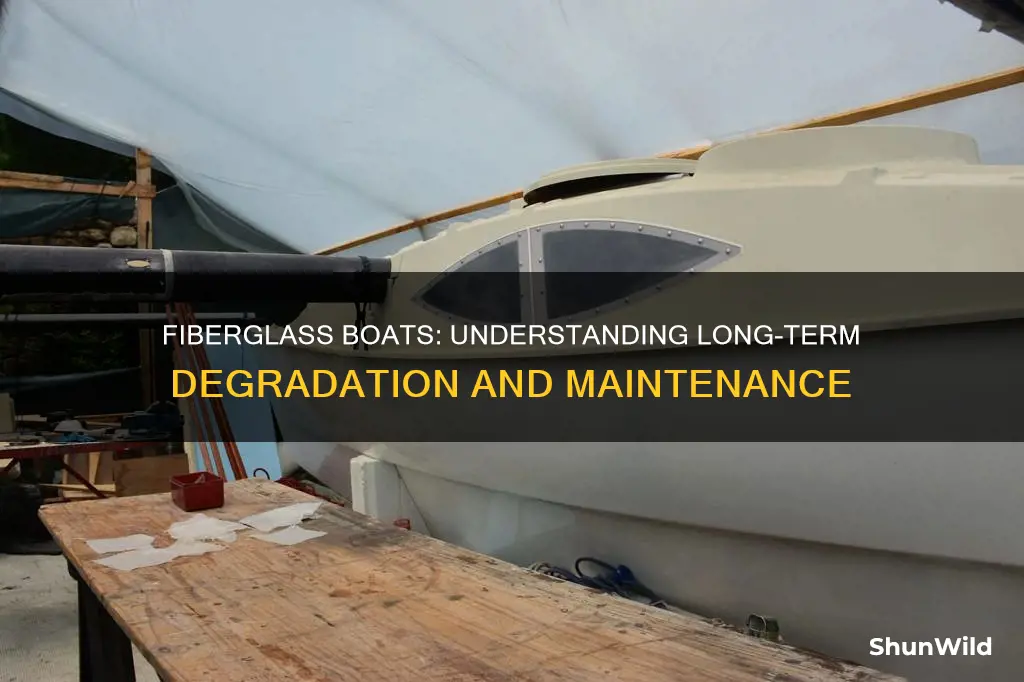

Fiberglass boats, known for their durability and sleek design, are a popular choice for boating enthusiasts. However, like any material, they are subject to the natural process of aging and degradation over time. This paragraph will explore the factors that contribute to the degradation of fiberglass boats and discuss the potential impact on their performance and appearance. By understanding these aspects, boat owners can make informed decisions about maintenance and care to ensure the longevity of their vessels.

| Characteristics | Values |

|---|---|

| Material Degradation | Fiberglass boats can experience degradation over time due to exposure to sunlight, UV rays, and harsh weather conditions. The composite material can become brittle and discolored. |

| Aging and Maintenance | Regular maintenance is crucial to prevent degradation. This includes cleaning, waxing, and applying protective coatings to preserve the boat's condition. |

| Environmental Factors | Prolonged exposure to saltwater, chemicals, and pollutants can accelerate degradation. Proper storage and maintenance in harsh environments are essential. |

| Structural Integrity | While degradation can affect appearance, it may not always compromise structural integrity. However, cracks, delamination, and water infiltration should be addressed promptly. |

| Longevity | With proper care, fiberglass boats can last for decades. Regular inspections and timely repairs can significantly extend their lifespan. |

| Resale Value | Boats in good condition can retain their value over time, but degradation may impact resale price. Well-maintained boats may have a higher resale value. |

| Upkeep and Repairs | Regular upkeep, including repainting, replacing damaged parts, and addressing issues promptly, can help maintain the boat's condition and prevent further degradation. |

What You'll Learn

- Fiberglass Degradation Factors: UV rays, temperature changes, and water exposure accelerate degradation

- Boat Age and Condition: Older boats may show more signs of degradation

- Maintenance and Care: Regular maintenance can slow down the degradation process

- Environmental Impact: Pollution and climate change affect fiberglass degradation

- Long-Term Performance: Proper care ensures boat longevity and performance

Fiberglass Degradation Factors: UV rays, temperature changes, and water exposure accelerate degradation

The longevity of a fiberglass boat is significantly influenced by various environmental factors, with UV rays, temperature fluctuations, and water exposure playing pivotal roles in its degradation process. These elements can accelerate the breakdown of the boat's composite structure, leading to potential structural issues and a decline in its overall performance and appearance.

UV Rays: Sunlight, particularly the ultraviolet (UV) component, is a potent catalyst for degradation. UV rays can cause a chemical reaction in the fiberglass, leading to a process known as photo-oxidation. This reaction results in the breakdown of the polymer chains within the fiberglass, causing it to become brittle and more susceptible to cracking and chipping. Over time, this can compromise the boat's structural integrity, especially in areas exposed to direct sunlight, such as the deck and sides.

Temperature Changes: Extreme temperature variations can also contribute to the degradation of fiberglass. When exposed to rapid temperature fluctuations, the material can experience thermal shock, which causes it to expand and contract rapidly. This repetitive stress can lead to micro-cracks in the fiberglass, making it more prone to damage. Additionally, high temperatures can accelerate the breakdown of adhesives and resins, further compromising the boat's structure.

Water Exposure: Water is a critical factor in the degradation process, especially when it comes into contact with the boat's interior. Fiberglass is not inherently waterproof, and prolonged exposure to moisture can lead to delamination, where the layers of the composite separate. This often occurs in areas with poor ventilation, such as the bilge and below deck compartments. Water absorption can also cause the fiberglass to become heavy and more susceptible to structural failure.

The cumulative effect of these factors can significantly impact the boat's performance and appearance. UV rays, temperature changes, and water exposure work in conjunction to accelerate the natural aging process of the fiberglass, leading to a faster degradation rate. Regular maintenance, such as applying protective coatings and ensuring proper ventilation, can help mitigate these issues and extend the lifespan of the boat. Understanding these degradation factors is essential for boat owners and manufacturers to implement appropriate measures to preserve the integrity and longevity of fiberglass boats.

Grey Boat Shoes: Style Guide for Versatile Footwear

You may want to see also

Boat Age and Condition: Older boats may show more signs of degradation

Aging is an inevitable process for any boat, and older vessels, especially those constructed with fiberglass, may exhibit more visible signs of degradation over time. Fiberglass, while a durable material, can still be susceptible to various environmental factors that contribute to its breakdown. One of the primary concerns for older fiberglass boats is the potential for gelcoat fading and chalking. The gelcoat, a protective layer applied to the fiberglass, can lose its luster and become chalky due to prolonged exposure to sunlight, UV rays, and harsh weather conditions. This degradation not only affects the boat's aesthetic appeal but can also lead to further issues.

As the gelcoat deteriorates, it may become more susceptible to scratches, chips, and other forms of damage. Older boats might also experience issues with the underlying fiberglass structure. Over time, the fiberglass can become brittle and more prone to cracking or delamination, especially in areas where the material was joined or where stress concentrations exist. These structural weaknesses can compromise the boat's integrity and safety, making regular inspections and maintenance crucial for older vessels.

Another aspect to consider is the boat's hardware and fittings. Older boats may have corroded or worn-out hardware, such as fasteners, hinges, or even engine components. Rust and corrosion can weaken these parts, leading to potential failures and safety hazards. Additionally, the boat's interior may show signs of wear and tear, with upholstery fading, tearing, or becoming stained, and interior finishes may lose their original luster.

To mitigate these issues, boat owners should conduct regular inspections and maintenance. This includes checking for any signs of gelcoat damage, such as fading or chalking, and addressing them promptly. Regular cleaning and waxing of the gelcoat can help preserve its appearance and protect it from further degradation. Additionally, inspecting the boat's structure for any cracks or signs of delamination and ensuring that all hardware is in good condition are essential tasks for maintaining an older fiberglass boat.

In summary, older boats, particularly those made of fiberglass, are more likely to exhibit signs of degradation. Understanding the potential issues, such as gelcoat fading, structural weaknesses, and hardware corrosion, allows boat owners to take proactive measures to preserve their vessels. Regular maintenance, inspections, and addressing any issues promptly can help ensure the longevity and safety of older boats, allowing them to continue providing enjoyable experiences on the water.

Challenging the Boat Caption: Navigating Unconventional Waters

You may want to see also

Maintenance and Care: Regular maintenance can slow down the degradation process

Regular maintenance is crucial for fiberglass boats to ensure longevity and preserve their structural integrity. The natural degradation of fiberglass, while inevitable, can be significantly slowed down with proper care and attention. Here's a comprehensive guide on how regular maintenance can make a difference:

Cleaning and Protection: Start by keeping your boat clean. Regular washing with a mild detergent and soft brush helps remove dirt, grime, and marine growth that can accumulate over time. Pay attention to hard-to-reach areas, such as the hull, transom, and waterline, as these areas are more susceptible to damage and growth. After cleaning, consider applying a marine-grade wax or protective coating to the fiberglass surface. This protective layer acts as a barrier, preventing UV rays, saltwater, and other environmental factors from directly interacting with the fibers, thus slowing down degradation.

Inspect and Repair: Routine inspections are essential. Check for any signs of damage, such as small cracks, chips, or delamination. These issues, if left unattended, can worsen over time and lead to more significant structural problems. For minor repairs, fiberglass repair kits are readily available and can be used to fill in small holes or cracks. For more extensive damage, it is advisable to seek professional help to ensure the repair is done correctly and safely. Regularly inspecting and addressing any issues will prevent further degradation and maintain the boat's structural integrity.

Antifouling and Bottom Paint: Marine growth, such as barnacles and algae, can be detrimental to a fiberglass boat's performance and appearance. Regular antifouling treatments and bottom paints are essential to keep the hull clean and protect the fiberglass. Choose an antifouling paint suitable for fiberglass and apply it according to the manufacturer's instructions. This process should be done annually or as recommended by the boat's manufacturer to ensure optimal protection.

Interior Care: The interior of the boat also requires maintenance. Regularly clean and vacuum the cabin, head, and any other enclosed spaces. Use marine-grade cleaning products to remove stains and odors without damaging the fiberglass or other materials. Check for any signs of water damage or mold, which can be a result of poor drainage or leaks. Addressing these issues promptly will prevent further degradation and maintain a healthy environment for the boat's occupants.

Mooring and Storage: Proper mooring techniques and storage practices are vital for fiberglass boat maintenance. When mooring, ensure the boat is positioned in a way that minimizes exposure to harsh weather conditions and UV rays. Consider using a boat cover to provide an extra layer of protection during extended periods of storage. Regularly inspect the cover for tears or damage and replace it if necessary. Proper storage will help preserve the boat's condition and slow down the natural degradation process.

By implementing these maintenance practices, boat owners can significantly extend the lifespan of their fiberglass vessels and maintain their value over time. Regular care and attention are key to ensuring the boat remains in optimal condition, providing a safe and enjoyable boating experience.

Exploring the Colgate 26: A Versatile Cruiser and Racer

You may want to see also

Environmental Impact: Pollution and climate change affect fiberglass degradation

The environmental impact of fiberglass degradation is a critical aspect to consider when examining the long-term sustainability of this popular boat material. Fiberglass, while durable, is not immune to the effects of pollution and climate change, which can lead to various forms of degradation over time.

One significant factor is the presence of pollutants in the environment, such as industrial emissions and chemical runoff. These pollutants can infiltrate the fiberglass structure, causing a range of issues. For instance, acid rain, formed by sulfur dioxide and nitrogen oxide emissions, can corrode the glass fibers and the resin matrix, leading to a loss of structural integrity. This corrosion process can weaken the boat's hull and components, making it more susceptible to damage and potentially rendering it unseaworthy. Moreover, pollutants like heavy metals and volatile organic compounds (VOCs) can leach into the water, posing risks to marine ecosystems and potentially affecting the health of those who use the boat.

Climate change also plays a significant role in the degradation of fiberglass boats. Rising sea temperatures can cause thermal expansion and contraction of the materials, leading to stress and potential cracking. This is particularly concerning for older boats, as the repeated expansion and contraction can accelerate the aging process of the fiberglass. Additionally, increased ocean acidification due to higher carbon dioxide levels in the atmosphere can further corrode the glass fibers, making the boat's structure more fragile.

The impact of these environmental factors is not just limited to the boat's performance but also has broader ecological consequences. As fiberglass degrades, it can release microplastics and other hazardous substances into the water, contributing to marine pollution. These microplastics can be ingested by marine life, leading to potential harm to the entire food chain. Furthermore, the degradation process can also release volatile organic compounds, which contribute to air pollution and have adverse effects on human health.

Addressing the environmental impact of fiberglass degradation requires a multi-faceted approach. Boat owners and manufacturers can contribute by adopting sustainable practices, such as using eco-friendly resins and coatings that are less susceptible to corrosion. Regular maintenance and inspections can help identify and mitigate degradation issues early on. Additionally, raising awareness about the environmental implications of fiberglass degradation can encourage the development of more sustainable boat materials and promote responsible disposal practices.

Mastering Boat Sailing with Fluctuating Currents: Miles Traveled

You may want to see also

Long-Term Performance: Proper care ensures boat longevity and performance

The longevity and performance of a fiberglass boat are significantly influenced by proper maintenance and care. Over time, even with regular use, a fiberglass vessel can experience degradation due to various factors, including exposure to the elements, UV radiation, and chemical pollutants. However, with the right maintenance routine, you can ensure that your boat remains in optimal condition, providing years of enjoyable use.

One of the most critical aspects of long-term care is regular cleaning and maintenance. Fiberglass is susceptible to staining and discoloration, especially in areas exposed to sunlight. It is essential to clean the boat regularly to remove dirt, grime, and any organic matter that can accumulate. Use a mild detergent and a soft brush to clean the surface, ensuring you don't scratch the gelcoat. For more stubborn stains, consider using a specialized fiberglass cleaner, but always test it in an inconspicuous area first.

Protection from the sun is another key factor in preserving your boat's integrity. UV radiation can cause the gelcoat to fade and become brittle over time. To mitigate this, consider using a boat cover when the vessel is not in use, especially during extended periods of storage. This simple step can significantly reduce the impact of UV rays and slow down the degradation process. Additionally, applying a marine-grade wax or sealant can provide an extra layer of protection, enhancing the boat's resistance to UV damage and environmental factors.

Regular inspections are also vital to identifying and addressing potential issues early on. Check for any signs of damage, such as cracks, chips, or delamination, especially in areas prone to impact or stress, like the bow and stern. Keep an eye on the boat's hardware, such as fasteners and hinges, ensuring they remain tight and secure. Regular maintenance will not only extend the boat's lifespan but also ensure its structural integrity and safety.

In conclusion, proper care and maintenance are essential to ensuring the long-term performance and longevity of a fiberglass boat. By implementing a regular cleaning routine, providing sun protection, and conducting thorough inspections, boat owners can significantly reduce the effects of degradation. With the right care, a fiberglass boat can remain in excellent condition, offering a reliable and enjoyable boating experience for many years.

Delavan Boat Launch: Veterans Discounts Denied, Why?

You may want to see also

Frequently asked questions

Fiberglass boats, while known for their durability, can indeed degrade over time due to various factors. The material is susceptible to UV radiation from the sun, which can cause the fibers to break down and the gelcoat to fade. Additionally, exposure to saltwater and harsh chemicals can accelerate degradation.

Common signs of fiberglass degradation include cracks, chips, or delamination in the gelcoat. You might also notice water seeping into the boat's structure, leading to potential corrosion and structural issues. Regular inspections and maintenance are crucial to identify and address these problems early on.

Absolutely! Regular maintenance is key to preserving the integrity of a fiberglass boat. This includes washing and rinsing the boat after saltwater exposure, applying marine-grade wax or protective coatings, and promptly repairing any damage to prevent further deterioration.

Upgrading the boat's gelcoat with a more UV-resistant material can provide long-term benefits. Additionally, regular repainting every few years can help protect the fiberglass from UV damage and maintain its appearance. Proper storage and handling, especially in harsh marine environments, can also significantly contribute to the boat's longevity.