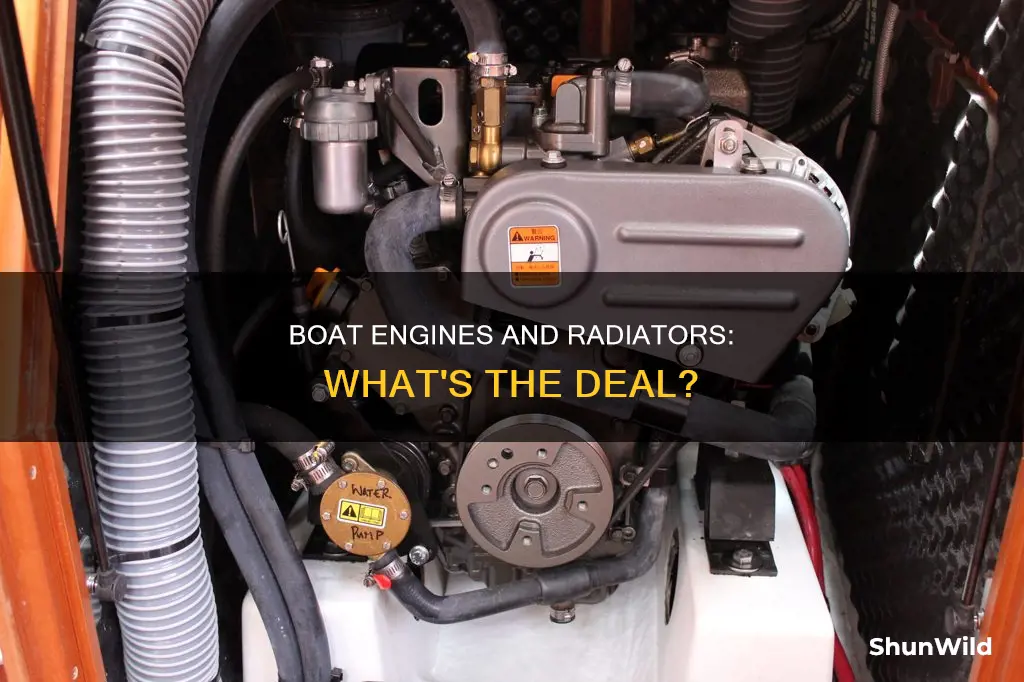

Marine engines are cooled using a variety of methods, but do boat engines have radiators? The short answer is no. Radiators are not used because there is no airflow available to cool them. Instead, boat engines use water-based cooling systems, either pumping water directly from the surrounding body of water (known as a raw water system) or using a closed-loop system with a heat exchanger.

What You'll Learn

- Boat engines don't use radiators because there is no airflow available to cool them

- Radiators that cool by exposing them to water are called heat exchangers

- Heat exchangers are more effective than radiators because water transfers heat better than air

- Heat exchangers are also coupled with oil coolers and transmission oil coolers

- Closed-loop systems are available for boat engines but are not recommended for use in saltwater

Boat engines don't use radiators because there is no airflow available to cool them

Marine engines do not use radiators because there is no airflow available to cool them. Instead, they use a water-based cooling system. This is because boats are designed to keep water out, which makes it difficult to provide enough airflow for cooling and combustion.

A marine engine works at close to its rated load almost all the time, unlike an automotive engine, which only works at full load when accelerating or climbing a hill. An automotive engine benefits from additional forced airflow across the radiator when travelling at speed, which would generally correspond with high-load conditions.

Marine engines use a captive amount of freshwater (coolant) that is continually circulated through a heat exchanger, which maintains the engine at a temperature set by the thermostat. Usually, this is between 170 and 180 degrees.

The raw water is pumped from the sea to a heat exchanger tube where coils filled with fresh water (coolant) are surrounded by flowing raw water (seawater). The cold raw water then cools the hot fresh water that is keeping the engine from overheating. Raw water passes through the heat exchanger only once before it is expelled back into the sea, while the fresh water continues to recirculate.

There are a few different types of cooling systems used in boats. One is a raw water system, where water is drawn up through a seacock by a water pump. The water then flows through the engine and directly out the exhaust. This cooler water absorbs heat from the engine to help keep it cool.

Another type is an enclosed cooling system, which uses a small tank on top of the engine that combines fresh water and coolant. This fresh water is circulated through the engine and through a heat exchanger. The raw water is pumped through the heat exchanger, where it absorbs heat from the fresh water, before being pumped out through the exhaust.

A third type is a closed-loop system, which uses a water-to-water heat exchanger instead of a radiator. This is a freshwater cooling system, which is a good option for saltwater use.

The main advantage of the enclosed system over the raw water system is extreme, especially when operating in saltwater. Saltwater tends to build up a corrosive scale when the engine operates above 140 degrees. In a raw water system, this scale builds up inside the engine's water jacket and ports, leading to restricted water flow and engine overheating. In an enclosed system, the water that flows through the engine's water jacket and ports is a combination of fresh water and coolant, while the raw water only flows through the heat exchanger.

Overall, while radiators are not used in boat engines due to a lack of available airflow, there are various effective water-based cooling systems that are commonly used instead.

Hooper's Vessel in Jaws: Unraveling the Mystery Boat

You may want to see also

Radiators that cool by exposing them to water are called heat exchangers

Radiators are heat exchangers used to cool internal combustion engines. They are commonly used in automobiles, piston-engined aircraft, railway locomotives, motorcycles, and stationary generating plants. Radiators are also used to cool the engines of watercraft, but these are usually liquid-liquid heat exchangers.

Liquid-cooled internal combustion engines have a liquid (usually water-based) engine coolant circulated through the engine block and cylinder head, where it is heated, then through a radiator where it loses heat to the atmosphere, and then returned to the engine. Radiators are designed to transfer thermal energy from one medium to another. In the case of internal combustion engines, the radiator transfers heat from the coolant to the passing air.

In the case of boats, the radiator is a heat exchanger that uses the relatively cool seawater, described as raw water, to cool the hot fresh water (coolant) that is keeping the engine from overheating. The raw water is pumped from the sea to a heat exchanger tube where coils filled with fresh water (coolant) are surrounded by flowing raw water (seawater). The cold raw water now cools the hot fresh water, which continues to recirculate. As the raw water exits the heat exchanger, it mixes with the exhaust gases in the muffler and is pumped out of the back of the boat.

A heat exchanger that cools by exposing it to water is a more effective method of cooling a boat engine than using a radiator and fan, as the water provides a much larger heat sink. This is why radiators are not commonly used for boat engines.

Evolution of Boat Trailers: When Did They Start Having Add-ons?

You may want to see also

Heat exchangers are more effective than radiators because water transfers heat better than air

Marine engines, particularly inboard engines, are often cooled using a heat exchanger and a closed cooling system. This is because boats are built to keep water out, so there is limited airflow available to cool a radiator. In a closed cooling system, a captive amount of freshwater (coolant) is continually circulated through a heat exchanger that maintains the engine at a temperature set by the thermostat. Usually, this is between 170 and 180 degrees.

The raw water system circulates water through the engine water jacket, which flows through the block, head, and manifold. This water absorbs the heat from the engine and is exhausted overboard. The enclosed system circulates fresh water and coolant through the engine water jacket and through a heat exchanger. This fresh water absorbs the heat of the engine. The raw water is also pumped through the heat exchanger, where it absorbs some of the heat from the fresh water and is then pumped out.

The main advantage of the enclosed system over the raw water system is that it prevents the buildup of corrosive scale inside the engine when operating in salt water. When the scaling builds to the point that water flow is restricted, the engine starts to overheat. This can lead to having to replace the engine. In the enclosed system, the water that flows through the engine’s water jacket and ports is the fresh water and coolant. The only part the raw water flows through is the heat exchanger. While the same scaling occurs, it is much less expensive to replace the heat exchanger than the engine.

Boat Websites and Hidden Prices: Why the Secrecy?

You may want to see also

Heat exchangers are also coupled with oil coolers and transmission oil coolers

Marine engines do not have radiators because there is no airflow available to cool them. Instead, they use a water-to-water heat exchanger, also known as a freshwater cooling system. This system is similar to the closed cooling system used in cars, where a captive amount of freshwater (coolant) is continually circulated through a heat exchanger to maintain the engine at a temperature set by the thermostat.

In a heat exchanger system, the raw water (seawater) is pumped from the sea to a heat exchanger tube where coils filled with fresh water (coolant) are surrounded by flowing raw water. The cold raw water absorbs heat from the hot fresh water, which is keeping the engine from overheating. The raw water passes through the heat exchanger only once before being expelled back into the sea, while the fresh water continues to recirculate.

The advantages of a heat exchanger system are significant, especially when operating in salt water. Salt water tends to build up a corrosive scale when the engine operates above 140 degrees Fahrenheit. In a raw water cooling system, this scale builds up inside the engine, leading to restricted water flow and eventual engine overheating. With a heat exchanger system, the water that flows through the engine's water jacket and ports is a mixture of fresh water and coolant. The only part that the raw water flows through is the heat exchanger, where the same scaling occurs. However, when water flow becomes restricted and the engine begins to overheat, it is possible to "acid boil" the scale out of the heat exchanger and continue to use it.

In summary, heat exchangers coupled with oil coolers and transmission oil coolers offer a more effective and reliable solution for cooling boat engines than radiators. They provide better heat dissipation, protect against corrosion, and are easier to maintain, making them ideal for both freshwater and saltwater applications.

PFD Requirements: Pedal Boats and Coast Guard

You may want to see also

Closed-loop systems are available for boat engines but are not recommended for use in saltwater

Closed-loop cooling systems, also known as enclosed cooling systems, are available for boat engines. These systems use a special coolant fluid that circulates through the engine in a closed loop, similar to a car's radiator system. The coolant fluid absorbs the heat from the engine and then transfers it to a heat exchanger, which is cooled by the surrounding water. This process keeps the engine at the proper temperature without relying on the temperature of the water the boat is in.

While closed-loop systems offer several benefits, they are not recommended for use in saltwater due to the risk of corrosion. Saltwater can cause a build-up of corrosive scale, which can restrict water flow and lead to engine overheating. This build-up is difficult to remove and can eventually require expensive engine repairs or replacements.

In contrast, open-loop cooling systems use the surrounding water to directly cool the engine. While this method is more susceptible to corrosion and debris, it is simpler, more reliable, and easier to service. For saltwater use, an open-loop system with proper maintenance, including regular flushing of the engine with fresh water, is generally a better option.

Additionally, the limited space and ventilation in boat engine compartments can make it challenging to install and maintain closed-loop systems. Electric fans, for example, may not provide sufficient cooling and can pose a fire hazard. Overall, while closed-loop systems have their advantages, they are not well-suited for the unique demands of saltwater boating.

Boat owners should carefully consider the specific requirements of their vessel and the environment in which it operates when deciding between a closed-loop or open-loop cooling system. Regular maintenance and adherence to safety protocols are crucial to ensuring the longevity and optimal performance of any marine engine.

The Finish Line: Mackinaw Race Course Unveiled

You may want to see also

Frequently asked questions

Boat engines don't have radiators because there is no airflow available to cool them. Instead, they use a water-to-water heat exchanger, also known as a closed-loop or freshwater cooling system.

Most newer marine engines use an enclosed cooling system. This system has a small tank on the top of the engine that uses a combination of freshwater and coolant. The freshwater is circulated through the engine and through a heat exchanger, where it is cooled by raw water (seawater).

A raw water cooling system draws water from the surrounding sea or lake into the engine through a seacock fitting. The water is then pumped through the engine's water jacket and ports by a mechanical water pump. The water absorbs heat from the engine and is then pumped out through the exhaust.

The advantages of an enclosed cooling system are significant, especially when operating in saltwater. Saltwater tends to build up a corrosive scale when the engine operates above 140°F. In a raw water system, this scale builds up inside the engine, leading to restricted water flow and eventual overheating. In an enclosed system, the water that flows through the engine is freshwater and coolant, reducing the risk of corrosion.

Yes, keel cooling is an option but these systems are generally installed on commercial vessels. Keel cooling uses a loop of piping on the outside of the hull to cool the engine with the surrounding water.