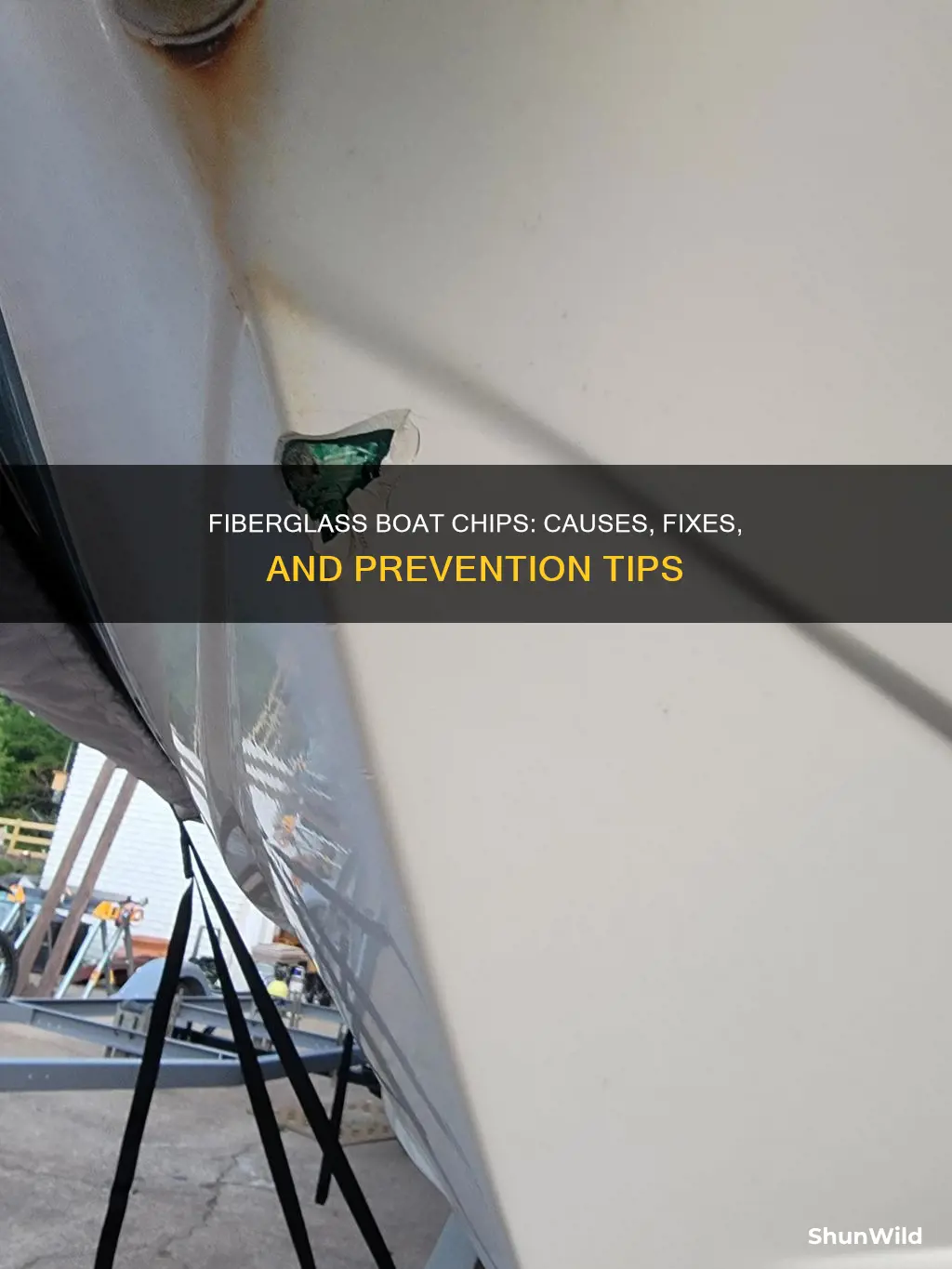

Are chips in a fiberglass boat? This question might seem odd, but it's a common concern for boat owners. Chips in the fiberglass hull can be a serious issue, as they can lead to water damage, corrosion, and even structural failure. Understanding the causes, effects, and solutions to this problem is essential for maintaining the integrity and longevity of your boat. In this article, we'll explore the reasons why chips occur, the potential consequences, and the steps you can take to prevent and repair them.

What You'll Learn

- Fiberglass Boat Chip Repair: Temporary fixes for small chips in the fiberglass hull

- Chip Prevention: Strategies to avoid chips during boat handling and storage

- Chip Inspection: Techniques to identify and assess the severity of boat chips

- Fiberglass Reinforcement: Methods to strengthen the fiberglass around chips for long-term durability

- Professional Repairs: When to seek expert help for complex chip repairs

Fiberglass Boat Chip Repair: Temporary fixes for small chips in the fiberglass hull

For small chips in the fiberglass hull of your boat, there are temporary fixes that can help you get back on the water quickly. These methods are ideal for minor damage and should not be relied upon for extensive repairs. Here's a step-by-step guide to help you tackle these issues:

Step 1: Assessment and Preparation

Before beginning any repair, it's crucial to assess the damage. Clean the chip area thoroughly to remove any dirt or debris. Use a mild detergent and water solution, ensuring the surface is dry before proceeding. This step is essential to ensure the repair material adheres properly.

Step 2: Filling the Chip

The primary goal is to fill the chip to create a smooth surface. You can use a fiberglass repair kit specifically designed for this purpose. These kits typically include a filler compound and a hardener. Mix the compound according to the manufacturer's instructions, ensuring it's neither too runny nor too thick. Apply the filler generously over the chip, ensuring it's level with the surrounding surface. Allow it to cure according to the kit's guidelines, which may take several hours.

Step 3: Sanding and Smoothing

Once the filler is cured, lightly sand the area to create a smooth transition between the repair and the original surface. Use fine-grit sandpaper (600-1200 grit) to avoid further damaging the fiberglass. After sanding, wipe away any dust and ensure the surface is clean and ready for the next step.

Step 4: Priming and Painting (Optional)

If you plan to repaint the affected area, apply a suitable marine primer first. This step is crucial to ensure the new paint adheres properly. Allow the primer to dry completely, then apply your chosen marine paint. This process will help camouflage the repair and restore the boat's appearance.

Temporary Fix Considerations:

It's important to remember that these temporary fixes are just that—temporary. The repair may not be as strong as the original fiberglass and could require further attention in the future. For more extensive damage, consulting a professional marine fiberglass repair specialist is recommended to ensure a long-lasting solution.

Remember, when dealing with any boat repairs, it's always best to follow manufacturer guidelines and seek professional advice for optimal results.

The Art of Naming Boats: A Cultural Tradition Explored

You may want to see also

Chip Prevention: Strategies to avoid chips during boat handling and storage

Chips and dings on a fiberglass boat can be a real eyesore and may even compromise the structural integrity of the vessel if left unattended. Fiberglass, being a composite material, is relatively delicate and prone to damage from sharp objects, accidental impacts, and environmental factors. Therefore, implementing preventive measures is crucial for boat owners to maintain the aesthetics and longevity of their fiberglass boats. Here are some strategies to avoid chips during boat handling and storage:

Secure Your Boat: Before transporting your boat, ensure that all loose items, such as fishing gear, anchors, and toys, are safely stowed away. These items can become projectiles during transit, causing scratches and chips. Use tie-downs and straps to secure the boat in the trailer or on the trailer bed. Pay extra attention to the areas around the fuel tanks, as sharp edges or impacts can lead to costly repairs.

Use Soft Tie-Downs: Opt for soft, padded tie-downs or webbing straps when securing your boat. These materials provide a cushion and reduce the risk of scratching the fiberglass surface. Avoid using sharp-edged ropes or chains that can easily cut into the boat's finish. Additionally, consider using wheel chocks to prevent the trailer from moving, especially on inclines, to minimize the chances of accidental damage.

Handle with Care: When loading or unloading the boat from the water, exercise caution. Use a dock or ramp with a smooth surface to avoid sharp edges that could scratch the hull. Lift the boat with a partner or use mechanical aids to reduce the risk of injury and potential damage. Always approach the boat's sides and transom with care, as these areas are susceptible to chips and dings.

Regular Maintenance and Inspection: Develop a regular maintenance routine to inspect your boat for any existing chips or potential problem areas. Keep an eye on the boat's surface for any signs of wear and tear, especially around the anchor points, tie-down locations, and areas where the boat rubs against the trailer. Address any minor issues promptly to prevent further damage. Regular cleaning and waxing can also help protect the fiberglass surface, making it more resistant to scratches and chips.

Storage Considerations: Proper storage is essential to prevent chips and dings. If possible, store your boat in a dry, covered area, away from direct sunlight and harsh weather conditions. If outdoor storage is necessary, ensure the boat is properly covered with a marine-grade fabric or a custom-fitted cover. Regularly inspect the cover for tears or damage and replace it if needed. Additionally, consider using boat covers with a foam padding layer to provide extra protection during storage.

By implementing these preventive measures, boat owners can significantly reduce the likelihood of chips and dings, ensuring their fiberglass boats remain in excellent condition. Being mindful of potential hazards and adopting a proactive approach to maintenance will contribute to the long-term beauty and structural integrity of the vessel.

The Boat Trip: Miami to Nassau Distance Explored

You may want to see also

Chip Inspection: Techniques to identify and assess the severity of boat chips

When it comes to fiberglass boats, chips and minor damage can be a common occurrence, especially in the hull and deck areas. These chips can range from small, barely noticeable dings to more significant damage that may compromise the boat's structural integrity. Identifying and assessing the severity of these chips is crucial for ensuring the boat's safety and longevity. Here are some techniques to help you inspect and evaluate the chips:

Visual Inspection: Start by thoroughly examining the boat's surface where the chips are located. Look for any visible signs of damage, such as small pits, cracks, or raised fibers. Pay close attention to the color and texture of the affected area. Chips in fiberglass can sometimes create a visible change in color, often appearing as a lighter or darker spot compared to the surrounding material. Use a magnifying glass or a bright flashlight to get a closer look at the chip and its surrounding area.

Touch and Feel: Your sense of touch can provide valuable information during the inspection. Gently run your finger or a soft cloth over the chip and the adjacent areas. Chips may feel smoother or rougher than the surrounding fiberglass. Look for any sharp edges or protruding fibers that could indicate more severe damage. If the chip is deep or has caused the fibers to separate, you might feel a noticeable change in texture.

Water Testing: Water can be a useful tool for identifying chips and their severity. Spray a small amount of water onto the affected area and observe how it behaves. Chips that are small and shallow may not allow water to penetrate, while deeper damage could cause water to seep in. If water enters the boat through the chip, it indicates a more serious issue that requires immediate attention.

Comparative Analysis: Compare the damaged area with similar sections of the boat that are in good condition. This visual comparison can help you assess the extent of the damage. Look for any patterns or differences in the way the fibers are aligned or the color of the material. A significant deviation from the normal appearance and texture suggests a more severe chip.

Professional Assessment: For larger or more complex chips, it is recommended to seek the expertise of a professional marine technician or a fiberglass repair specialist. They have the knowledge and tools to provide a detailed evaluation and suggest appropriate repair methods. These professionals can also advise on the potential long-term consequences of the chip and whether it requires immediate action or can be monitored for now.

Remember, proper chip inspection is essential for maintaining the structural integrity and appearance of your fiberglass boat. By using these techniques, you can identify and address chips effectively, ensuring a safe and enjoyable boating experience.

Docking Your Boat: City Winery Access Guide

You may want to see also

Fiberglass Reinforcement: Methods to strengthen the fiberglass around chips for long-term durability

When it comes to maintaining the structural integrity of a fiberglass boat, addressing chips and damage is crucial. Fiberglass, while durable, can be susceptible to wear and tear, especially in areas prone to impact or abrasion. Chips in the fiberglass can not only compromise the boat's appearance but also potentially weaken its structure over time. Reinforcing these damaged areas is essential to ensure the boat's longevity and safety. Here are some methods to strengthen the fiberglass around chips for long-term durability:

- Filling and Sanding: The first step is to fill the chip with a suitable epoxy-based filler. This filler should be carefully applied to create a smooth and level surface. Once the filler is set, sand it down to match the surrounding fiberglass. This process ensures that the chip is seamlessly integrated back into the boat's structure. It's important to use a fine-grit sandpaper to avoid further damaging the fiberglass. After sanding, wipe away any dust and ensure the surface is clean and ready for the next step.

- Reinforcement with Fabric: After the filler has cured, it's time to reinforce the area. Cut a piece of fiberglass cloth (preferably the same type as the boat's construction) slightly larger than the filled chip. Apply a thin layer of epoxy resin to the cloth and carefully lay it over the filled area. Ensure the cloth is properly saturated with the resin and smooth out any wrinkles. This process adds strength and structural support to the damaged area. Allow the resin to cure according to the manufacturer's instructions.

- Using Structural Adhesives: For more severe damage or larger chips, structural adhesives can be employed. These adhesives are specifically designed to bond fiberglass components together. Apply a generous amount of the adhesive to the chip and surrounding area, ensuring complete coverage. Then, carefully place a piece of fiberglass reinforcement, such as a rod or tape, onto the adhesive. This provides additional strength and helps distribute stress evenly. Allow the adhesive to cure thoroughly before subjecting the boat to normal use.

- Gel-Coat Application: Consider applying a gel-coat to the reinforced area for added protection and aesthetics. Gel-coat is a clear or colored epoxy resin that can be sprayed or rolled onto the surface. It provides a smooth, glossy finish and offers an extra layer of defense against UV rays and environmental damage. This step is particularly useful for cosmetic improvements and adding an extra layer of durability.

By following these reinforcement methods, boat owners can effectively address chips in their fiberglass boats. Proper reinforcement ensures that the boat remains structurally sound and aesthetically pleasing for years to come. Regular maintenance and prompt attention to any damage will contribute to the overall longevity of the vessel.

Transmission Ratio: Engine RPM and Boat Speed Relationship

You may want to see also

Professional Repairs: When to seek expert help for complex chip repairs

When it comes to maintaining a fiberglass boat, addressing chips and damage promptly is crucial to prevent further issues. While some minor chips can be tackled by boat owners, there are instances where seeking professional repair services is the best course of action. Here's a guide to help you understand when to opt for expert help for complex chip repairs.

Assessing the Damage: Before deciding on a repair approach, it's essential to evaluate the severity of the chip. Small, superficial chips might not require immediate professional attention. These minor damages can often be filled and sanded down to restore the boat's smooth surface. However, if the chip is deep, affecting the fiberglass's structural integrity, or if it's located in a critical area like the hull or deck, professional intervention is necessary.

Complexity of the Repair: Fiberglass repairs can vary in complexity. Simple chips may only need a small patch and a touch-up of the gelcoat or paint. But for more intricate damage, such as holes, cracks, or extensive gelcoat damage, a professional's expertise is invaluable. Experienced technicians have the skills to assess the extent of the damage, remove affected material, and apply the appropriate repair techniques, ensuring a seamless and long-lasting fix.

Safety and Structural Concerns: One of the primary reasons to seek professional help is to ensure the safety and structural integrity of the boat. Deep chips or those near critical components can compromise the boat's strength and stability. Professionals understand the structural implications of various repair methods and can employ techniques that maintain or even enhance the boat's structural integrity. This is especially important for older boats or those with unique designs.

Time and Convenience: Repairing a fiberglass boat, especially complex issues, can be time-consuming. It requires specialized tools, materials, and techniques that professionals possess. By hiring experts, you save time and effort, as they can complete the repair efficiently and effectively. Additionally, professionals often have access to high-quality materials and can provide a warranty on their work, giving you peace of mind.

In summary, while minor chips can be handled by boat owners, complex repairs demand the skills and experience of professionals. They can accurately assess the damage, provide appropriate solutions, and ensure the boat's safety and longevity. Remember, when it comes to fiberglass boat maintenance, it's often better to invest in expert help for complex chip repairs to avoid potential complications and ensure a professional-quality finish.

Boat Dock Decor: Creative Ways to Enhance Your Waterfront

You may want to see also

Frequently asked questions

Chips in a fiberglass boat can lead to structural weaknesses and potential water leaks. Over time, these chips may cause the boat's hull to weaken, affecting its overall integrity and safety. Additionally, chips can create entry points for water, leading to flooding and potential damage to the boat's interior and electrical systems.

Visual inspection is the primary method. Look for any visible cracks, small holes, or discolored areas on the boat's surface. Chips may also be felt as small indentations or rough spots when running your hand over the hull. Regular maintenance and inspections can help detect chips early.

Yes, fiberglass chips can be repaired. The process typically involves cleaning the area, applying a specialized fiberglass repair kit, and using a gel coat to match the surrounding surface. It is recommended to seek professional help for effective and long-lasting repairs.

Chips can occur due to various reasons. Impact damage from collisions with objects, improper handling during maintenance, or even natural wear and tear over time can lead to chips. Environmental factors like UV radiation and chemical exposure can also contribute to the degradation of the fiberglass.

Regular maintenance and care are essential. Keep the boat's surface clean and free from debris. Use marine-grade protective coatings and sealants to enhance the boat's durability. Avoid harsh cleaning agents that may damage the fiberglass. Additionally, be cautious during storage and transportation to prevent accidental impacts.