to waterproofing the wooden boat floor

Fiberglass is an excellent material for enhancing the waterproofing capabilities of wooden boat floors. When applied to the wooden substrate, it creates a robust and durable barrier that significantly reduces the risk of water penetration and damage. The process involves carefully laying up layers of fiberglass cloth or mat, often combined with a resin system, directly onto the wooden floor. This construction method provides several key benefits for waterproofing.

Firstly, the fiberglass layer acts as a physical barrier, preventing water from seeping through the wood. It is an effective moisture barrier, especially when used in conjunction with a suitable resin that fills the voids and capillaries in the wood, further enhancing its water-resistant properties. This is particularly important in boat construction, where the floor is constantly exposed to moisture from the surrounding water and the bilge area.

The application of fiberglass also contributes to the overall structural integrity of the boat floor. By reinforcing the wood with fiberglass, the floor becomes more rigid and less prone to warping or cracking. This added strength is crucial for the long-term durability of the boat, ensuring that the floor remains intact and functional even after prolonged exposure to water and the marine environment. The fiberglass layer can be tailored to provide the necessary thickness and strength, making it an ideal choice for reinforcing wooden boat floors.

In addition, the use of fiberglass allows for the creation of a smooth and seamless surface on the wooden boat floor. This is essential for maintaining a clean and professional appearance, especially in areas that are visible to passengers or crew. The fiberglass can be shaped and molded to follow the contours of the wood, ensuring a tight and secure bond, which further enhances its waterproofing performance.

When applying fiberglass to the boat floor, it is crucial to follow a systematic approach. The process typically involves preparing the wood surface, laying up the fiberglass layers, and carefully applying the resin to ensure proper bonding. Proper preparation of the wood, including sanding and priming, is essential to create a suitable surface for the fiberglass to adhere to. This meticulous process ensures that the fiberglass and wood work together harmoniously, providing an effective and long-lasting waterproofing solution for the wooden boat floor.

Running Wire to a Boat Battery: A Step-by-Step Guide

You may want to see also

Weight Distribution: Fiberglass's role in distributing weight evenly, reducing stress on the wooden structure

Fiberglass, when used in the construction of a 3/4-inch wooden flooring boat, plays a crucial role in weight distribution, which is essential for the boat's structural integrity and overall performance. The primary function of fiberglass in this context is to provide a lightweight yet strong reinforcement system that helps distribute the boat's weight evenly across its structure. This even distribution is vital to ensure that the wooden components, particularly the floor, do not bear excessive stress, which could lead to structural failure or damage over time.

In a boat, the floor is a critical element that supports the weight of the vessel, its contents, and passengers. When a boat is in motion, especially in rough waters, the floor must withstand various stresses, including compression, tension, and shear forces. Fiberglass, being a composite material, offers a unique advantage in this regard. It can be strategically placed and molded to follow the natural curves and contours of the wooden floor, creating a seamless and reinforced structure. This design approach ensures that the weight is distributed more efficiently, reducing the risk of localized stress concentrations that could compromise the boat's integrity.

The process of incorporating fiberglass involves carefully laying the material over the wooden floor, often using a gelcoat or a specialized adhesive to secure it in place. This application method allows for precise control over the thickness and coverage of the fiberglass layer, ensuring that the weight is distributed uniformly. By doing so, the fiberglass acts as a protective barrier, preventing the wooden floor from bearing the full weight directly, which could lead to warping, cracking, or even structural failure.

Furthermore, fiberglass provides a degree of flexibility, allowing it to absorb and redistribute minor impacts or vibrations that occur during the boat's operation. This flexibility is particularly beneficial in reducing the overall stress on the wooden structure, as it can accommodate minor movements without causing damage. The combination of fiberglass and wood in this manner creates a robust and durable boat floor that can withstand the rigors of marine environments.

In summary, the use of fiberglass in 3/4-inch wooden flooring boats is a strategic design choice that significantly contributes to weight distribution. By evenly spreading the load, fiberglass reduces the stress on the wooden structure, ensuring the boat's longevity and safety. This application of composite materials showcases how innovative construction techniques can enhance the performance and durability of marine vessels.

Repairing a Boat Cover: Patching Holes, Easy Fixes

You may want to see also

Frequently asked questions

Yes, fiberglass can significantly enhance the structural integrity and strength of a 3/4-inch wood floor in a boat. When applied as a layer or several layers of fabric, fiberglass provides excellent reinforcement, making the floor more robust and durable. It helps distribute stress evenly, preventing the wood from warping or cracking, especially in areas prone to impact or heavy foot traffic.

Fiberglass offers superior durability to boat floors due to its impact resistance and ability to withstand harsh marine environments. The resin and fiberglass combination creates a rigid and lightweight structure that can endure the constant movement and vibrations experienced in boats. This makes the floor less susceptible to damage from accidental bumps, scratches, or even minor collisions.

Absolutely! Fiberglass is an ideal material for repairing damaged wood floors in boats. It can be used to fill in holes, cracks, or any other imperfections caused by wear and tear. By applying a layer of fiberglass resin and cloth, the repair area is reinforced, ensuring a seamless and strong finish. This method is commonly used to restore the structural integrity of boat floors while maintaining their aesthetic appeal.

While fiberglass offers numerous benefits, there are a few considerations. Fiberglass can be heavier than wood, so it might add some extra weight to the boat. However, this is often mitigated by the overall strength and durability it provides. Additionally, the installation process requires skill and precision to ensure proper bonding and a smooth finish. Proper ventilation during the resin application is also essential to avoid inhaling fumes.