Electrolysis is a process that occurs when an electrical current passes through water, resulting in a chemical reaction. This reaction can cause corrosion in metal components, including those on boats. While electrolysis can occur in any type of water, saltwater is a more conductive liquid than freshwater due to its chemical composition, making it a greater facilitator of the electrolysis process.

Electrolysis can affect any kind of boat, including those made of aluminium, and can lead to deterioration and damage if preventative measures are not taken. This is because aluminium is a chemically active metal that is particularly susceptible to corrosion.

To prevent electrolysis and protect their boats, owners can employ several strategies, including the use of sacrificial anodes, corrosion-protection paint, and regular maintenance of electrical systems.

What You'll Learn

Electrolysis vs galvanic corrosion

Electrolysis and galvanic corrosion are two distinct processes that can cause aluminium boats to deteriorate. While both are driven by chemical reactions, there are key differences between them.

Electrolysis occurs when an electrical current passes through water, causing a chemical reaction. In the context of boating, this reaction occurs between two dissimilar metals. The electrical current strips away one metal and deposits it on the other. For example, if an aluminium boat has a zinc propeller, the current will strip away electrons from the zinc and deposit them on the aluminium hull, which attracts the current. This process causes corrosion and can damage the metal parts of the boat over time.

On the other hand, galvanic corrosion is a natural chemical reaction that occurs when two different metals come into direct contact with each other in an electrolyte, such as saltwater. In this process, one metal will be more chemically active than the other, and they will exchange electrons. This type of corrosion can only occur in saltwater, as freshwater does not allow for the exchange of electrons between metals.

To prevent electrolysis on aluminium boats, it is crucial to address any electrical currents in the water. This may involve checking for faulty wiring or inadequate electrical boxes, which can send stray currents through the water. Additionally, sacrificial anodes made of zinc, magnesium, or aluminium can be attached to the bottom of the boat. These anodes are more chemically active and will corrode instead of the boat's metal components.

To mitigate galvanic corrosion, measures such as painting or coating metal surfaces, using corrosion inhibitors, and ensuring proper earthing of onboard equipment can be implemented.

While both electrolysis and galvanic corrosion can cause deterioration in aluminium boats, understanding their unique characteristics is essential for effective prevention and protection.

Starting a Boat Dealer: Essential Steps to Take

You may want to see also

How to prevent galvanic corrosion

Aluminium boats are susceptible to galvanic corrosion, a process that occurs when two dissimilar metals are connected by an electrolyte, enabling the movement of electrical current. In this case, saltwater acts as the electrolyte, and the presence of other metals in contact with the boat creates the perfect environment for corrosion to occur.

To prevent galvanic corrosion on an aluminium boat, you can take the following measures:

Use Sacrificial Anodes

Install sacrificial anodes made of zinc, magnesium, or aluminium, depending on the water type. These anodes will corrode instead of your boat, protecting it from corrosion. Ensure you select the appropriate anode material for your water type (zinc or aluminium for saltwater, and magnesium for freshwater). Regularly inspect and replace the anodes as needed.

Paint and Coatings

Apply a coat of protective paint designed for aluminium to metal surfaces. This will create a barrier against chemical reactions leading to corrosion. Additionally, use only paint, lubricants, and grease designed for use with aluminium.

Maintenance and Inspection

- Keep the inside of the boat dry.

- Avoid contact with other metals, including bolts and hardware. Use nylon washers to separate dissimilar metals.

- Rinse the boat with freshwater after use in saltwater and dry it off.

- Repair any cracks or scratches that expose the bare aluminium.

- Check your wiring for any loose or frayed wires that may be touching the hull.

- Avoid using lubricants containing graphite, as it can contribute to galvanic corrosion.

Other Precautions

- If your boat is not in use, disconnect the battery to prevent any stray currents from leaving the boat.

- Avoid leaving metal objects, such as anchors or loose metal parts, in the water when the boat is not in use.

- If your boat is docked in an area with potential electrical currents, consider using a zinc fish to protect the metal components.

- Use floating boat lifts to keep your boat out of the water when not in use, reducing the likelihood of corrosion.

Exploring Gig Harbor: A Quick Boat Ride from Seattle

You may want to see also

How to prevent electrolysis

Electrolysis can affect any kind of boat in any kind of water. It occurs when an electrical current passes through water, causing a chemical reaction. This reaction causes corrosion, which damages the metal parts of the boat. While electrolysis can occur in any water, saltwater speeds up the process due to its higher conductivity.

Use Anodes

Anodes are pieces of metal, usually made of zinc, magnesium, or aluminum, that are attached to the bottom of the boat. They work by attracting the electrical current and corroding instead of the boat's metal components. The type of anode you use depends on the water you're boating in. Use zinc or aluminum anodes in saltwater, as they protect better against its high conductivity. Use magnesium anodes in freshwater, as they dissolve too quickly in saltwater.

Paint

Painting the boat with a protective coat can prevent electrolysis by creating a barrier between the boat and the water. It's important to note that you should only paint the areas of the boat that are above the waterline. Keeping the parts of the boat that are submerged bare allows the aluminum to form a protective layer of aluminum oxide.

Keep the Boat Dry

Keeping the inside of the boat dry is crucial in preventing electrolysis. If water is present inside the boat, the chemical reaction can occur and start to corrode the metal components.

Use Products Made for Aluminum Boats

When applying any materials to your aluminum boat, such as paint, lubricants, or grease, ensure that they are specifically designed for use with aluminum.

Maintain the Bottom Paint

Keep an eye out for any chips or scratches in the bottom paint, as these spots are more vulnerable to corrosion. If boating in saltwater, try to put the boat on a lift when not in use and hose it down with freshwater to remove any salt that could cause corrosion.

Avoid Contact with Other Metals

Avoid contact between the aluminum boat and other metals, such as bolts or hardware. You can use nylon washers to keep the heads of bolts from touching the aluminum. Also, keep metal objects like lures, hooks, and anchors off the bottom of the boat and out of the bilge.

Disconnect the Battery

Disconnecting the battery when the boat is not in use can help prevent electrolysis. This breaks the circuit and stops any electrical current from passing through the water and corroding the metal components.

Boat Requirements in North Carolina: What You Need to Know

You may want to see also

How to identify electrolysis

Electrolysis is a process that can affect any kind of boat in any kind of water. It occurs when an electrical current passes through water, causing a chemical reaction with the metal components of a boat. While it is a rare problem in freshwater, saltwater speeds up the process due to its higher conductivity.

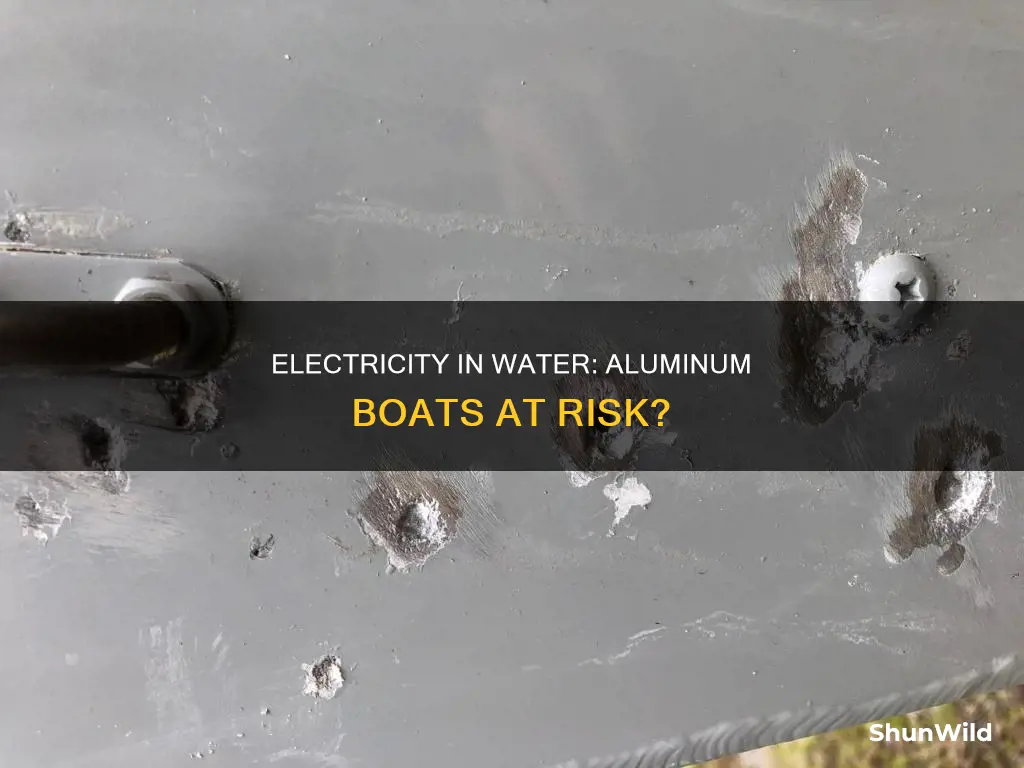

- Visual Inspection: Look for signs of corrosion or deterioration on the metal components of your boat. Electrolysis causes the metal to "eat away" or strip away, which can be visible over time.

- Electrical Current Source: Electrolysis occurs due to electrical currents in the water, which can be caused by faulty wiring or inadequately wired electrical boxes. If you suspect electrical issues with your boat or nearby boats, it could indicate a risk of electrolysis.

- Water Type: Electrolysis can occur in any water type but is more common and faster in saltwater due to its higher conductivity. Therefore, if your boat is frequently used in saltwater, it is more susceptible to electrolysis.

- Metal Composition: The process of electrolysis occurs between two dissimilar metals. For example, if your boat has an aluminum hull and a zinc propeller, electrolysis can occur as zinc has a higher electrolytic voltage.

- Corrosion Protection: If your boat is equipped with corrosion protection measures such as anti-corrosion paint or anodes, it may indicate that electrolysis is a concern. These measures are designed to prevent or slow down the effects of electrolysis.

- Stray Currents: If you notice stray electrical currents in the water around your boat, it could be a sign of electrolysis. These currents can be caused by faulty wiring or other boats with electrical issues.

- Neighbouring Boats: Electrolysis can occur between two boats in close proximity, especially if they have different metal compositions. If you notice any signs of corrosion on neighbouring boats, it may be worth inspecting your own boat for similar issues.

Remember that electrolysis can cause significant damage to your boat over time, so it is important to be vigilant and take preventive measures. Regular inspections and maintenance of your boat's electrical systems and metal components are crucial to mitigating the risks associated with electrolysis.

Transferring Boat Ownership: Florida's Guide to Title Transfers

You may want to see also

How to fix an electrolysis-damaged boat

Electrolysis is a process that occurs when an electrical current passes through water, causing a chemical reaction. This reaction can cause severe damage to boats, especially those made of aluminum. While it may not be possible to completely reverse the damage caused by electrolysis, there are several repair and prevention methods that can be implemented to slow down the process and protect the boat from further deterioration. Here are some detailed instructions on how to fix and prevent electrolysis damage on an aluminum boat:

Identify the Source of Electrolysis:

Start by identifying the source of the electrical current causing electrolysis. This could be due to faulty wiring, a bad shore power ground lead, or inadequate electrical boxes. It is important to consult with a qualified marine electrician to diagnose and fix the electrical issues.

Use Sacrificial Anodes:

Sacrificial anodes are made of zinc, magnesium, or aluminum and are designed to be sacrificed to electrolysis instead of the other metal components on your boat. These anodes should be attached to the bottom of the boat and engine. In saltwater or brackish water, use zinc or aluminum anodes, while in freshwater, magnesium anodes are more suitable. Ensure that the anodes are firmly in place and left bare, as painting them will render them ineffective.

Apply Protective Paint:

Coat the aluminum surfaces of your boat with a good protective paint, such as a corrosion-resistant paint. This will create a barrier against the chemical reactions causing galvanic corrosion. Apply the paint at least up to the waterline along the sides of the boat. However, avoid painting over any anodes as this will hinder their effectiveness.

Maintain the Boat Regularly:

Regular maintenance is crucial to prevent further damage. Keep the inside of the boat dry, as moisture can trigger the chemical reaction leading to corrosion. If your boat has been in saltwater, rinse it thoroughly with freshwater and dry it off afterward. Additionally, inspect and clean the anodes regularly to ensure they are free of grime and buildup, allowing them to function effectively.

Avoid Mixing Metals:

To minimize the risk of electrolysis, avoid mixing different metals on your boat. Use aluminum components with aluminum fittings, and avoid using aluminum nuts on steel bolts, for example. This will reduce the likelihood of facilitating the chemical reaction that leads to corrosion.

Disconnect Power When Not in Use:

When your boat is not in use, disconnect the power to shut down magnetic fields and prevent the occurrence of the chemical reaction. This will also prevent any stray currents from leaving the boat and causing further damage.

Conduct Hull Reference Tests:

Consider conducting hull reference tests to measure the ambient voltage near your boat. These tests will help determine the number of anodes required to protect your boat adequately. Consult with your local marina or a qualified marine electrician to perform these tests.

Use Zinc Fish:

If your marina is known for faulty wiring, consider using zinc fish, which are placed in the water around your boat. They are a more affordable option than constantly replacing anodes, and they will help protect your hull and propeller shaft from corrosion.

Choose the Right Products:

When applying any materials to your aluminum boat, such as paint, lubricants, or grease, always opt for products specifically designed for use with aluminum. This is important because aluminum requires different care compared to other materials like fiberglass.

Keep the Boat on a Lift:

If possible, keep your boat on a lift when not in use, especially if it is in saltwater. This will help minimize the boat's exposure to corrosive elements and reduce the risk of electrolysis.

Isolate the Boat's Electrical System:

If your boat is docked at a marina with shore power, connect it to an isolation transformer. This will help prolong the life of your anodes and prevent corrosion by isolating the boat's electrical system from other vessels.

Avoid Contact with Other Metals:

Avoid contact between the aluminum surfaces of your boat and other metals, including bolts, hardware, lures, and hooks. Use nylon washers to keep the heads of bolts from touching the aluminum. This will reduce the likelihood of creating a chemical reaction that leads to corrosion.

Monitor and Replace Anodes:

Regularly monitor the condition of your anodes and replace them as necessary. If they have degraded to half their original size before the end of the boating season, adjust the number of anodes accordingly. Remember that anodes are sacrificial and will weaken over time to protect the more critical parts of your boat.

Consult Professionals:

Finally, if you are unsure about the extent of the damage or the best course of action, consult with boat maintenance professionals or marine electricians. They can provide expert advice and guidance tailored to your specific situation.

Remember, while these measures can help slow down the effects of electrolysis and prevent further damage, the best way to protect your boat is to take preventive actions before any damage occurs. Always be vigilant and proactive in maintaining your boat to ensure its longevity.

Boat Insurance in Michigan: What's the Law?

You may want to see also

Frequently asked questions

Electrolysis is the movement of electric current through a liquid, causing chemical decomposition and a reaction with metal components in the liquid.

Electrolysis causes corrosion on aluminum boats, which can lead to significant damage over time as the electrical current "eats away" at the metal.

Galvanic corrosion is a specific type of corrosion that occurs only in saltwater due to the presence of an electrolyte (salt). Electrolysis can occur in any type of water and does not require an electrolyte.

You can use anodes made of zinc, magnesium, or aluminum, depending on the water type. These sacrificial metals will corrode instead of the important metals in your boat. Additionally, painting over aluminum parts with corrosion protection paint and ensuring proper wiring and power management can help prevent electrolysis.

Look for corrosion or damage on metal components, especially in areas where different metals are in contact. Regularly inspect and maintain your boat, including checking for any faulty wiring or electrical boxes that may be sending stray electrical currents into the water.